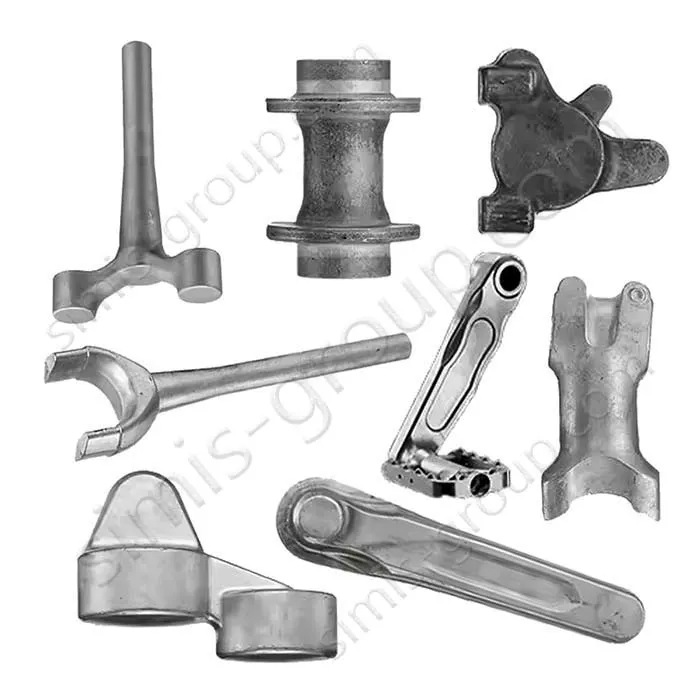

Custom Shock Mount Bracket Manufacturer

Shock Mount Bracket

China Simis Company specializes as an OEM custom manufacturer of Safety-Critical Shock Mount Brackets. These components are the direct interface between the frame/axle and the suspension system, subjecting them to continuous high-frequency cyclical fatigue loads and severe impact stress from rough terrain. Failure in a shock mount bracket compromises vehicle stability and safety.

We utilize Precision Forging for maximum strength and fatigue life in high-stress steel and aluminum applications (e.g., trucks, MTB). Specialized Casting (Sand, Investment, Gravity Permanent Mold Casting) is employed for high-volume, cost-effective structural components using Ductile Iron and Cast Steel. Our primary focus is on engineering for superior fatigue life, guaranteed toughness, and precise mounting bore alignment.

What are the manufacturing processes for Shock Mount Bracket?

The process selection is crucial for achieving the density, grain structure, and material soundness required to prevent fatigue failure under stress cycling. Each process is matched to the specific load and performance demands of the shock mount bracket application.

| Manufacturing Process | Component Focus | Material Focus | Key Advantage for Shock Mount Performance |

| Precision Closed Die Forging | High-Stress Links, Axle/Frame Mounting Lugs. | Alloy Steel, High-Strength Aluminum Alloy. | Maximum Fatigue Life and Toughness. Forging creates optimal grain flow, essential for withstanding millions of stress cycles without fracture initiation. |

| Sand Casting / Shell Mold Casting | Heavy-Duty Truck Axle Housings, Frame Mounts. | Ductile Iron (A 536), Carbon Steel. | High Structural Integrity. Reliable method for critical structural parts requiring excellent internal soundness for fatigue resistance. |

| Lost Foam Casting (LFC) | Complex Geometry Brackets, Integrated Mounts. | Ductile Iron, Cast Steel. | High Cost-Effectiveness and Near-Net Shape. Suitable for intricate bracket designs, minimizing subsequent machining and material waste. |

| Gravity Permanent Mold Casting (GDC) | High-Volume Aluminum Brackets, Motorcycle Components. | Aluminum Alloy (6061). | Provides better density and mechanical properties for Al than sand casting, suitable for lightweight, mid-stress applications. |

| Investment Casting | Small, Precision Stainless Steel Links/Mounts. | Stainless Steel (304, 316), Alloy Steel. | High Precision and Corrosion Resistance. Suitable for marine or complex mounting geometries requiring tight tolerances. |

| Precision CNC Machining | Bore Alignment, Mounting Surfaces, Welding Bosses. | All Materials. | Critical for Suspension Geometry. Ensures precise coaxiality of shock mounting bores and correct positioning for welding/bolting. |

What Materials Ensure Shock Mount Bracket Fatigue Resistance, Impact Toughness, and Weldability?

Material selection must account for the primary load type (weight/fatigue) and the harsh environment of service (impact/corrosion). Each material grade is selected to meet the exact performance requirements of the target application.

| Material Type | Primary Performance Requirement | Typical Shock Mount Application & Service |

| Alloy Steel (AISI 4140, 8620) | Maximum Fatigue Strength, High Toughness (After Forging/HT). | Forged Brackets for heavy-duty trucks, trailers, and mining equipment. |

| Ductile Iron (ASTM A 536) | Excellent Shock Absorption, High Strength-to-Cost Ratio. | Sand/shell mold/LFC Cast Brackets for agricultural machinery, general construction equipment, and cost-effective heavy-duty mounts. |

| Carbon Steel (AISI 1045) | Good Weldability, High Structural Strength. | Brackets designed for direct welding onto frame rails and axle tubes. |

| Aluminum Alloy (6061, 7075) | Lightweight, Corrosion Resistance (Anodizing), High Fatigue Life. | Forged/GDC mounts for high-performance motorcycles and mountain bikes (MTB). |

| Stainless Steel (304, 316) | Corrosion Resistance in Marine/Salinity Environments. | Mounts for marine trailers or equipment operating in petrochemical/salt-laden areas. |

What Quality Assurance and Certification Ensure Shock Mount Bracket Structural Fatigue Performance?

QA focuses intensely on internal material soundness and dimensional precision to guarantee the bracket's fatigue life and functional alignment. All inspection and testing protocols comply with industry standards for safety-critical suspension components.

·Cyclical Fatigue Testing:

Components are tested under simulated road loads to verify the structural design and material can withstand the specified millions of high-frequency stress cycles without initiating fatigue cracks.

·Impact and Fracture Toughness Testing:

Charpy V-Notch Testing is performed on steels and irons to confirm the component's ability to absorb energy and resist brittle fracture during sudden impacts (essential for off-road/mining).

·Weld Integrity Checks (NDT):

For components intended for welding, MPI (Magnetic Particle Inspection) verifies the surface integrity around the critical welding zones, and UT (Ultrasonic Testing) checks internal soundness.

·Bore and Surface Alignment:

CMM Verification of the coaxiality of the shock mounting bores and the parallelism of the mounting face to ensure correct suspension geometry and prevent shock absorber binding.

What are the applications of custom shock mount brackets?

We classify bracket solutions based on the required load bearing, operating environment, and weight objectives. This categorization ensures that each bracket is engineered to meet the exact performance demands of its intended use.

| Application Category | Primary Load/Environment | Ideal Process/Material Focus | Component Example |

| Heavy-Duty & Mining | High Weight, Extreme Impact, Structural Overload. | Forged Alloy Steel (Maximum Toughness) or Sand/Shell Mold/LFC Cast Ductile Iron. | Truck Axle Mounts, Loader Control Arm Brackets. |

| Performance & MTB | Lightweight, High Fatigue, Complex Geometry. | Forged/GDC Casting Aluminum Alloy (Lightweight/Rigid). | Motorcycle Fork Brackets, MTB Frame Links. |

| Agricultural & Trailer | Moderate Fatigue, High Corrosion Exposure, Cost-Sensitive. | Sand Cast Ductile Iron or Cast/Forged Carbon Steel. | Trailer Axle Mounts, Tillage Equipment Hitch Brackets. |

What Are the Advantages of Simis OEM Custom Shock Mount Bracket Manufacturing?

Simis ensures the certified structural integrity necessary for safety and performance across all suspension mounting applications. Our core advantages are built on process expertise, material science, and precision quality control.

·Fatigue Life Engineering:

We prioritize manufacturing components with optimal grain structure (Forging) and certified material soundness (Casting NDT), providing a guaranteed fatigue life far exceeding minimum service requirements.

·Cost-Effective Complexity:

We utilize Lost Foam Casting (LFC) for complex structural shapes in Ductile Iron, optimizing cost while still maintaining required toughness and structural density.

·Precision Geometry Guarantee:

Our advanced CNC machining and CMM inspection ensure the perfect coaxiality and alignment of mounting bores, which is critical for smooth suspension travel and preventing premature wear.

·Process Versatility for Weight:

We offer flexible solutions, utilizing Forged Aluminum for maximum strength-to-weight in performance sectors, and robust Ductile Iron Casting for cost-effective toughness in heavy industry.

How to Get a Quote for Custom Shock Mount Bracket Manufacturing Services?

China Simis Company is your expert global partner for custom forging and casting Shock Mount Brackets, engineered for safety-critical structural fatigue life, high impact resistance, and precise suspension alignment. To receive a detailed and accurate quotation for your custom shock mount bracket project, please provide the following technical documents and specifications to our professional engineering team:

2D technical drawings or 3D CAD models with complete dimensional tolerances (including bore coaxiality, mounting face parallelism, and welding boss positions)

Detailed application information (e.g., Heavy-Duty Truck Frame Mount, MTB Swingarm Link, Marine Trailer Axle Mount)

Expected load conditions (static weight, dynamic impact G-forces, cyclical fatigue cycle requirements)

Target material grade and finish requirements (e.g., Ductile Iron ASTM A536, Aluminum Alloy 6061-T6, Stainless Steel 316 with Passivation)

Production volume and delivery timeline expectations

Any specific industry certification requirements (e.g., ISO, SAE standards for automotive suspension components)

Our engineers will conduct a comprehensive structural feasibility analysis, offer design optimization recommendations to enhance fatigue resistance and impact toughness, and deliver a full quotation package covering unit pricing, tooling costs, production lead time, quality control protocols, and global delivery terms.