Cold Forging Factory for OEM Custom Manufacturing

SIMIS Cold Forging Factory Introduction

SIMIS Cold Forging Factory specializes in high-precision metal cold forming and precision cold forgings. The plant integrates die design and manufacturing, wire and billet pre-treatment, cold extrusion and cold heading forming, heat treatment, precision machining, and inspection.

SIMIS primarily produces aluminum alloy, low- and medium-carbon steel, and copper alloy (mainly cold extrusion) cold forged components.SIMIS focuses on delivering high-accuracy, high-strength, and mass-production cold forging solutions for industries including automotive, motorcycle, fasteners, hydraulics, electronics, motors, hardware tools.

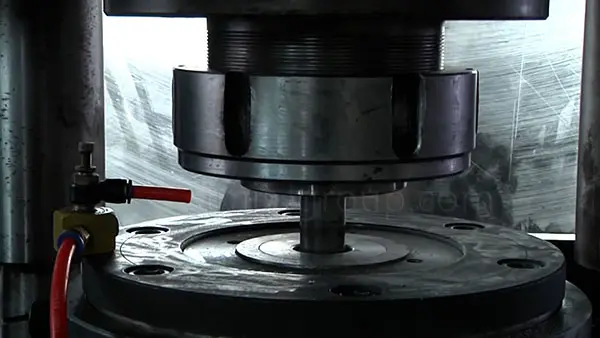

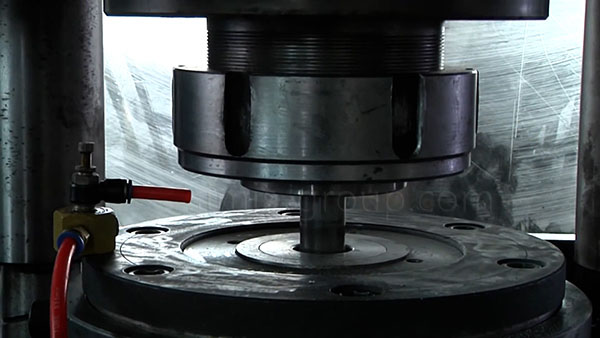

Main Forming Equipment: Multi-station cold heading machines (3–6 stations), cold extrusion presses (300–1200 tons)

Auxiliary Equipment: Spheroidizing annealing furnaces, straightening machines, peeling machines, automatic feeders

Die Manufacturing: CNC lathes, machining centers, wire cutting, grinding, polishing machines

Heat Treatment Equipment: Vacuum heat treatment furnace, continuous mesh belt furnace (±5°C precision)

Forging Weight Range: 5 g – 3 kg

Max. Dimensions: Diameter ≤ 100 mm, Length ≤ 200 mm (depending on geometry)

High dimensional accuracy (up to IT8 tolerance grade)

Excellent surface finish, often requiring little or no machining

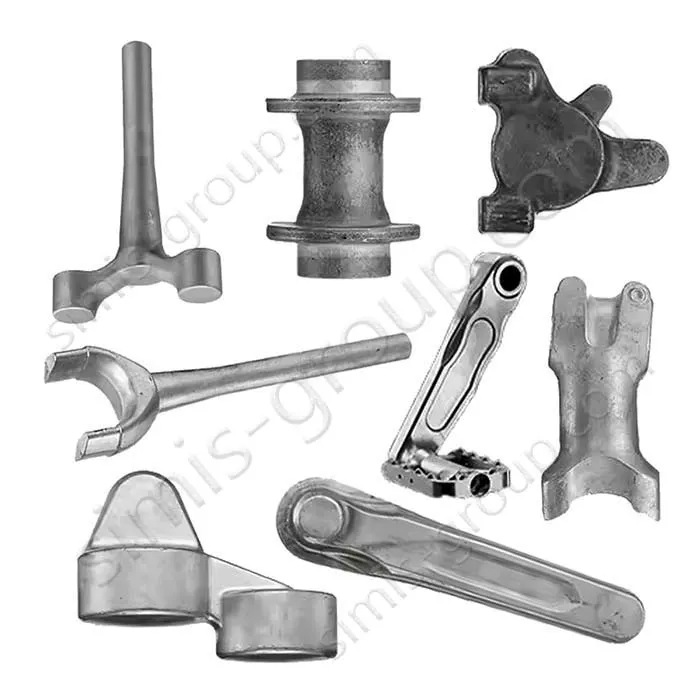

OEM Custom Cold Forging Parts

Cold Forging Process for Custom Metal Parts

Cold forging process overview

Cold forging is to apply pressure to metal at room temperature to make it plastically deform and achieve the desired shape. Cold forging does not require heating of the metal blank, which can make the forgings have higher dimensional accuracy and surface quality. Cold forging is used in the manufacture of precision parts such as automotive parts, electronic accessories, and machinery.

1. Cold forging material selection

Cold forging requires materials with good room-temperature ductility, stable plastic flow, and relatively low yield strength to avoid cracking during deformation. Commonly used materials include: Aluminum alloys, Low-carbon steel, medium-carbon steel, Copper and copper alloys (mainly for cold extrusion).

Material selection is determined by part geometry, deformation degree, and production volume, ensuring stable forming and acceptable tool life.

2. Billet preparation

The selected metal materials are processed into suitable billets, such as slugs, cylinders, or bars. Surface contaminants including oxide layers, oil, and debris are removed to ensure consistent forming quality and to reduce die wear.

Proper lubrication is applied to the billet surface, especially for cold extrusion operations, to control friction and material flow.

3. Die design

High-strength tool steel dies are designed according to the part geometry, material characteristics, and selected cold forging process (cold heading, cold extrusion, or combined forming).

4. Cold forging / cold extrusion forming

The billet is formed under high pressure using cold forging equipment such as mechanical presses, hydraulic presses, or multi-station cold forging machines. Forming forces typically range from tens to hundreds of tons, depending on material and part complexity.

Cold heading is mainly used for upsetting and external shape formation.

Cold extrusion (forward, backward, or combined extrusion) is used to form deep cavities, hollow sections, and complex internal geometries.

5. Forging cooling

After the part is formed, it needs to be naturally cooled to room temperature. The uniformity and stability of the forging can be guaranteed by controlling the cooling rate.

6. Heat treatment

Cold forgings need to undergo heat treatment processes such as annealing, normalizing, quenching and tempering to improve the mechanical properties of forgings such as strength and wear resistance.

Heat treatment is commonly applied to steel cold forgings, while aluminum alloy cold forgings may require solution treatment and aging if applicable.

7. Subsequent processing and surface treatment

Finishing: Cold forging can provide higher dimensional accuracy, but some parts still need to go through finishing processes such as turning, milling, drilling, etc. to ensure that the final parts meet the accuracy requirements.

Surface treatment: Sandblasting, polishing, painting or electroplating are performed to improve surface finish, corrosion resistance and wear resistance.

Available Materials for Cold Forging Applications

What metal parts can be forged in Simis Cold Forging Factory?

Unlike hot forging, cold forging relies on the inherent ductility of the material and work hardening to achieve final shape. Simis cold forging plant can forge parts made of low carbon steel, medium carbon steel, and aluminum alloys. The process produces components with excellent dimensional accuracy, smooth surface finish, and superior mechanical properties, particularly strength and fatigue resistance due to strain hardening. Cold forging is best suited for high-volume production of relatively small, axisymmetric or simple-shaped components.

| Material Category | Why It Is Suitable for Cold Forging | Simis Cold Forging Plant Typical Applications | Simis Cold Forging Plant Common Grades |

| Aluminum Alloys | Excellent ductility at room temperature and low forming resistance. Cold forging enables near-net-shape production with superior surface finish and enhanced strength through work hardening; Cold extrusion of aluminum alloys is not only labor-saving but also produces an extremely high surface finish. | Heat Sink, automotive lightweight components, housings, shafts, structural parts, air conditioning manifolds, filter housings, electronic radiators, and muffler housings. | 1060, 6061, 6063, 7075 |

| Low-Carbon Steel | High ductility allows large plastic deformation without cracking. Cold forging produces high-strength, dimensionally consistent parts for high-volume production | Fasteners, pins, shafts | AISI 1010, 1018, 1020 |

| Medium-Carbon Steel | Medium-carbon steels can be cold forged under controlled conditions, typically using multi-stage forming and intermediate annealing. Suitable mainly for small, simple geometries where enhanced strength is required | Small shafts, pins, mechanical connectors, high-strength bolts, drive shafts, gear blanks. | AISI 1035, 1040, 1045 |