Custom Metal Parts For Trucks & Automotive

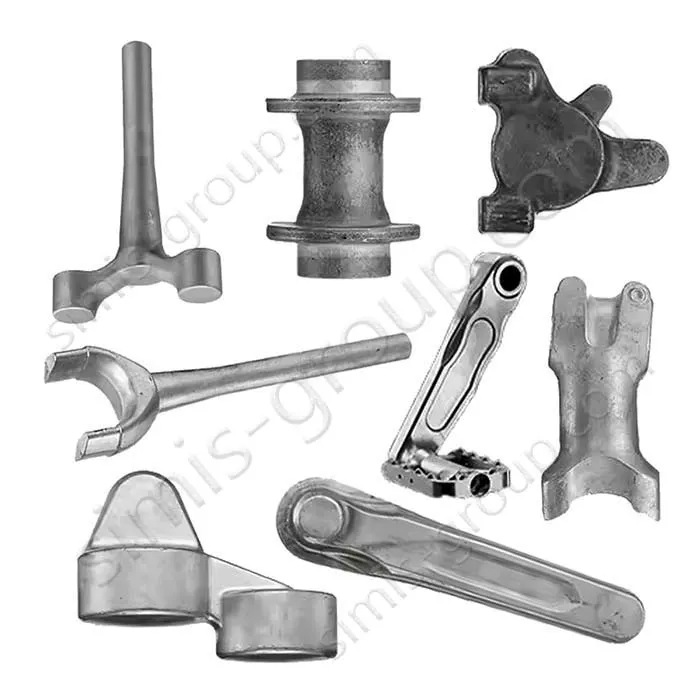

Metal parts for cars and trucks must meet tough demands. We use materials like steel, aluminum, and cast iron. These metals provide the needed high strength, light weight, and resistance to rust and heat. Custom metal parts include many key components: Engine parts (like pistons and crankshafts). Suspension systems (like control arms and shock absorbers). Structural elements (like chassis and frame brackets). Transmission parts (like gears and shafts). We use custom methods like casting, forging, and machining. This ensures parts meet exact specs and can handle the tough life of trucks and cars. This includes heavy loads, high speeds, and bad weather. Custom parts boost the vehicle's performance, fuel efficiency, and service life. They also help keep repair costs low.

Trucks & Automotive Parts Classification

1. Engine Components

The engine is the heart of every truck and car. It is responsible for making power. We use castings for complex parts like engine blocks, cylinder heads, and oil pans. These need detailed shapes and easy casting. We use forgings for parts that need high strength and performance. These include crankshafts, connecting rods, and pistons. These parts must resist fatigue and high heat and pressure.

Castings: Engine block, Cylinder head, Oil pan

Forgings: Crankshaft, Connecting rod, Piston

2. Suspension System

The suspension system gives a smooth ride. It absorbs shocks and keeps the vehicle stable on the road. We use castings for suspension parts with complex shapes, like control arms and strut mounts. We use forgings for parts under high stress. These include suspension links, axle shafts, and steering knuckles. These forged parts must be very durable and resist wear.

Castings: Control arm, Strut mount

Forgings: Suspension link, Axle shaft, Steering knuckle

3.Brake System

The brake system is essential for stopping the vehicle safely. We use castings for brake parts that must handle high heat and pressure. These include calipers, brackets, and housings. We use forgings for parts that face high mechanical stress, wear, and heat changes. These are parts like brake discs, brake drums, and master cylinders.

Castings: Brake caliper, Brake housing, Bracket

Forgings: Brake disc, Brake drum, Master cylinder

4. Chassis and Frame Components

The chassis and frame hold the vehicle together. They provide the main structure and keep all other parts lined up. We use castings for structural elements like frame brackets, crossmembers, and subframes. These parts need high strength and stiffness. We use forgings for heavy-duty components that handle high dynamic loads and need stability. These are parts like frame rails, towing hooks, and suspension mounts.

Castings: Frame bracket, Crossmember, Subframe

Forgings: Frame rail, Towing hook, Suspension mount

5. Transmission System

The transmission system moves power from the engine to the wheels. This allows the vehicle to run well at different speeds. We use castings for the complex housings, like the gearbox, clutch housing, and gear case. These need good structural strength. Forgings are key for parts that must handle high power and dynamic loads. These include gears, transmission shafts, and universal joints.

Castings: Gearbox housing, Clutch housing, Gear case

Forgings: Gear, Transmission shaft, Universal joint

6. Exhaust System

The exhaust system moves bad gases away from the engine. It also helps the vehicle run better. We use castings for parts that need to fight heat, have complex shapes, and last a long time. These include the exhaust manifold, turbo housing, and muffler. We use forgings for parts that must handle high temperatures and stress. These are components like the exhaust pipe, flange, and header.

Castings: Exhaust manifold, Turbo housing, Muffler

Forgings: Exhaust pipe, Flange, Header

7. Steering System

The steering system directs the vehicle. We use castings for parts like steering housings and rack mounts. These need good strength and must resist wear. We use forgings for critical components that must handle high stress and ensure precise control. These include the steering shaft, pitman arm, and tie rods.

Castings: Steering housing, Rack mount

Forgings: Steering shaft, Pitman arm, Tie rod

Available Materials For Trucks & Automotive Parts

Cast Iron in Vehicle Manufacturing

In cars and trucks, cast iron is mainly used for engines, brake systems, and parts that carry heavy loads. It is chosen because it resists wear well and absorbs vibrations. This helps ensure a smooth ride.

Gray Cast Iron:

Uses: It's often sand-cast for engine blocks, cylinder heads, brake discs, and exhaust manifolds.

Benefit: Its great vibration absorption cuts down on engine noise and helps parts keep their size accurately.

Ductile Iron:

Uses: This iron is sand-cast and heat-treated for crankshafts, control arms, suspension mounts, and differential housings.

Benefit: It offers high strength and fights impacts well. This meets the tough, high-load needs of the vehicle's frame.

Alloy Cast Iron:

Uses: After alloying and heat treatment, this iron is used for parts that get very hot and wear quickly. Examples are turbine housings, exhaust pipes, and wear bushings.

Benefit: It ensures reliable, long-term operation in harsh conditions.

Steel in Vehicle Manufacturing

Steel is vital for vehicle parts that bear loads, move power, and ensure safety. We make strong, precise steel parts using casting or forging, stamping, welding, and heat treatment. Steel production includes steps like quenching. This greatly boosts wear resistance and fatigue life. This ensures the frame and suspension can handle heavy loads, shocks, and constant shaking.

Carbon Steel:

Uses: Forged into steering knuckles, connecting rods, gears, and crankshafts.

Benefit: It gives high strength and impact defense. This ensures the vehicle lasts a long time.

Low-Alloy Steel:

Uses: Stamped into body rails, cross members, and bumper beams.

Benefit: It helps make the vehicle lighter. It also improves how the car absorbs crash energy.

Cast Steel:

Uses: Used for casting differential cases and heavy chassis parts.

Benefit: Machining ensures these parts fit together perfectly.

High Manganese Steel:

Uses: Great for high-wear parts on tracked vehicles, like track shoes.

Benefit: Its excellent wear resistance makes these parts last much longer.

Stainless Steel:

Uses: Found in the exhaust system, fuel lines, and fasteners.

Benefit: It fights corrosion well, keeping parts reliable in wet and hot areas.

Aluminum Alloys in Vehicle Manufacturing

Aluminum alloys are key for building modern vehicles. They help cut weight, boost performance, and fight rust. We turn these alloys into many parts using die-casting, forging, extrusion, welding, and machining. Aluminum meets the goal of being lightweight while still ensuring parts have the needed strength, toughness, and precise fit. This keeps cars, motorcycles, and bikes working reliably in both daily life and tough conditions.

Forged Aluminum Alloys:

Features: These alloys have continuous, strong internal fibers, high strength, and excellent toughness.

Uses: They go into high-stress parts like suspension control arms, wheels, steering knuckles, motorcycle frames, and bike cranks. They are lightweight but handle impact and fatigue loads well.

Aluminum-Silicon Alloys:

Features: They are perfect for die-casting. They offer great heat transfer and wear resistance.

Uses: Engine blocks, transmission housings, clutch housings, oil pans, and motor housings. They ensure good heat removal and stable engine function.

Aluminum-Magnesium Alloys:

Features: They are very light and resist rust well.

Uses: Extruded into vehicle doors, bumper beams, roof racks, motorcycle fuel tanks, and subframes. They make the vehicle stronger and last longer.

High-Strength Aluminum Alloys:

Features: They get their strength from special heat treatments.

Uses: Machined into suspension arms, steering parts, lightweight wheels, and high-stress connectors. They are lighter than steel but still carry heavy loads.

Aluminum Extrusions:

Features: Shaped and machined from long profiles.

Uses: Electric vehicle battery boxes, radiators, frame structures, and bike frames. Anodizing or painting improves their look and rust defense.

Other Metal Alloys in Vehicle Manufacturing

Vehicle manufacturing also uses specialty metals for specific needs. These alloys offer unique traits like high electrical flow, wear defense, or lightweight properties. They are chosen for demanding jobs that need top strength, heat defense, or rust resistance.

Magnesium Alloys:

Features: They are extremely lightweight.

Uses: We use die-casting to form parts like steering wheel frames, dashboard brackets, and seat frames. This greatly cuts down the vehicle's weight.

Titanium Alloys:

Features: They offer very high strength and rust resistance.

Uses: They are common in high-performance exhaust systems, suspension bolts, and racing components. They boost both durability and performance.

Copper and Copper Alloys:

Features: They move electricity and heat very well.

Uses: Used in radiators, water pipes, busbars, connectors, and motor windings. Extrusion and machining ensure they conduct heat and electricity efficiently.

Bronze:

Features: Known for its excellent wear resistance.

Uses: Found in plain bearings, bushings, and synchronizer rings. This ensures smooth shifting in the transmission system.

Brass:

Features: Easy to machine and resists corrosion.

Uses: Common in brake line connectors, valve bodies, and electrical terminals. It makes assembly easy and resists rust.

How To Customize Trucks & Automotive Parts

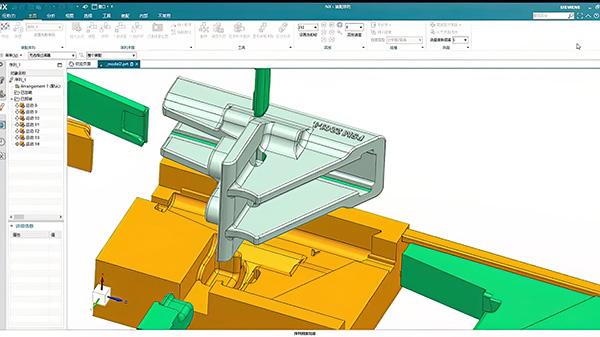

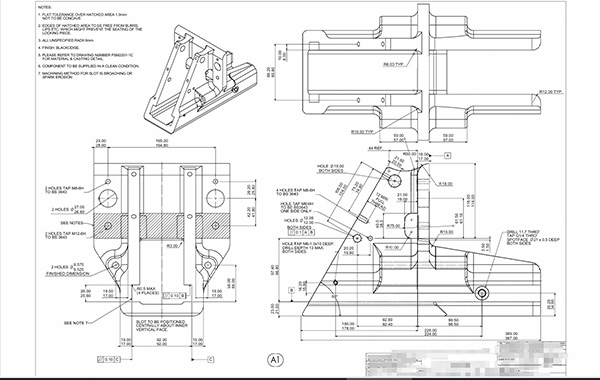

3D Drawings

Processing Drawings

Sample

1. Design Review and Initial Samples

2. Confirm Details: Material, Process, and Performance

3. Make Production Molds and Samples

4. Comprehensive Sample Inspection

5. Mass Production

6. Post-Production Quality Checks

Custom Processing Of Trucks & Automotive Parts

Casting Automotive Parts

In the car and truck industries, casting makes parts like engine blocks, transmissions, and axle housings. These parts have complex shapes and need strong structures. Casting helps boost the part's durability and performance. This is key when parts face heavy loads, high heat, and strong shaking (vibration).

Forging Automotive Parts

In the car and truck industries, forging creates key components. These include parts like crankshafts, gears, suspension parts, and connecting rods. Forged parts for the engine and chassis have excellent strength, toughness, and fight fatigue well. This greatly improves the vehicle's stability and long-term durability.

Heat Treatment For Automotive Parts

In the car and truck industries, heat treatment makes parts perform better. It is used on items like gears, shafts, brake rotors, and valve springs. This process boosts wear resistance and fatigue strength. This ensures that parts work reliably for a long time. For high-performance or heavy-duty vehicles, this step is vital for cutting maintenance costs and improving safety.

Machining For Automotive Parts

In the car and truck industries, machining creates highly precise components. These include parts like engine parts, cylinder heads, and turbochargers. Machining ensures these parts meet tight tolerances (exact size limits). This is crucial for achieving optimal performance, better fuel efficiency, and greater safety.

Sheet Metal Fabrication Automotive Parts

In the car and truck industries, sheet metal fabrication creates the outside structure of vehicles. This includes parts like doors, hoods, and roofs. It is also used for inside components and structural supports. This process is key for the vehicle's strength, safety, and overall look.

Surface Treatments For Automotive Parts

In the car and truck industries, surface treatments are used on many parts. This includes brake components, exhaust systems, and suspension parts. These treatments boost corrosion resistance, wear resistance, and durability. They protect parts from weather and driving factors. This helps cut down on maintenance and makes the parts last longer. Ultimately, this ensures reliable performance in all driving conditions.