Manufacturing Capabilities of Aluminum Casting Foundry

Aluminum Sand Casting

Aluminum sand casting uses sand molds to pour liquid aluminum alloys (such as A356, A380, etc.) into shape. It has low production costs, short delivery cycles, economical mold costs, and extremely high design freedom and dimensional load-bearing capacity. It is suitable for producing lightweight parts with large size, complex shape, or large production volume.

Cast Weight Range: 0.1 kg – 500 kg

Maximum Dimensions: up to 3 m

Dimensional Tolerance Grade: CT9 to CT12 Grade

Surface Roughness (Ra): Ra 6.3 to 25.0 μm

Minimum Wall Thickness: 4 mm to 8 mm

Aluminum Die Casting

Aluminum die casting is a cold chamber die casting process in which liquid aluminum alloy is injected into a precision metal mold cavity under extremely high pressure. It has extremely high production efficiency, excellent dimensional accuracy and excellent surface finish, and is suitable for large-scale, high-volume production of thin-walled, structurally complex lightweight aluminum alloy castings.

Cast Weight Range: 0.02 kg – 10 kg

Maximum Dimensions: 0.6 m × 0.5 m × 0.5 m

Dimensional Tolerance Grade: CT4 to CT6

Surface Roughness (Ra): Ra 0.8 to 3.2 μm

Minimum Wall Thickness: 0.8 mm to 4.0 mm

Aluminum Gravity Casting

Aluminum gravity permanent mold casting uses gravity to pour liquid aluminum alloy into a reusable metal mold and cools and solidifies it in a specific direction. It has a long mold life, stable product quality, low internal porosity, and allows for heat treatment such as T6. It is suitable for mass production of complex aluminum alloy castings with high requirements for strength and airtightness.

Cast Weight Range: 0.5 kg – 50 kg

Max Dimensions: 1.0 m × 0.8 m × 0.5 m

Dimensional Tolerance Grade: CT7 to CT9 Grade

Surface Roughness (Ra): Ra 6.3 to 12.5 μm

Minimum Wall Thickness: 4 mm to 6 mm

Heat Treatment

Heat treatment of cast aluminum parts aims to optimize their mechanical properties, especially strength and hardness. This is achieved through solution treatment and aging processes that precipitate strengthening phases in the matrix, significantly improving material properties. SIMIS Aluminum Foundry offers specialized T6 heat treatment for heat-treatable aluminum alloys (such as A356 and A357) to meet stringent requirements for lightweight and high-strength parts.

T6 Heat Treatment: Relieve internal stress; maximize strength and hardness; increase yield strength.

Solution Treatment: Homogenize alloying elements; prepare for aging.

Artificial Aging: Precipitate strengthening phases; significantly boost mechanical strength.

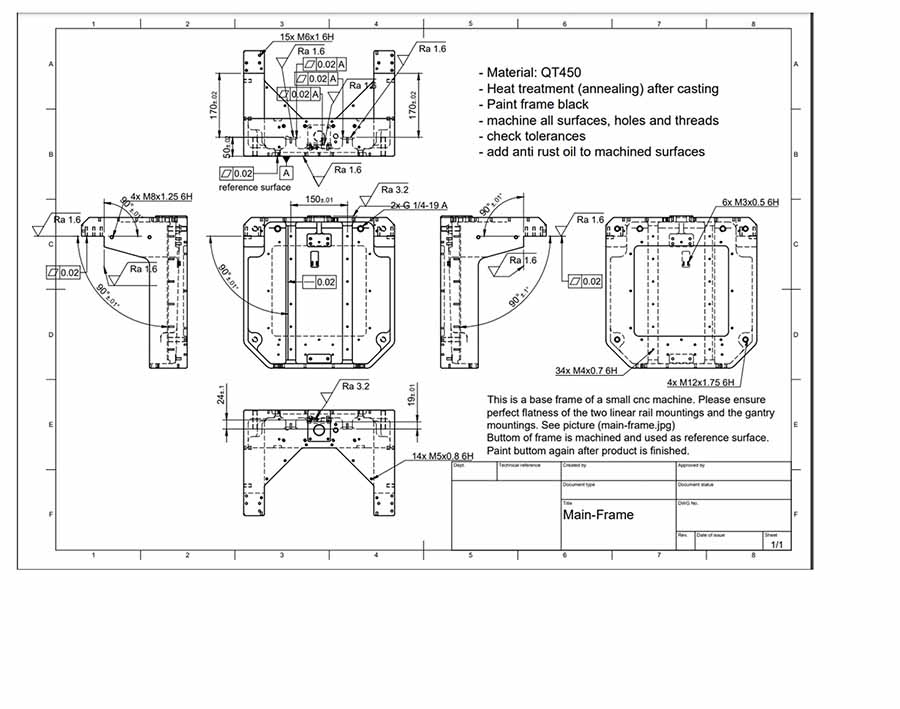

Machining

Machining is essential for achieving lightweight, high-precision fit, and strict tolerances in cast aluminum parts. SIMIS Aluminum Foundry is equipped with high-speed, high-precision CNC equipment, capable of efficiently handling all drilling, tapping, milling, boring, and precision turning of cast aluminum parts, ensuring the critical dimensional accuracy and geometric requirements of complex aluminum alloy casting components.

Machining Tolerance: IT6 to IT4 Grade

Surface Finish (Ra): Ra 1.6 to 0.2 μm

Min Tool Diameter: 0.3 mm

Inspection Capability: CMM measurement accuracy up to ±0.003mm

Surface Treatment

Surface treatment aims to improve the corrosion resistance, wear resistance, and aesthetics of cast aluminum parts. Due to the unique chemical properties of aluminum, it primarily involves forming or covering a stable, dense oxide or coating. SIMIS Aluminum Foundry offers a variety of surface treatment processes to meet the stringent requirements of its customers for aluminum casting components.

Anodizing: Long-term anti-corrosion; aesthetic coloring; enhances hardness.

Hard Anodizing: Ultimate surface hardness and wear resistance.

Powder Coating/Painting: Excellent weather resistance; provides color and aesthetics.

Electrophoresis (E-coating): Uniform anti-corrosion coverage; ideal for complex cavities.

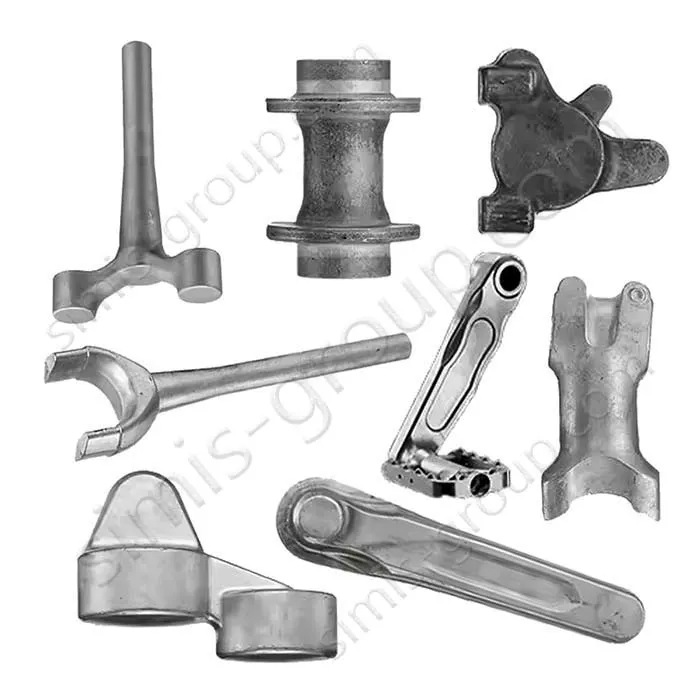

OEM Custom Cast Aluminum Parts by Aluminum Foundry

Cast Aluminum Materials for Custom Casting Applications

Aluminum-Silicon Alloy Casting

Aluminum-Silicon alloys make light, complex parts. They offer great casting ability and a strong ratio of strength to weight. Adding silicon to aluminum makes the liquid metal flow better, lowers its melting point, and cuts down on shrinkage. Al-Si alloys are the most common cast aluminum materials across all industries.

Al-Si Alloy Castings from Simis Aluminum Foundry:

Engine cylinder heads, intake manifolds, and pistons;

Transmission cases and housings;

Pump bodies and impellers;

Building fittings;

Electronic boxes and heat sinks;

Car wheels and structure parts.

Simis can cast Al-Si alloy types:

Hypoeutectic Alloys (Silicon 5% - 10%): Structural car parts (cylinder heads), aerospace parts, and high-strength machine parts.

Eutectic Alloys (Silicon around 11% - 13%): Complex, thin-walled castings. They are great for parts needing a tight seal, like pump and valve bodies.

Hypereutectic Alloys (Silicon over 14%): Engine pistons, cylinder liners, and brake rotors. These parts need high wear resistance and stability in hot conditions.

Aluminum-Copper Alloy Casting

Aluminum-Copper alloys produce high-strength components. These alloys prioritize high strength over ease of casting, positioning them among the strongest cast aluminum materials available. They are highly responsive to heat treatment, which is utilized to optimize their mechanical properties for aerospace and other demanding, high-performance applications.

Al-Cu Alloy Castings from Simis Aluminum Foundry:

Aircraft structural fittings and brackets;

High-performance car suspension parts;

Cylinder heads for air-cooled engines;

Strong robotic arms and machine parts.

Simis can cast Al-Cu alloy types:

Binary Al-Cu Alloys: General high-strength parts, structural components, and parts needing good toughness.

Al-Cu with Silicon Added: Complex, high-strength parts, like cylinder heads and crankcases.

Highest-Strength Al-Cu Alloys (with Mg, Mn, Cd added): Critical aerospace parts. Best for high strength-to-weight ratio jobs.

Aluminum-Magnesium Alloy Casting

Aluminum-Magnesium alloys provide high corrosion resistance, significant ductility, and an excellent surface finish. These properties make them suitable for extensive use in marine, offshore, and chemical processing environments.

Al-Mg Alloy Castings from Simis Aluminum Foundry:

Boat parts and marine hardware;

Gear for chemical plants;

Parts for handling food and drinks;

Building and decorative fittings;

Pressure vessels for corrosive jobs.

Simis can cast Al-Mg alloy types:

Low Magnesium Alloys (Mg 3-5%): General parts needing rust resistance, marine fittings, and food processing gear.

Medium Magnesium Alloys (Mg 5-7%): Structural parts for boats, pump bodies, valve housings, and chemical processing gear.

High Magnesium Alloys (Mg 7-10%): High-strength marine parts, naval architecture, and jobs needing the best rust resistance.

Other Aluminum Alloys Casting

The Simis Aluminum Foundry can cast many other aluminum alloys. These include aluminum-zinc, aluminum-manganese, and aluminum-titanium alloys. They are used for parts that need great high-temperature performance, controlled heat expansion, or a unique mix of features. This meets the needs of special jobs across many industrial fields.

Specialty Castings from Simis Aluminum Foundry:

Pistons and cylinder heads for engines;

Precise systems for optics and instruments;

Bearing sleeves and bushings;

Aerospace parts that need heat stability;

Electronic boxes needing specific heat management.

Simis can cast specialty alloy types:

Al-Sn Bearing Alloys: Engine connecting rod bearings, main bearings, and other high-load sliding parts.

Al-Zn Alloys: Building fittings, decorative parts, and general machine components.

High Iron and Manganese (Heat-Resistant): Car turbo housings, piston crowns, and other parts that work in high heat.

Al-Mn Alloys: Chemical gear, food handling parts, heat exchangers, marine parts, and building components needing good welding traits.

Industries Served by Our Aluminum Casting Foundry

How to Customize Aluminum Castings with Aluminum Foundry

Confirm Manufacturing Requirements for Cast Aluminum Parts

Design Review and Samples

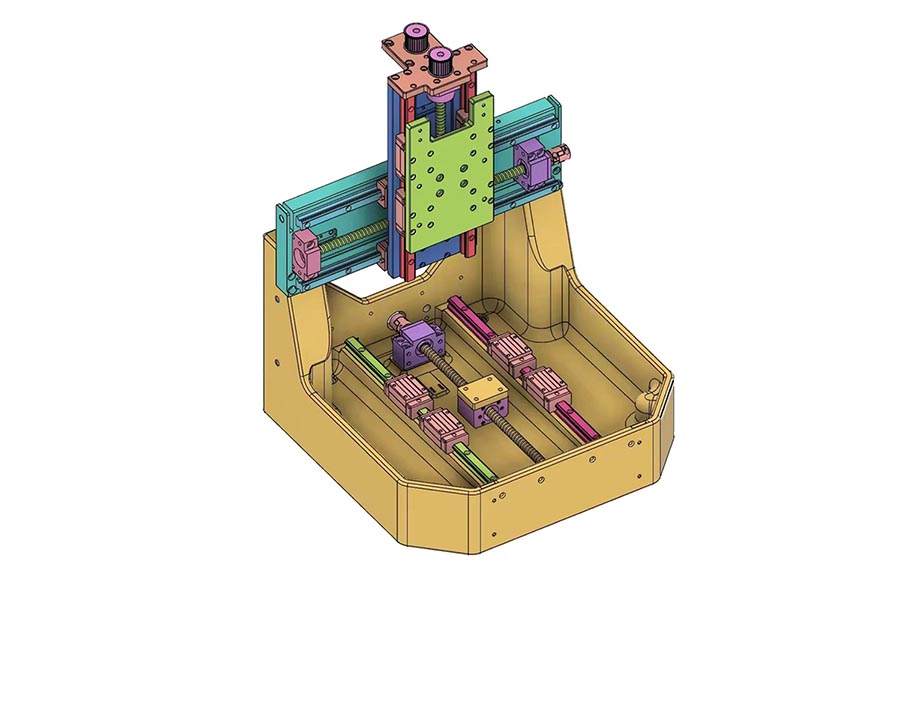

Simis engineers first check the 3D and plane drawings. This makes sure your design is ready for manufacturing. If you have a sample part, we can make the new parts based on that sample.

Define Part Requirements

We confirm what the part needs to do. This includes things like its strength, hardness, wear, and rust resistance. We also set the exact size, tolerance, and finish quality needed.

Confirm Casting Material

Our engineers help you pick the right cast aluminum material. This choice depends on where the part will be used and your technical needs. We give advice based on material cost, strength, and resistance to wear or rust.

Choose the Casting Method

We select the best casting process for your part. We base this choice on your price goal, the part’s shape, its required accuracy, and the material.

Make Molds and Samples

We build the casting molds using your approved drawings or samples. Then, we cast the first batch of samples using the chosen material and process.

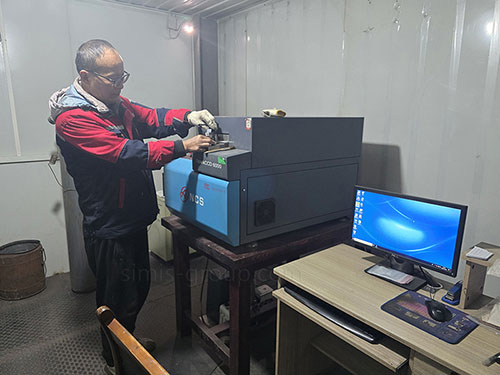

Full Sample Inspection

The finished samples go through a full check. This confirms they meet all design standards and your quality demands. We give you reports covering size, performance, material makeup, and non-destructive testing.

Production and quality control

Mass Production

After you check and approve the sample, we start the mass production plan. We get all the materials ready based on your order. We use the exact same machines and process as we did for the sample. This makes sure every single part we make is the same.

Quality Control During Production

We run tight quality checks while making the parts. We pull parts for checks often during the process. We test their size, look, and strength. This ensures every batch of cast aluminum parts is consistent and meets your needs.

Final Product Quality Inspection

We use multiple inspectors for the final check. They do many tests on the finished product. These tests cover size accuracy, surface quality, and part strength. This step makes sure all cast aluminum parts meet your quality standards.

Packaging and Delivery

We securely package and ship all approved parts. We pick the right packaging to prevent damage during shipping. We also choose the best delivery method (air, sea, or land) to get your parts to you on time.

To order custom parts, please email us your design drawings and 3D models. Our team will review the detailed part parameters and the 3D model to provide you with an accurate quote.