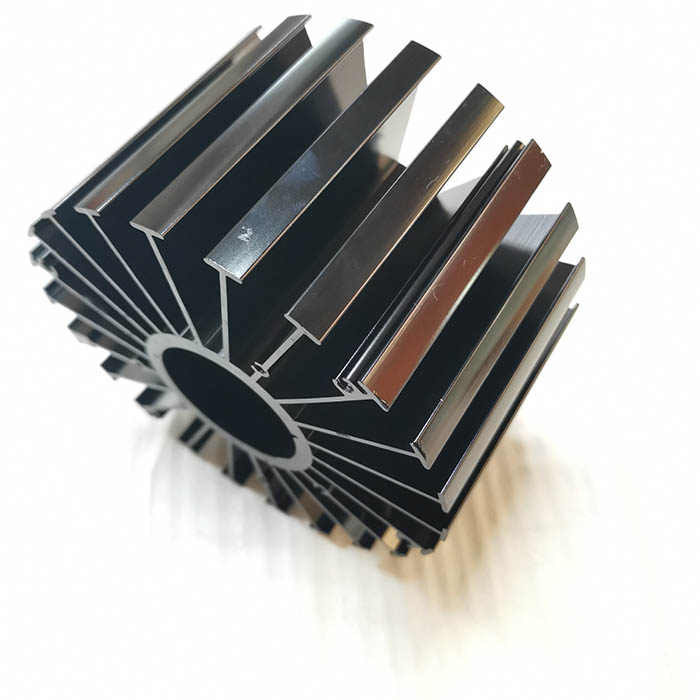

Custom Heat Sink Manufacturer

Heat Sink

China Simis Company is a specialized OEM custom manufacturer of Heat Sinks (Heat Dissipators) in electronic, LED lighting, and power conversion systems. The Heat Sink must efficiently absorb heat from the source and dissipate it through its fins into the surrounding medium (air or liquid). Its performance is dictated by the thermal conductivity of the material, the surface area of the fins, and the interface flatness.

To meet these requirements, the primary material is Aluminum Alloy and Copper Alloys (due to its excellent conductivity and low density), manufactured using several key processes: Pressure Die Casting for complex shapes and high volume; Extrusion for standardized fin geometries; and Cold Forging for maximizing fin density and material purity. Precision CNC Machining is mandatory for achieving the critical flatness and smoothness of the mounting base.

What Are the Manufacturing Processes for Custom Heat Sinks?

Our processes are selected to maximize the material's thermal properties while creating intricate, high-surface-area fin structures. The choice between extrusion and casting is determined by the required complexity, aspect ratio (fin height/gap), and production volume. We mainly adopt Pressure Die Casting, Extrusion, Cold Forging, Skived Fin and Precision CNC Machining for heat sink production.

| Manufacturing Process | Applicable Material Range | Application Focus for Heat Sinks | Core Advantage |

| Pressure Die Casting | Aluminum Alloy, Zinc Alloy | High-volume production of complex Heat Sinks with integrated mounting features, bosses, and non-uniform fins (e.g., LED light fixtures housing). | Highest production speed and the ability to form complex shapes that integrate multiple features into a single piece. |

| Extrusion | Aluminum Alloy | Standardized, straight-fin Heat Sinks of various widths and lengths; often the most cost-effective method for simple geometry. | Excellent thermal conductivity due to dense, continuous grain structure; easily scalable length. |

| Cold Forging | Aluminum Alloy, Copper Alloy | High-density pin fin or round fin Heat Sinks requiring the highest surface area-to-volume ratio and superior thermal performance. | Creates highly dense material with maximized fin height/thickness ratios, improving thermal transfer efficiency. |

| Skived Fin | Copper Alloy, Aluminum Alloy | Heat Sinks that require very thin, high-density fins that cannot be extruded or die-cast. | Creates extremely thin fins from a solid block, maximizing surface area for forced convection applications. |

| Precision CNC Machining | All Alloys | Mandatory finishing for the base contact surface to achieve optimal flatness (e.g., <0.05mm) and low surface roughness (Ra value). | Guarantees the critical interface quality for minimal thermal resistance between the heat source and the Heat Sink. |

How to Select the Right Material Type for Custom Heat Sinks?

The material must possess a high thermal conductivity (k, measured in W/m·K) to efficiently move heat from the source (base) to the dissipation surface (fins). We mainly provide Aluminum Alloy (Al 6063-Extruded, A 380-Die Cast) and Copper Alloy (C11000 series) for heat sink production according to different thermal performance requirements.

| Material Type | Thermal Conductivity (k) | Primary Performance Requirement |

| Aluminum Alloy (Al 6063 - Extruded) | High (typically 160 - 200W/m·K). | Best balance of cost, conductivity, and light weight for high-volume extrusion. |

| Aluminum Alloy (A 380 - Die Cast) | Moderate (typically90-110W/m·K). | Used when complex shapes and integrated features are needed, despite lower conductivity than extruded Al. |

| Copper Alloy (C11000 series) | Highest (typically385W/m·K). | Used for small, high-flux components (e.g., CPU core blocks) where thermal density is extreme; heaviest and most expensive option. |

What Precision Interface and Quality Assurance Measures Are Adopted for Heat Sinks?

The success of a heat sink depends on minimizing thermal resistance at the interface with the chip. This requires extreme precision in the base. Our core measures include base flatness and roughness control, dimensional accuracy guarantee, surface treatment and thermal performance testing.

·Base Flatness and Roughness:

Precision CNC machining or skiving of the contact base is critical to achieving extremely tight flatness tolerances (often <0.05mm) and low surface roughness. This ensures maximum contact area with the heat source and minimizes the thickness of the Thermal Interface Material (TIM).

·Dimensional Accuracy:

Accurate manufacturing of the fin geometry and density is required to ensure the heat sink meets the designed thermal resistance specification and air flow profile.

·Surface Treatment:

Anodizing (black or clear) is commonly applied to improve corrosion resistance and, for painted surfaces, slightly enhance radiative heat transfer.

·Thermal Performance Testing:

We provide validation using thermal resistance measurement equipment to confirm the heat sink meets the customer's specified ΔT (temperature rise) under a defined heat load (Watts) in a controlled environment.

What Are the Key Applications for Simis Custom Heat Sinks?

Heat Sinks are ubiquitous across any industry using electronics or converting high levels of power. Our custom heat sinks are deployed across systems where reliable thermal control is essential, covering electronics & IT, LED lighting, automotive and renewable energy sectors.

| Application Sector | Typical Component | Core Performance Needs | Simis Material/Process Focus |

| Electronics & IT | CPU Coolers, Server Rack Cooling, Power Supply Heat Sinks. | High Density, High Rth Performance, CNC Base Precision. | Aluminum Alloy (Extrusion/Cold Forging), Copper Alloy (Skived Fin). |

| LED Lighting | High-Bay Light Housings, Street Light Heat Sinks. | Weather Resistance, Complex Geometry, Large Surface Area (Natural Convection). | Aluminum Alloy (Pressure Die Casting). |

| Automotive | EV Battery Cooling Plates, Power Inverter Heat Sinks, ECU Housings. | Vibration Resistance, Corrosion Resistance, High-Volume Production. | Aluminum Alloy (Die Casting/Extrusion). |

| Renewable Energy | Solar Inverter Cooling Modules, Wind Turbine Converter Heat Sinks. | High Reliability, Large Scale, Outdoor Exposure Resistance. | Aluminum Alloy (Extrusion/Die Casting). |

What Are the Advantages of Simis OEM Custom Heat Sinks?

Partnering with Simis for custom heat sinks ensures optimal cooling performance, precision, and manufacturing efficiency. Our core advantages include process flexibility, low thermal resistance focus, integrated design support and integrated supply chain service.

·Process Flexibility (Extrusion vs. Casting):

We guide clients to the most suitable process—Extrusion for high conductivity/high aspect ratio or Die Casting for complex forms/integrated features—to meet both thermal and cost targets.

·Low Thermal Resistance Focus:

We specialize in post-casting / extrusion ultra-precision base machining to guarantee the required flatness and surface finish for minimal thermal contact resistance.

·Integrated Design Support:

We assist in optimizing fin design (density, thickness, orientation) based on the application's airflow constraints (natural convection vs. forced air).

·Integrated Supply Chain:

We offer a single source responsible for material selection (Al/Cu), forming (extrusion/casting), high-precision base machining, and final surface treatment.

How to Get a Quote for Custom Heat Sinks?

China Simis Company is your specialized partner for high-performance Heat Sinks, offering tailored manufacturing solutions—including die casting, cold forging, and specialized fin techniques—to meet your specific thermal management, volume, and cost requirements.

Please submit your 2D technical drawings, CAD models, required material and process (e.g., Aluminum Extrusion Heat Sink or Copper Cold Forged Heat Sink)), critical base flatness tolerance, and expected annual volume to our engineering department for a consultation and detailed quotation.