Machining Factory for OEM Custom Manufacturing

Machining Workshop Introduction

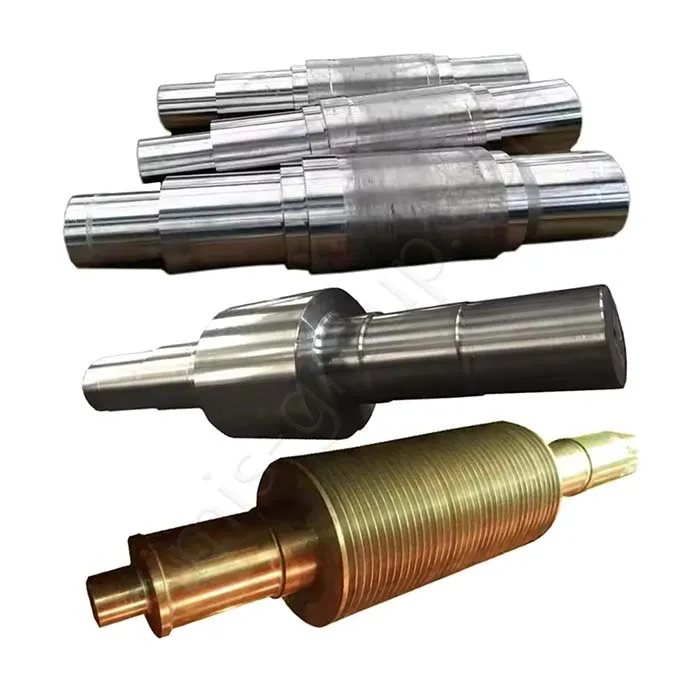

The SIMIS Machining Factory specializes in high-precision machining and making critical parts. We use advanced CNC centers, automated lines, and a full inspection lab. We provide precision machining for castings, forgings, sheet metal, and bar-stock components.

SIMIS serves many sectors: automotive, construction, hydraulics, energy, railway, marine, aerospace, and general machinery. We offer solutions that are highly accurate, reliable, and consistent.

CNC Turning Centers: Machining diameter Ø10–Ø800 mm, length up to 1,500 mm

Vertical Machining Centers: Travel X: 1,000 mm / Y: 600 mm / Z: 600 mm

Horizontal Machining Centers: 4-axis, pallet size 630 × 630 mm

Five-axis Machining Centers: Complex surface parts, accuracy ±0.005 mm

Grinding and Honing Machines: Roundness ≤ 0.002 mm; surface roughness Ra ≤ 0.4 μm

Gear Machining Equipment: Module 1–10, max diameter Ø500 mm

Deep Hole Drilling and Boring Machines: Hole Ø5–100 mm; depth ratio up to 1:20

Multi-axis and Five-axis Machining: enables high-precision processing of complex 3D surfaces and geometries

OEM Custom Machining Part

Machining Process for Custom Metal Parts

Machining process overview

Machining technology is the process of cutting, forming, grinding and other operations on metals through mechanical equipment to achieve precision processing and shape changes of parts. Common machining methods include turning, milling, drilling, grinding, boring, etc. Each method can be selected and used according to different workpiece characteristics and design requirements. The main purpose of machining technology is to improve the dimensional accuracy, surface quality and shape complexity of parts, and it is widely used in the fields of automobiles, aviation, machinery, electronics, etc.

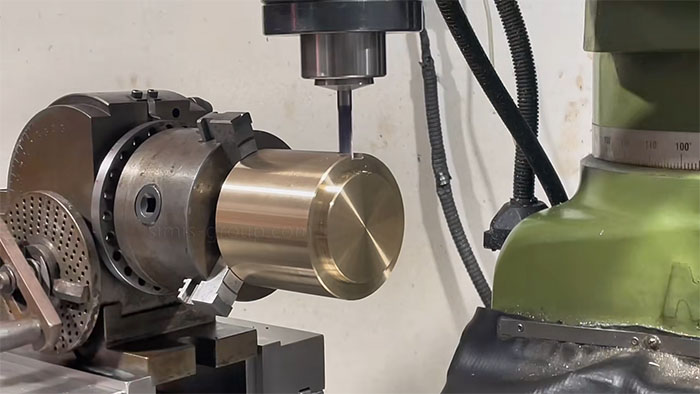

1. Turning

Turning is the process of fixing a workpiece on a rotating workpiece holding device through a lathe, and then cutting its surface with a tool.

Turning is mainly used to process common shapes such as outer circles, inner holes, threads, and grooves. It can quickly remove materials and achieve high processing accuracy.

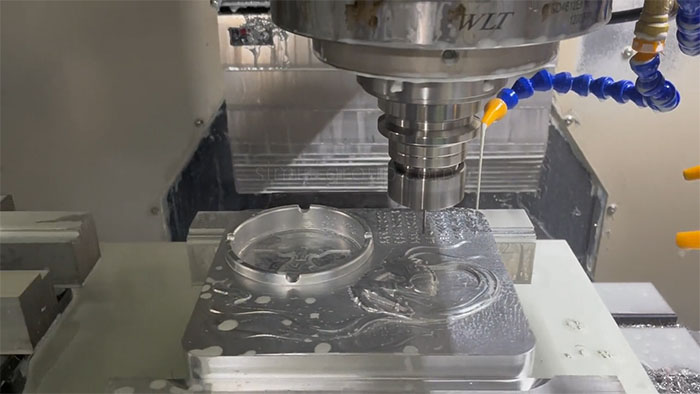

2. Milling

Milling is a process of cutting the surface of a workpiece using a milling machine and a rotating tool. According to different cutting methods, milling can be divided into plane milling, forming milling, end milling, etc.

Milling is suitable for workpieces of various materials and shapes, and can achieve a variety of cutting methods. It is particularly suitable for processing complex part shapes and surfaces.

3. Drilling

Drilling is the process of drilling holes in a workpiece using a rotating drill bit through a drilling machine or a CNC drilling machine. Drilling is widely used in the processing of metal materials and is often used to make holes. Common types of drilling include:

straight holes, blind holes, through holes, reaming holes and boring holes.

Drilling is usually used to process circular or linear holes, and the depth and accuracy requirements of the holes can be met by selecting different drill bits.

4. Grinding

Grinding is a processing method that uses a high-speed rotating grinding wheel to cut the surface of the workpiece. Grinding is mainly used to improve the surface quality and processing accuracy of parts. Common forms of grinding include: surface grinding, external cylindrical grinding, internal cylindrical grinding, and centerless grinding.

Grinding processes are usually used in the finishing stage of metal parts to achieve higher dimensional accuracy and surface finish.

5. Boring

Boring is a process of finishing the inner hole of a workpiece using a tool on a boring machine. Unlike drilling, boring is a precision machining process using a larger tool, which can remove a small amount of material and improve the dimensional accuracy and surface quality of the hole. Common types of boring include: internal boring and end boring.

Boring is usually used for finishing of processed holes to improve the dimensional accuracy and surface quality of the holes, and is especially suitable for processing large holes.

6. Laser Cutting

Laser cutting is a method of using a high-energy laser beam to accurately cut materials. It has the advantages of high cutting accuracy, small heat-affected zone, and fast cutting speed.

7. Wire EDM

Wire cutting is a cutting method based on the principle of electric sparks. It uses thin copper wires as electrodes to perform precise cutting on the workpiece through electric sparks. This method is suitable for processing complex shapes and high-hardness materials, and is often used in mold manufacturing, precision parts processing, etc.

Available Materials for Machining Applications

What metal parts can machining?

Machining is applicable to a variety of metal materials, including cast iron, carbon steel, alloy steel, stainless steel, aluminum alloy, copper alloy, titanium alloy, tool steel, etc.Different metal materials can meet the requirements of processing accuracy and performance in different fields by selecting appropriate machining methods.

1. Cast Iron

·Gray (Grey) Iron

·Ductile Iron

·Malleable cast iron

·Alloy cast iron:High chromium alloy cast iron, High nickel alloy cast iron, Silicon alloy cast iron, Aluminum alloy cast iron, …

2. Steel

·Carbon Steel: Mild Steel, Medium Carbon Steel, High Carbon Steel,

·Alloy Steel: Low alloy steel, High alloy steel,

·Stainless steel: Austenitic stainless steel, Ferritic stainless steel, Martensitic stainless steel, Duplex stainless steel, ...

·Tool Steel: High speed tool steel, Cold work tool steel, Hot work tool steel, ...

3. Aluminum Alloys

·Aluminum-Silicon Alloys

·Aluminum-Magnesium Alloys

·Aluminum-Zinc Alloys

·…

4. Other Metal Alloys

·Brass

·Bronze

·Nickel alloys

·Titanium alloys

·…