Open-die Forging Factory for OEM Custom Manufacturing

Simis Open-die Forging Factory Introduction

SIMIS Open Die Forging Factory specializing in medium and large-size open die forgings (free forgings). The plant integrates heating, free forging, heat treatment, rough machining, and inspection, and is capable of producing a wide range of carbon steel, alloy steel, stainless steel, and non-ferrous metal forgings.SIMIS provides high-strength, high-toughness, and high-reliability forged components for industries such as construction machinery, petrochemical, mining, wind energy, metallurgy, marine, and rail transportation.

Main Forging Press: 4,000-ton and 6,000-ton hydraulic open die forging press (with manipulator)

Auxiliary Presses: 1,000-ton and 1,600-ton hydraulic presses

Heating Equipment: Gas furnace (max. charge 15 tons), Electric resistance furnace: (temperature control ±5°C)

Heat Treatment Furnaces: Normalizing, annealing, and quenching furnaces: (length ≤ 6 m)

Cranes Max. lifting capacity: 25 tons

Forging Weight Range: 50 kg – 8,000 kg

Max. Dimensions Diameter: ≤ 1.2 m, Length ≤ 6.0 m

Open-die Forging Process for Custom Metal Parts

Open-die forging process overview:

Open-die forging is a metalworking process where heated metal billets are shaped under repeated hammer blows or pressure without being fully confined within a die. Open-die forging process allows for greater flexibility in forging large or customized parts while improving the metal's mechanical properties.

1. Material selection and preparation

Select the appropriate metal material according to the required mechanical properties of the part, cut it into billets of specified size or weight, and remove contaminants, rust or oxide layers from the billets.

2. Heating the billet

The metal billet is uniformly heated to a specified temperature in a furnace to increase its deformation plasticity.

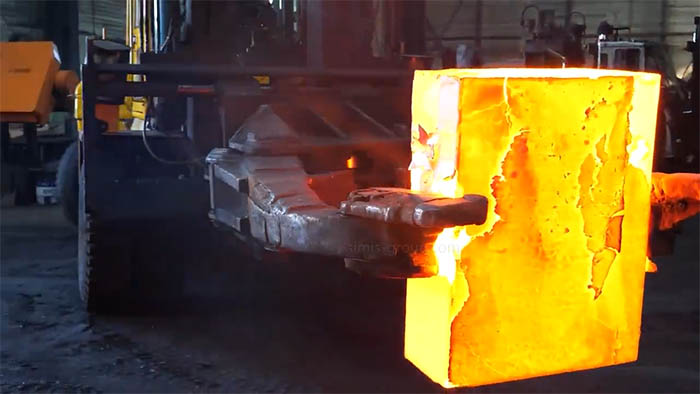

3. Forging operation

The heated metal billet is placed on a flat or slightly contoured die and deformed using controlled blows of a hammer or press. The shape of the part is forged through operations such as upsetting, stretching (elongation), bending, punching, twisting, and flattening (the workpiece is not constrained in the transverse direction and can be flexibly formed).

· Upsetting: used to shorten the length of the blank, increase the cross-sectional area, make it closer to the final shape, and improve the material organization.

· Drawing Out: Increase the length of the blank and reduce the cross-section, mainly used in the manufacture of shaft and rod parts.

· Punching: Increase the length of the blank and reduce the cross-section, mainly used in the manufacture of shaft and rod parts.

· Punching: Use a punch to apply pressure on the blank to form a hole, used to make annular or perforated parts.

· Reaming: Expand the workpiece after punching to obtain a larger inner diameter and uniform wall thickness.

· Bending: Bend the blank into the desired shape, suitable for the manufacture of hook-shaped, elbow and other parts.

· Twisting: Rotate the blank around the axis at a certain angle, suitable for parts that require a specific twisted shape.

4. Cooling

The forged parts are gradually cooled to minimize internal stress and prevent cracking.

Some forged parts can be directly transferred to the heat treatment step to enhance performance.

5. Heat treatment

Forgings are heat treated by normalizing, annealing, quenching, and tempering to improve the mechanical properties of forgings, release internal stress, and refine the grain structure.

6. Quality Inspection

Strictly inspect and correct the size, shape and performance of forgings to ensure that the products meet the design requirements.

7. Finishing and Final Processing

Surface treatment and subsequent processing of forgings are carried out according to customer requirements.

8. Quality Inspection

Comprehensive measurement is carried out through surface quality inspection, dimension inspection, mechanical property test and other quality inspection methods to ensure that the forgings meet the requirements of the design drawings.

Available Materials for Open-die Forging Applications

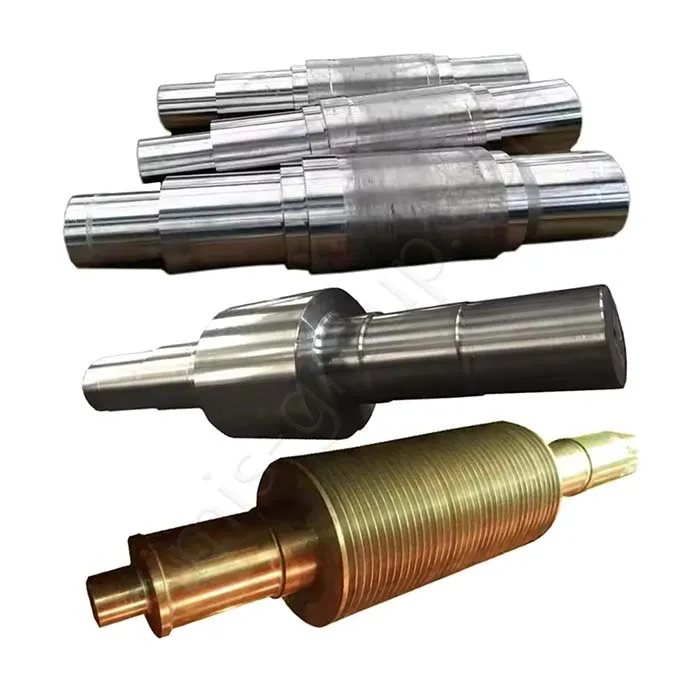

What metal parts can be forged in Simis Open-die Forging Factory?

Open-die forging is particularly suited for producing large, high-strength, and structurally critical components with excellent mechanical properties, including isotropy, impact toughness, and fatigue resistance. Our Open-die forging capabilities primarily cover stainless steels, carbon steel and alloy steels. . Open-die forging process allows precise control of grain flow, making it ideal for components subjected to high stresses.

| Material Category | Why It Is Suitable for Open-Die Forging | Simis Open-Die Forging Factory Typical Applications | Simis Open-Die Forging Factory Common Grades |

| Carbon Steel | Good hot deformability and cost-effective. Open-die forging refines grain structure, increases strength and toughness, and reduces internal defects | Shafts, axles, large gears, structural components | AISI 1045, 1050, 1060; EN C45, C50 |

| Stainless Steel | Austenitic and precipitation-hardening stainless steels can be open-die forged to improve toughness, ductility, and corrosion resistance. Careful temperature control prevents cracking and maintains corrosion performance | Chemical and food processing equipment, high-performance shafts, valve components, pump bodies | AISI 304, 316, 17-4PH; EN 1.4301, 1.4404, 1.4542 |

| Low-Alloy Steel | Alloying elements improve hardenability, strength, and wear resistance. Open-die forging produces large structural or pressure-bearing components with excellent toughness | Crane hooks, pressure vessel components, connecting rods, flanges | AISI 4140, 4340; EN 19, 42CrMo4 |

| High-Alloy Steel | Certain heat-resistant or high-strength steels can be forged for components subjected to high temperature and stress, provided precise process control | Turbine disks, aerospace shafts, high-performance mechanical parts | AISI 4145, 4340 modified, Inconel 718 |