Sheet Metal Fabrication for OEM Custom Manufacturing

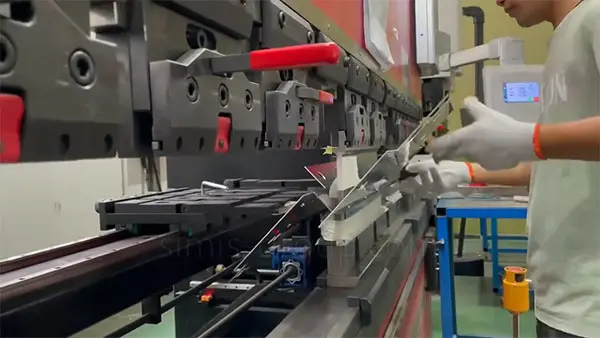

Sheet Metal Fabrication Workshop Overview:

SIMIS Sheet Metal Fabrication Factory specializing in high-precision sheet metal components and complete enclosures. The plant integrates CAD/CAM design, laser cutting, bending, punching, welding, surface treatment, assembly, and inspection, capable of producing thin and medium-thick metal structural parts.

SIMIS serves industries including mechanical equipment, electronics, automation, energy, automotive, and rail transportation, providing high-quality, high-precision, and batch-capable sheet metal solutions for global customers.

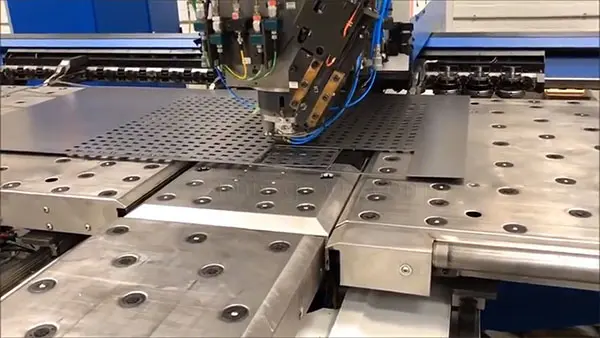

Laser Cutting Machines: Max bed size: 3,000 × 1,500 mm; laser power: 3–6 kW

Plasma Cutting Machines: Plate thickness 2–50 mm

Shearing Machines: Max length 3,000 mm; max thickness ≤ 20 mm

Bending Presses: Max bending length 4,000 mm; max tonnage 400T

Punching and CNC Punching Machines: Max tonnage 160T; automatic feeding & die change

Welding Equipment: CO2 MIG/MAG, TIG, robotic welding lines

Processing Range: Thickness 0.5–50 mm; width ≤ 3,000 mm; length ≤ 6,000 mm

High Precision: CNC laser cutting, bending, and welding ensure tolerances ±0.1 mm

Sheet Metal Fabrication Process for Custom Metal Parts

Sheet Metal Fabrication process overview

Sheet metal fabrication is a series of processing operations on metal sheets (thin plates) to make them into parts of required shapes and sizes for use in electronics, machinery, home appliances, automobiles and other industries to meet different functional and appearance requirements.

1. Cutting

Metal sheets are cut into the required shape or size by mechanical, laser, plasma or water jet.

· Laser cutting

· Plasma cutting

· Water jet cutting

· Shear cutting

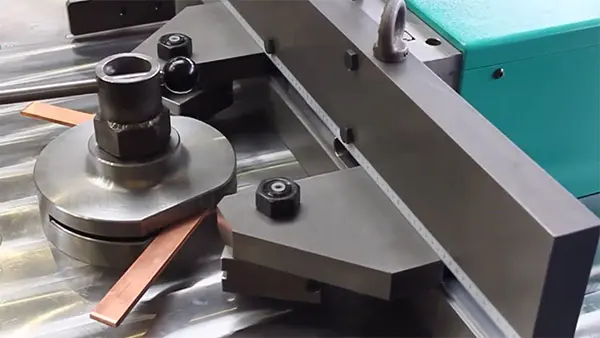

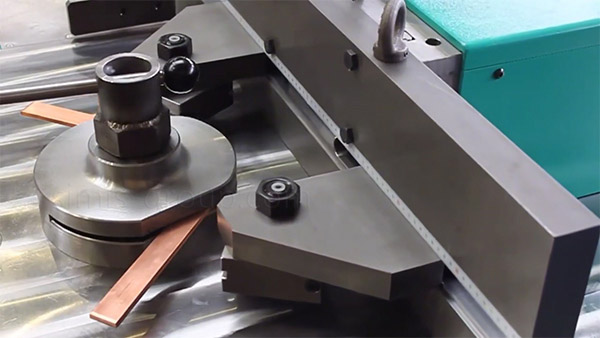

2. Stamping

Use dies and punches to apply pressure to metal sheets to deform them and produce the required shape and holes.

· Punching

· Forming

· Blanking

· Bending

3. Bending

The process of bending metal sheets at a certain angle by a bending machine is widely used in the production of metal structural parts.

· CNC bending

· Manual bending

4. Welding

The metal parts are partially melted by heating, pressurizing or a combination of both to form a strong connection.

TIG welding (TIG welding)

· MIG welding

· Spot welding

· Laser welding

5. Riveting and assembly

The rivets are inserted into the workpiece by mechanical force to connect. Similar to bolt connection, the advantage of riveting is that bolts are not required, which is suitable for use in occasions with high sealing and strength requirements.

· Rivet connection

· Bolt connection

· Welding connection

6. Stretching forming

Sheet metal is stretched into a specific shape through a die, which is often used to manufacture complex curved parts, such as car bodies, home appliance housings, etc.

7. Punching and trimming

Punching and trimming of metal sheets through a punching machine is used to mass produce parts with complex hole shapes or edges.

Available Materials for Sheet Metal Fabrication Applications

Simis Sheet Metal Fabrication Materials

Simis Sheet Metal Fabrication Factory is capable of performing stamping, bending, shearing, welding, and surface finishing on a variety of sheet materials to meet diverse custom needs. Our commonly used materials include Carbon Steel (CRS/HRS), Stainless Steel, Aluminum Alloys, and Galvanized Steel. Sheet metal fabrication utilizes the good formability of these materials to produce parts such as enclosures, cabinets, brackets, and casings that feature light weight, high structural strength, cost efficiency, and design flexibility.

Carbon Steel (Cold Rolled Steel, CRS & Hot Rolled Steel, HRS)

Carbon steel sheets are the most common and economical materials for sheet metal work.

Applications: Suitable for various enclosures, structural brackets, and general machinery components.

Properties: Cold Rolled Steel (CRS): High surface finish and good dimensional accuracy, suitable for parts requiring high-quality surface treatments like powder coating or plating.

Hot Rolled Steel (HRS): Lower cost, suitable for structural components where a good surface finish is not critical and dimensional tolerance is looser.

Common Grades: AISI 1008, 1010, Q235B.

Stainless Steel

Stainless steel sheets offer excellent corrosion resistance, strength, and aesthetics, making them ideal for high-end applications.

Applications: Used in food machinery, medical equipment, outdoor enclosures, and high-corrosion environment components.

Properties: Possesses good weldability and formability, especially austenitic stainless steel (300 series), which does not require additional anti-rust treatment after processing.

Common Grades: ASTM 304 (Most common, good corrosion resistance, easy to fabricate), 316/316L (Enhanced resistance to acids and pitting with added molybdenum), 430 (Magnetic, lower cost alternative).

Aluminum Alloy

Aluminum alloy sheets are preferred for lightweight design and thermal applications due to their high strength-to-weight ratio and excellent thermal conductivity.

Applications: Widely used in aerospace, automotive parts, electronic equipment housings, and heat sinks.

Properties: Low density, can be anodized for various colors and improved corrosion resistance. Easy to perform shearing and bending operations.

Common Grades: ASTM 5052 (Most common sheet metal grade, good formability, corrosion resistant), 6061 (High strength, heat-treatable), 1100 (Commercially pure aluminum, excellent formability).

Galvanized Steel

Galvanized steel sheets are carbon steel coated with a layer of zinc to provide superior rust protection.

Applications: Suitable for components in outdoor or humid environments requiring weather resistance and corrosion protection, such as HVAC ducts, electrical boxes, and building structures.

Properties: The zinc coating provides sacrificial protection, preventing the steel from rusting even if the surface is scratched to some extent.

Common Grades: SGCC, DX51D+Z (Hot-dip galvanized, good for forming).