Custom Metal Parts For Agricultural Machinery

Custom metal parts greatly boost the performance and durability of farm equipment. Common custom parts include gears, shafts, plows, harrow blades, and structural supports. These parts can be tailored for specific machines, such as tractors and harvesters. They must handle heavy loads, fight wear and rust, and withstand harsh outdoor conditions. Custom design ensures these metal parts meet exact performance needs. This helps to improve efficiency, cut downtime, and lower maintenance costs on the farm. Manufacturing these parts often uses processes like casting, forging, machining, and heat treatment to make the materials stronger.

Agricultural Machinery Parts Classification

1. Transmission System

The transmission system is vital for moving engine power to the working parts of farm machines. Castings are common for making complex housings and structural parts, such as the gearbox housing, clutch housing, and sprocket seat. Casting provides good stability and is efficient to produce.

Forgings are used for high-strength parts that handle high power and dynamic loads. These include gears, transmission shafts, universal joints, and sprockets. Forging ensures the system has the needed reliability, precision, and durability.

Castings: Gearbox housing, Clutch housing, Sprocket seat

Forgings: Gear, Transmission shaft, Universal joint, Sprocket

2. Working Components

The working components—like tools for tilling and harvesting—face high stress and wear on the farm. Castings are perfect for making large, complex shapes like plow bodies, harrow blades, and cultivator tines. Casting also gives good wear resistance.

Forgings are used for cutting tools and other parts that get hit hard. These include cutting blades, chisels, and tiller tines. Forging gives superior strength and durability. This ensures long-term work in harsh field conditions.

Castings: Plow bodies, Harrow blades, Cultivator tines

Forgings: Cutting blades, Chisels, Tiller tines

3. Frame and Structural Components

The frame and structural components hold the entire machine and keep it stable while working. Castings are often used for parts like the machine base, chassis, and support brackets. Casting is ideal for complex shapes and cost-effective, large-scale production.

Forgings are used for high-strength parts that must resist bending. These include reinforced arms, structural beams, and axles. Forging ensures the necessary stability and resists deformation under heavy loads.

Castings: Machine base, Chassis, Support brackets

Forgings: Reinforced arms, Structural beams, Axles

4. Hydraulic System Components

Hydraulic systems are vital for farm machinery. They control attachments and power different tools. Castings are used to make complex housings, like the hydraulic pump housing, valve body, and oil tank. These parts need to be precise and durable.

Forged components handle high pressure and need to last a long time. These include hydraulic pistons, hydraulic rods, and connecting rods. Forging ensures they have the strength and longevity needed for tough work.

Castings: Hydraulic pump housing, Valve body, Oil tank

Forgings: Hydraulic piston, Hydraulic rod, Connecting rod

5. Chassis and Wheel Systems

The chassis and wheel systems carry the machine's weight. They allow it to move over all kinds of land. Castings are used for making large components, such as wheels, wheel hubs, and suspension parts. Casting offers durability and is easy to produce.

Forged parts go into critical load-bearing spots. These include axles, wheel shafts, and connecting rods. Forging ensures the system has the high strength and long-term reliability needed for movement.

Castings: Wheels, Wheel hubs, Suspension components

Forgings: Axles, Wheel shafts, Connecting rods

6. Powertrain and Drive Components

Powertrain and drive components are vital for moving power from the engine to the wheels or other working parts. Castings are used for housing parts that enclose the shafts and gears, such as the drive housing, gearbox housing, and differential case.

Forgings are used for high-strength components that must handle high power and dynamic stress. These include crankshafts, drive shafts, gears, and differential gears. Forging ensures the machinery runs efficiently.

Castings: Drive housing, Gearbox housing, Differential case

Forgings: Crankshaft, Drive shaft, Gears, Differential gears

7. Steering and Control Systems

Steering and control systems are vital for moving farm machinery efficiently. Castings create detailed components like the steering gear housing, control levers, and steering column. Casting makes production easy and ensures precision.

Forgings are used for parts that handle heavy loads and move often. These include the steering shaft, linkages, and ball joints. Forging ensures smooth, reliable control for the person driving the machine.

Castings: Steering gear housing, Control levers, Steering column

Forgings: Steering shaft, Linkages, Ball joints

Available Materials For Agricultural Machinery Parts

Cast Iron in Agricultural Machinery

In farm machines, cast iron and its types are used to make many parts. We use methods like sand casting, lost foam casting, and heat treatment.

Gray Cast Iron:

Features: Great at absorbing vibrations.

Uses: Found in engine blocks, gearbox housings, and brake discs. It cuts down on vibration and keeps the machine stable during work.

Ductile Iron:

Features: Very high strength and toughness.

Uses: Suitable for wheel hubs, bogie parts, gears, and bearing seats. It handles heavy impact and fatigue loads well.

Alloy Cast Iron:

Features: Fights wear and heat well.

Uses: Used in parts like tillage blade shafts, grinder bushings, and high-friction components. Special alloying or heat treatment can make some parts even stronger after casting or machining.

Steel in Agricultural Machinery

In farm machinery, steel is used for making many load-bearing parts. We use forging, casting, heat treatment, and precision machining to create them.

Carbon Steel:

Features: Offers high strength and toughness.

Uses: Forged into impact-bearing parts like drive shafts, connecting rods, wheel axles, and tiller blade carriers.

Low-Alloy Steel:

Features: Superior resistance to wear and fatigue.

Uses: Forged for gears, hydraulic pump housings, and high-stress connectors.

Cast Steel:

Features: Excellent ability to be formed into complex shapes.

Uses: Cast for hydraulic cylinders, transmission housings, and large chassis parts. Casting ensures precise size and good strength.

High-Manganese Steel:

Features: Highly resistant to wear and impact.

Uses: Cast and heat-treated for tillage blades, track shoes, roller shafts, and crusher rollers. It adapts well to heavy loads and impacts.

Aluminum Alloys in Agricultural Machinery

In farm machines, aluminum alloys are used to create lighter parts. We use processes like die casting, sand casting, extrusion, and machining.

High-Strength Aluminum Alloys:

Features: They are light but very strong.

Uses: Used for cab skins, engine hoods, and lightweight brackets. This cuts the machine's total weight while keeping its structure strong.

Corrosion-Resistant Aluminum Alloys:

Features: They form a dense, protective layer on the surface that fights rust.

Uses: Made into hydraulic guides, decorative parts, and fasteners. This boosts the part's durability.

Easy-to-Machine Aluminum Alloys:

Features: Easy to machine and weld.

Uses: Suitable for instrument brackets, protective covers, and electrical equipment housings. Heat treatment can be used to make them tougher and stronger.

Other Metal Alloys

Besides common cast iron, steel, and aluminum, farm machines use specialty metals. These include copper, titanium, and magnesium. These alloys are picked for their ability to fight heat, resist rust, or provide high strength.

Copper and Copper Alloys:

Features: They resist wear and conduct electricity very well.

Uses: Used in electrical components, bearing bushings, and hydraulic slides. We make these using casting or machining.

Titanium Alloys:

Features: They are very strong, light, and resist rust.

Uses: Suitable for high-performance springs, fasteners, and structural brackets. We make these through forging or machining.

Magnesium Alloys:

Features: They are very light and easy to machine.

Uses: Used for cab skins, brackets, and instrument panels. We use die casting and machining to make them. This helps lower the machine's total weight.

How To Customize Agricultural Machinery Parts

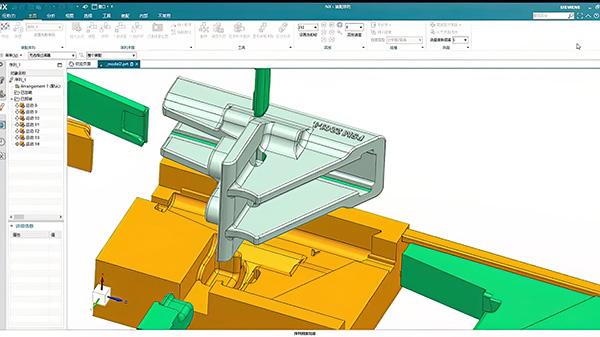

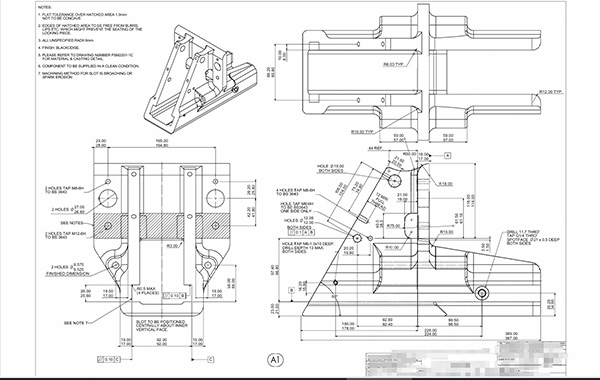

3D Drawings

Processing Drawings

Sample

1. Design Review and Initial Samples

2. Confirm Details: Material, Process, and Performance

3. Make Molds and Samples

4. Comprehensive Sample Inspection

5. Mass Production

6. Post-Production Quality Checks

Custom Processing Of Agricultural Machinery Parts

Casting Agricultural Machinery Parts

In the farm machinery industry, casting makes parts with complex shapes and large sizes. This includes engine blocks, gearbox housings, and pump housings. Casting is ideal for making large parts that need high strength and durability. This ensures the parts can handle the heavy loads, vibrations, and harsh conditions common on the farm.

Forging Agricultural Machinery Parts

In the farm machinery industry, forging creates high-strength components. These include axles, gears, shafts, and structural parts. Forging boosts the mechanical strength and reliability of equipment. This is key for machines like harvesters, plows, and tractors that work under heavy loads and continuous use.

Heat Treatment for Agricultural Machinery Parts

In the making of farm machinery parts, heat treatment is used on transmission components. This includes parts like gears, shafts, and bearings. The process boosts the wear resistance and toughness of high-friction, high-stress parts. This helps to extend the life of mechanical parts and cuts down on maintenance needs.

Machining for Agricultural Machinery Parts

In the farm machinery parts industry, machining creates highly precise components. These include engine parts, hydraulic accessories, and transmission parts. Machining ensures that parts fit together perfectly with the correct clearance. This boosts the performance, efficiency, and service life of farm machines like tractors and harvesters.

Sheet Metal Fabrication for Agricultural Machinery Parts

In the farm machinery parts industry, sheet metal fabrication makes many components. These include the chassis, frames, guards, and body panels. This method creates parts that are lightweight but very strong. It boosts the machine's overall structure and safety. Plus, sheet metal fabrication can quickly produce large numbers of parts with different designs.

Surface Treatment for Agricultural Machinery Parts

In the making of farm machinery parts, surface treatment is key. We apply processes like coating, electroplating, and anodizing to parts such as plow blades, harvester knives, and frames. This boosts corrosion resistance, wear resistance, and durability. The treatment protects parts from harsh conditions like moisture, dirt, and chemicals. This ensures reliable performance and extends the service life of key farm components.