Surface Treatment for OEM Custom Manufacturing

Surface Treatment Overview:

SIMIS Group has established long-term strategic partnerships with a number of professional metal parts surface treatment plants. Through close cooperation with surface treatment plants, SIMIS Group is able to provide customers with a variety of advanced and customized metal casting and forging surface treatment solutions, such as electroplating, spraying, anodizing, phosphating, surface coating, etc., to ensure the excellent performance of metal parts in terms of corrosion resistance, wear resistance, oxidation resistance and aesthetics, so as to meet the performance and appearance requirements of metal parts in different industries.

SIMIS Group will continue to strengthen cooperation with various high-quality metal parts surface treatment plants, continuously expand technical boundaries, improve service quality, and provide customized one-stop casting and forging solutions for global customers.

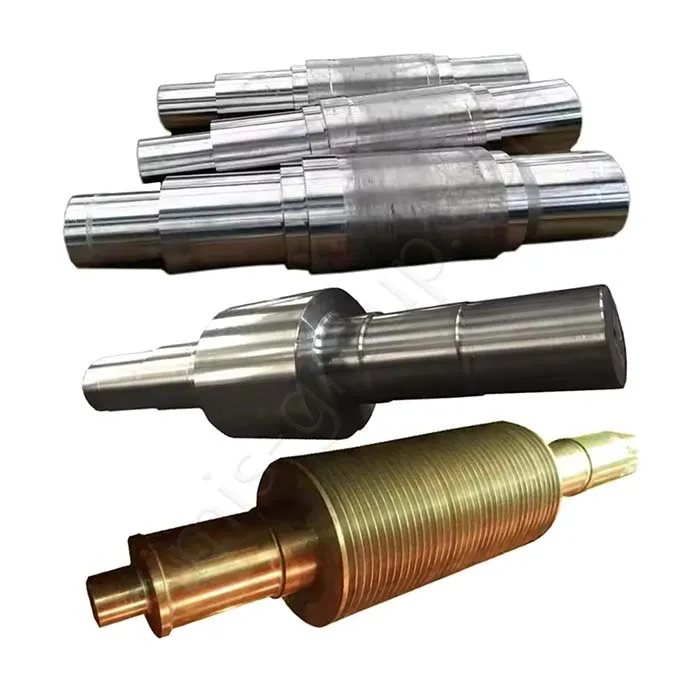

OEM Custom Surface Treatment Parts

Surface Treatment Process for Custom Metal Parts

Surface Treatment process overview

The surface treatment process of metal castings and forgings mainly targets surface defects generated during casting and forging, such as scale, burrs, pores, etc., and improves its surface quality and performance through different treatment methods, and enhances its corrosion resistance, wear resistance and fatigue resistance.

1. Mechanical polishing

The metal surface is rubbed by mechanical equipment and polishing agent to remove the uneven surface and make it smoother. It is suitable for castings and forgings with high requirements for surface finish, such as precision mechanical parts.

2. Sandblasting

The metal surface is impacted by high-speed sprayed sand particles to remove surface oxide scale, dirt and burrs, while increasing surface roughness and improving the adhesion of subsequent coatings.

3. Pickling

The oxide scale, rust and dirt on the metal surface are removed by acidic solutions (such as sulfuric acid, hydrochloric acid, etc.). Pickling can not only clean the surface, but also provide a good adhesion basis for subsequent phosphating, electroplating or spraying processes.

4. Phosphating treatment

Phosphating treatment is a surface treatment process that forms a layer of phosphate film on the metal surface. It is often used to enhance the corrosion resistance of castings and forgings. The phosphate film has good anti-corrosion performance and can serve as a base layer for coating adhesion to improve the durability of subsequent coatings. Phosphating treatment is commonly used for castings and forgings in industries such as automobiles, machinery and home appliances.

· Zinc phosphating

· Iron phosphating

5. Electroplating

A layer of metal (such as nickel, zinc, chromium, etc.) is plated on the metal surface through an electrolytic reaction to form a uniform coating with good corrosion resistance, wear resistance and decorative properties. Electroplating technology is often used for surface treatment of automotive parts, electronic equipment and tools.

· Zinc Plating

· Chromium Plating

· Gold/Silver Plating

6. Chemical plating

Unlike electroplating, chemical plating does not rely on external current, but deposits a coating on the metal surface through chemical reaction. Chemical plating is often used for complex parts that require uniform coatings. It can avoid problems such as uneven current distribution in electroplating and is widely used in precision parts, electronic components and other fields.

· Anodizing

· Electroless Nickel Plating

7. Spraying

A surface treatment method that sprays the paint in the form of aerosol onto the surface of metal or other substrates. Spraying technology is often used to improve the corrosion resistance, wear resistance, decorativeness and oxidation resistance of materials.

The spraying process can not only effectively improve the functionality and aesthetics of the substrate, but also provide a variety of coating thicknesses and performances according to different needs.

· Powder Coating

· Liquid Coating

· Thermal Spraying

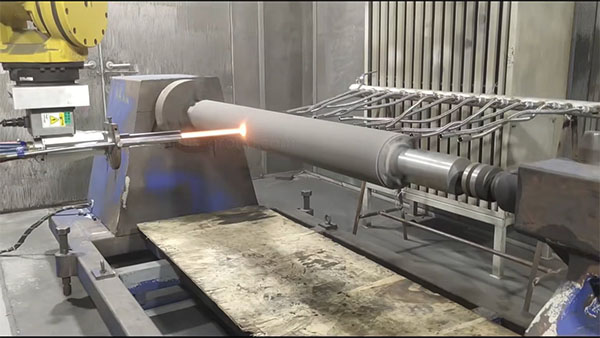

8. Laser Surface Treatment

The metal surface is irradiated with a high-energy laser beam to quickly heat and change the microstructure of the surface metal, thereby improving its wear resistance, hardness, fatigue resistance and other properties. Laser melting spraying, laser surface hardening and other technologies are often used for surface treatment of castings and forgings with high precision requirements, especially in aviation, aerospace, molds and tools.

9. Surface Metallization

By penetrating or diffusing metal atoms into the surface of castings and forgings, an alloy layer with special properties is formed. Common surface metallization processes include aluminizing, carburizing, nitriding, etc. Through these processes, the wear resistance, corrosion resistance and high temperature resistance of the surface of castings and forgings can be significantly improved, and they are often used for surface treatment of engine parts, tools and molds.

· Aluminizing

· Carburizing

· Nitriding

Available Materials for Surface Treatment Applications

What metal parts can surface treatment?

By properly treating different metal castings and forgings, not only can the service life of the castings and forgings be improved, but also their appearance and performance can be improved. The metal materials that Simis Group can surface treat include steel, aluminum alloy, copper alloy, cast iron, copper alloy and magnesium alloy. Steel castings and forgings are often used in electroplating, spraying, phosphating and other processes to improve corrosion resistance, hardness and strength; aluminum alloy castings and forgings are often used in anodizing, spraying and chemical plating to enhance corrosion resistance and improve appearance; copper alloy castings and forgings are mostly electroplated or sprayed to improve wear resistance and corrosion resistance; cast iron castings and forgings are often treated with sandblasting, phosphating and coating to improve wear resistance and corrosion resistance; magnesium alloy castings and forgings can be treated by spraying, anodizing and other methods to enhance their corrosion resistance and heat resistance.

1. Cast Iron

·Gray (Grey) Iron

·Ductile Iron

·Alloy cast iron:High chromium alloy cast iron, High nickel alloy cast iron, Silicon alloy cast iron, …

2. Steel

·Carbon Steel: Mild Steel, Medium Carbon Steel, High Carbon Steel,

·Alloy Steel: Low alloy steel, High alloy steel,

·Stainless steel: Austenitic stainless steel, Ferritic stainless steel, Martensitic stainless steel, Duplex stainless steel, ...

3. Aluminum Alloys

·Aluminum-Silicon Alloys

·Aluminum-Magnesium Alloys

·Aluminum-Zinc Alloys

·…

4. Other Metal Alloys

·Brass

·Bronze

·Nickel alloys

·Titanium alloys

·…