Custom Metal Parts For Mining Metallurgical

Custom castings and forgings are used in the mining and metal industry. They help with mining, transport, crushing, grinding, smelting, and support. They also aid in lifting, green production, and energy recovery. These parts offer high strength, wear resistance, and fight fatigue. This lets custom parts work well in high load, high impact, high heat, and corrosive places. This makes mining gear more reliable and last longer. It lowers repair costs. It also ensures efficient, safe, and clean production for the whole industry.

Mining Metallurgical Parts Classification

1. Mining equipment components

Mining equipment leads the production process. Castings and forgings make key parts for excavators, drill rigs, and other machines. This includes bucket teeth, buckets, drill rods, and rotating shafts.

They offer great strength, toughness, and wear resistance. This ensures the equipment works stably and well, even in complex ground and high-impact places.

Castings: Excavator bucket teeth, Bucket housings, Drill rig bases and supports

Forgings: Digging arm pins, Rotating shafts, Drill rod joints

2. Conveying system components

The conveying system is key for moving ore and raw materials. Castings and forgings are used in rollers, sprockets, shafts, and chains. Their high stiffness and resistance to wear ensure the system runs continuously for a long time. This lowers how often the system stops for repairs.

Castings: Conveyor rollers, Frames, Sprocket housings

Forgings: Chain segments, Drive shafts and couplings

3. Crushing and grinding equipment components

Crushing and grinding machines are vital for processing ore. Castings and forgings make parts like crusher housings, hammers, mill liners, and spindles.

Their high strength and wear resistance let the equipment handle the impact of ore and long-term wear. This ensures the ore process is stable and efficient.

Castings: Crusher housing, Mill liner, Bushing

Forgings: Crusher hammer, Mill bearing, Spindle

4. Smelting equipment components

Smelting equipment must work in places with high heat, high pressure, and high corrosion. Castings and forgings are used for furnace housings, support rods, valves, and slides.

These parts offer great high-temperature resistance, rust resistance, and high strength. This keeps smelting equipment running stably. It makes the equipment last longer and allows for high-temperature metal work.

Castings: Furnace shell, Air duct components, Cast steel slideway

Forgings: Furnace support rods, Forged valve components

5. Structural and support components

The strong structure of large mining and metal equipment needs support from castings and forgings. These include racks, bases, guides, bolts, and shafts.

These parts provide the needed stiffness and load capacity. This allows the equipment to run stably under heavy load conditions.

Castings: Large racks, Support bases, Sliding guides

Forgings: High-strength bolts, Connectors, Heavy-duty support shafts

6. Lifting and hoisting equipment components

Lifting and hoisting gear is key for moving things underground and fixing machines in mines. Castings and forgings are vital for parts like drums, winches, hooks, pulleys, and chain links.

Their high strength and fatigue resistance keep the equipment stable and safe. This is true even during non-stop, heavy-load work.

Castings: Winch wheels, Drum housings, Hooks, Pulley brackets

Forgings: Wire rope chucks, Lifting rings, Forged spindles, Chain links

7. Environmental protection and energy recovery system components

Green practices in mining and metal work need good environmental and energy recovery systems. Castings and forgings make parts like desulfurization tower shells, heat exchangers, fan blades, and energy recovery rotors.

Their resistance to rust, high heat, and high strength improves the equipment's stability and efficiency. This lowers energy use and environmental harm.

Castings: Flue gas desulfurization tower shell, Exhaust pipe, Waste heat boiler shell, Heat exchanger shell

Forgings: High-pressure fan blade shaft, Energy-saving valve body, Energy recovery rotor

Available Materials For Mining Metallurgical Parts

Cast Iron in Mining Machinery

Cast iron is used for parts that fight wear and absorb vibration in mining machines. Complex shapes are made using sand casting, precision casting, and heat treatment.

Gray Cast Iron

Gray cast iron is used for crusher frames, screen frames, mill liners, and support bases. It absorbs vibration well. This reduces machine shake while keeping machining accuracy.

Ductile Iron

Ductile iron is sand-casted and heat-treated. It makes crusher gearbox housings, mine wheel hubs, and hydraulic pump housings. Its high strength and toughness let it handle heavy loads and impacts.

Alloy Cast Iron

Alloy cast iron is made stronger with alloying and heat treatment. It is used for wear-resistant bushings, mill liners, scrapers, and roller sleeves. It is fit for high-wear, high-temperature work places.

Steel in Mining Machinery

Steel is used in mining machines for parts that carry loads, transmit power, and face high stress. Forging, casting, heat treatment, and machining make its strength and wear resistance better.

Carbon Steel

Carbon steel is used for crusher hammers, mine car frames, conveyor shafts, and gears. It handles high ipact and heavy loads.

Carbon Steel Parts: Crusher hammers, Mine car chassis, Conveyor roller shafts, Gears

Low-Alloy Steel

Low-alloy, high-strength steel is forged and welded. It is used for crusher frames, support beams, and large gears. It fights fatigue and handles heavy loads well.

Low-Alloy Steel Parts: Crusher frames, Support beams, Mine car load-bearing structures, Large gears

Cast Steel

Cast steel is used for gearbox housings, reducer housings, pump bodies, and large chassis parts. After casting, machining ensures the parts fit together precisely.

Cast Steel Parts: Gearbox housings, Reducer housings, Hydraulic pump bodies, Large chassis components

High Manganese Steel

High manganese steel fights wear very well. It is used for conveyor liners, crusher liners, and wear parts. It lasts longer in places with heavy loads and high wear.

High Manganese Steel Parts: Ore conveyor liners, Crusher liners, Wear parts

Stainless Steel

Stainless steel resists rust and chemicals. It is used in dust removal gear, hydraulic pipes, and anti-corrosion parts. It fights moisture and heat well.

Stainless Steel Parts: Mining dust removal equipment, Hydraulic piping, Corrosion-resistant components

Aluminum Alloy in Mining Machinery

Aluminum alloys are used in mining machines for lightweight parts and heat sinks. They are made using casting, forging, extrusion, and machining.

Forged Aluminum Alloys

Forged aluminum alloys make suspension arms, wheel hubs, and brackets for high-performance mining machines. They lower weight while keeping strength and fatigue resistance.

Forged Aluminum Alloys Parts: Suspension arms, Wheel hubs, Brackets

Aluminum-Silicon Alloys

These alloys are die-cast into motor housings, pump bodies, radiators, and control box housings. They offer excellent heat transfer.

Aluminum-Silicon Alloys Parts: Motor housings, Hydraulic pump bodies, Radiators, Control box housings

Aluminum-Magnesium Alloys

These alloys are extruded or welded into transportation equipment housings, light brackets, and protective covers. They strongly resist rust.

Aluminum-Magnesium Alloys Parts: Transportation equipment housings, Lightweight brackets, Protective covers

High-Strength Aluminum Alloys

These alloys are machined into load-bearing beams, connectors, and power components. They are lighter than steel but can handle much heavier loads.

High-Strength Aluminum Alloys Parts: Load-bearing beams, Connectors, Power components

Other Metal Alloys in Mining Machinery

Special metals are used in mining machines for parts that fight wear, high heat, or need conductivity. High performance comes from casting, forging, or machining these alloys.

Copper and Copper Alloys

These alloys ensure good conductivity and lubrication. They are used in motor windings, busbars, slip rings, and wear-resistant bushings.

Bronze

Bronze fights wear well. It makes worm gears, bushings, and plain bearings. This works well in slow-speed, heavy-load situations.

Brass

Brass is easy to machine. It is often used for hydraulic fittings, valve bodies, and fasteners. It resists rust and is simple to assemble.

Nickel and Nickel Alloys

These alloys resist heat and rust. They are used in gas-driven gear, rust-proof pump bodies, and high-temperature mining parts.

Titanium Alloys

Titanium alloys are light and fight rust. They are used in high-end mining vehicle parts and special mining equipment. This helps to make the service life longer.

How To Customize Mining Metallurgical Parts

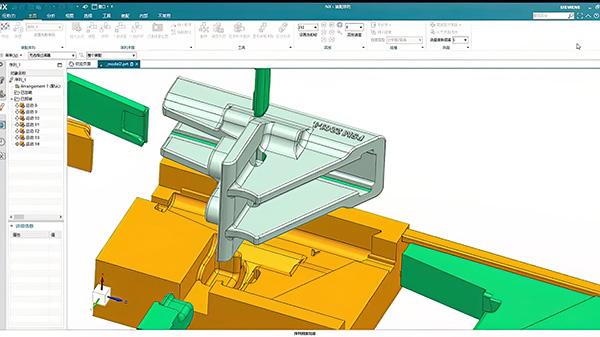

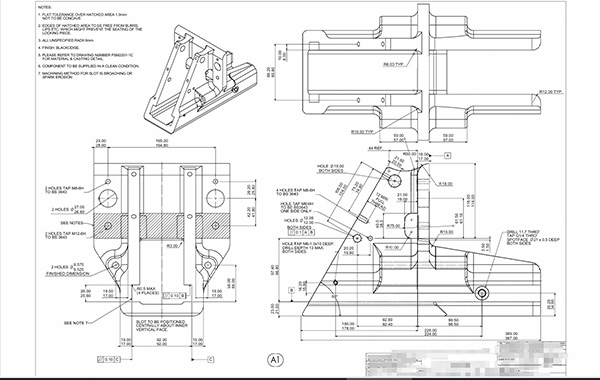

3D Drawings

Processing Drawing

Sample

1. Provide Design Documents or Samples

2. Confirm Material, Process, and Performance

3. Make Production Molds and Samples

4. Comprehensive Sample Inspection

5. Mass Production

6. Post-Production Parts Multiple Quality Inspections

Custom Processing of Mining Metallurgical Parts

Casting in Mining and Metallurgy

The casting process makes parts with complex shapes and large sizes very well. This includes crusher housings, furnace components, and other mining machine parts. Casting is best for making structural parts that meet the specific needs of the mining and metallurgical industries.

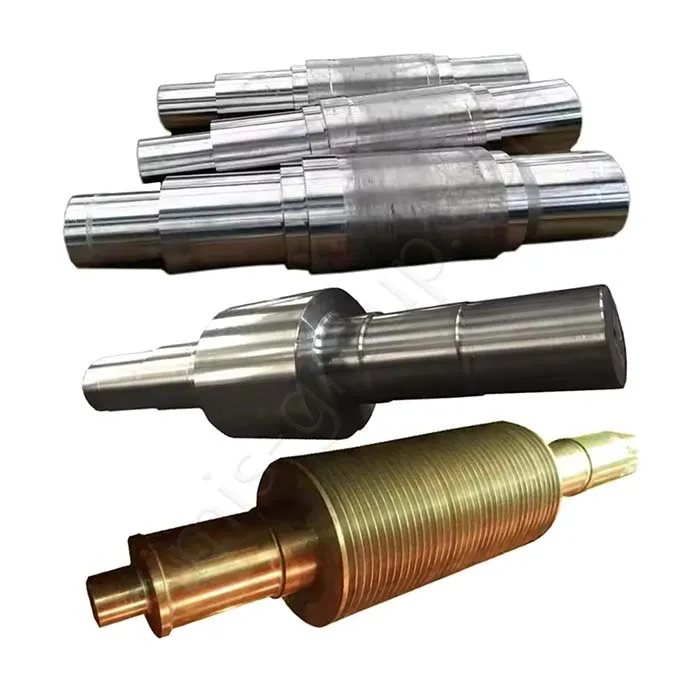

Forging in Mining and Metallurgy

Forging uses compression to shape metal. This makes the material stronger and tougher. In mining and metallurgy, forging makes durable parts like shafts, gears, and heavy equipment components. These parts must handle extreme pressure and wear in machines like crushers, mills, and excavators.

Heat Treatment

Heat treatment involves heating and cooling metals to change their properties. In mining and metallurgy, it is often used to make key parts harder, more wear-resistant, and stronger against fatigue. This includes parts like crusher jaws and mill liners. This process makes these components much more durable in tough environments.

Machining

Machining removes material using cutting tools. This creates precise shapes and sizes. In mining and metallurgy, machining makes high-precision parts. This includes pump components, conveyor rollers, and special tools. These parts need exact tolerances to work correctly and efficiently.

Sheet Metal Fabrication

Sheet metal fabrication cuts, bends, and welds metal sheets to make structural parts. In mining and metallurgy, it creates items like equipment housings, protective covers, and structural frames. These parts are light yet durable. They provide protection and structural integrity in harsh working conditions.

Surface Treatment

Surface treatment includes processes like coating, electroplating, and anodizing. These treatments make material surfaces better. They improve rust and wear resistance. In mining and metallurgy, surface treatment is used on parts like crusher liners and grinding media. This makes them last longer and lowers maintenance needs. It ensures reliable work in highly abrasive environments.