Custom Metal Parts For Energy Power Equipment

Custom casting and forging parts are used in the energy industry. This includes power generation, transmission, storage, and mining. They are also key for renewable and marine energy equipment. These parts are vital for equipment to run well, safely, and stably. Customized parts are strong, resist rust, handle high heat, and are very precise. This lets them work in extreme conditions. It makes equipment last longer and lowers repair costs.

Energy Power Equipment Parts Classification

1. Power generation equipment components

Castings and forgings are key parts for power machines. This includes thermal, hydro, wind, and nuclear power equipment. Examples are turbine housings and main shafts.

These parts must be strong, handle high heat, and resist fatigue. They work well under high pressure, high speed, and heavy stress. They give strong support for the efficient energy work of the machines.

Castings: Turbine housing, Guide vane housing, Wind turbine hub, Base

Forgings: Steam turbine main shaft, Rotor, Blade root

2. Power transmission and distribution equipment components

Castings and forgings are used in power lines and distribution gear. This includes transformer housings, joints, terminals, and support frames. They protect, conduct electricity, and provide support.

Their great conductivity, rust resistance, and stable structure ensure power moves well. They also ensure the equipment lasts a long time.

Castings: Transformer housing, Transformer oil tank, Cable junction box

Forgings: High-voltage conductor connectors, Terminals, Insulator supports

3. Energy storage equipment components

Castings and forgings are used in battery and mechanical energy storage. They make key parts like housings, heat sinks, and support frames.

These parts offer great sealing, rust resistance, and high strength. This ensures the equipment stays cool and mechanically stable.

Castings: Energy storage equipment housing, Heat sink, Sealing valve seat

Forgings: High-strength connectors, Support frames

4. Structural support components

Large energy equipment needs very strong support. Castings and forgings provide high rigidity and durability. Examples are equipment bases and support shafts. They work well under heavy loads and in complex places. This ensures the equipment stays stable and precise.

Castings: Equipment supports, Bases, Tower flanges

Forgings: Support shafts, Couplings, Bolts, Nuts

5. Energy extraction equipment components

Castings and forgings are used in energy drilling and mining. This includes oil, natural gas, and geothermal work. Parts like wellhead housings and pipe joints face extreme pressure, rust, and high heat. Their great strength and durability provide long-term support for getting energy out of the ground.

Castings: Wellhead housing, Pump housing, Mud pump cylinder sleeve

Forgings: Drill pipe joints, Valve bodies, High-pressure seals

6. Renewable energy equipment components

Castings and forgings are used in wind, solar, and marine energy gear. They make parts like wind hubs, tower bases, and solar brackets.

These parts fight fatigue, are very strong, and resist rust. They handle changing natural conditions well. They are key for using renewable energy efficiently on a large scale.

Castings: Wind turbine hub, Tower foundation, Photovoltaic bracket connector, Tracking system base

Forgings: Wind turbine shaft, Ocean energy device main shaft, Turbine blade root

7. Marine energy and offshore equipment components

Castings and forgings are key for marine and offshore gear. They are widely used in marine power devices, oil platforms, FPSOs, and underwater pipes.

Key parts include shafts, foundation piles, support frames, and pipe joints. These parts resist seawater rust, are very strong, and fight fatigue. They can handle the tough sea environment and complex loads.

Castings: Platform support feet, Mud pump housings, Pipe fixing brackets, Equipment housings

Forgings: Lifting hooks, Mooring chain links, High-pressure valve bodies, Fasteners, Connecting flanges

Available Materials For Energy Power Equipment Parts

Cast Iron in Energy and Power

Cast iron is used in the oil, energy, and power generation industries. It is made into many different parts using sand casting, lost foam casting, and heat treatment.

Gray Cast Iron

Gray cast iron absorbs vibration very well. After casting, it is used for pump bodies, valve bodies, and gear housings. This reduces shake and keeps machines stable.

Ductile Iron

Ductile iron is very strong and tough. Casting makes it good for rotors, pump casings, compressor parts, and bearing seats. It can handle shock and heavy loads.

Alloy Cast Iron

Alloy cast iron fights wear and high heat. It is used in pump impellers, valve discs, and high-temperature parts. Some parts can be made better with extra heat treatment or finishing.

Steel in Petroleum, Energy, and Power

Steel is key for oil, energy, and power machines. Steel parts are forged, cast, and treated to resist loads and wear.

Carbon Steel

Carbon steel is strong and tough. It is forged or cast into parts like pump shafts, rods, and gears. It handles high torque and shock loads.

Carbon steel parts in petroleum, energy, and power: Pump shafts, Drive shafts, Connecting rods, Gears, Hydraulic rods

Low-Alloy Steel

Low-alloy steel fights wear and fatigue well. It is good for hydraulic pump housings, valve bodies, and connectors. It ensures stable, long-term use.

Low-alloy steel parts in petroleum, energy, and power: Hydraulic pump housings, Valve bodies, High-stress connectors, Brackets

Cast Steel

Cast steel is easy to shape. Casting makes large parts like pump bodies, turbine housings, and generator bases. This ensures accurate size and strong mechanical properties.

Cast steel parts in petroleum, energy, and power: Pump bodies, Turbine housings, Generator bases, Compressor housings

High-Manganese Steel

High-manganese steel fights wear and impact. It is cast and treated to make mill liners, rollers, and pump impellers. It is fit for high-load and shock conditions.

High-manganese steel parts in petroleum, energy, and power: Coal mill liners, Conveyor rollers, Crusher rollers, Pump impellers

Stainless Steel

Stainless steel resists rust and chemicals very well. It is cast or machined into pump bodies, valves, and fasteners. It stays stable in wet, chemical, or rusty places.

Stainless steel parts in petroleum, energy, and power: Pump bodies, Valve bodies, Pipe joints, Fasteners

Aluminum Alloy in Oil, Energy, and Power

Aluminum alloys are used in oil, energy, and power machines. They make parts that are light and fight rust. They are made using casting, extrusion, and machining.

High-Strength Aluminum Alloys

These alloys are light but very strong. They are used for instrument housings, brackets, and light frames. Casting or extrusion makes parts lighter while keeping strength high.

High-strength aluminum alloys: Instrument housings, Control panel brackets, Lightweight structural components

Corrosion-Resistant Aluminum Alloys

These alloys form a strong rust-proof film on the surface. They are used for pump guides, valve plates, and fasteners. Casting or machining makes them last longer.

Corrosion-resistant aluminum alloys: Pump guides, Valve plates, Fasteners

Easy-to-Machine Aluminum Alloys

These alloys are simple to machine and weld. They are good for complex shapes like end caps, shrouds, and electrical boxes. Heat treatment can make them stronger and tougher.

Easy-to-machine aluminum alloys: End caps, Shrouds, Electrical boxes

Other Metal Alloys in Oil, Energy, and Power

Beyond iron, steel, and aluminum, the energy sector uses special metals. These parts must handle high heat, high pressure, rust, and wear.

Copper and Copper Alloys

These alloys conduct electricity well and resist wear. They are used for pump bushings, valve seats, and electrical contacts. They are made using casting or machining.

Titanium Alloys

These are very strong and resist rust well. They are good for making pump blades, fasteners, and high-temperature pipe supports. They are made by forging or machining.

Magnesium Alloys

These alloys are very light and easy to machine. They are used for instrument housings and light brackets. Casting and machining lowers the equipment's total weight.

Molybdenum and Molybdenum Alloys

These alloys resist high heat and wear. They are used in hot furnace parts, brake parts, bearing seats, and pump impellers. They are made by casting or forging.

How To Customize Energy Power Equipment Parts

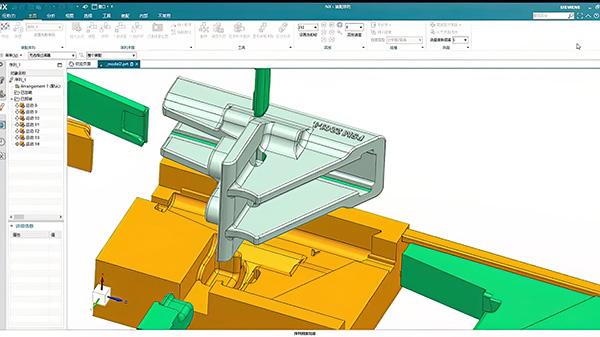

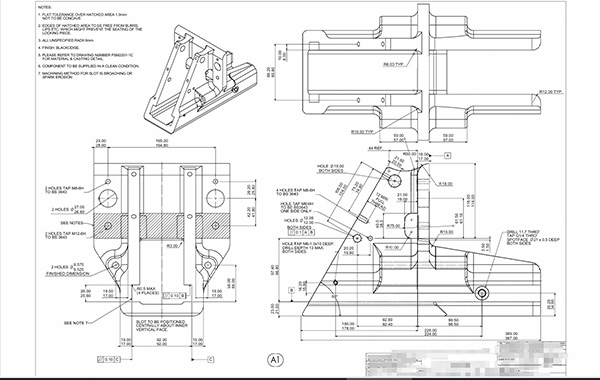

3D Drawings

Processing Drawings

Sample

1. Provide Design Documents or Samples

2. Confirm Material, Process, and Performance

3. Make Molds and Samples

4. Comprehensive Sample Inspection

5. Mass Production

6. Post-Production Parts Multiple Quality Inspections

Custom Processing of Energy Power Equipment Parts

Casting Energy Power Equipment Parts

Casting makes large and complex parts for power systems. This includes turbine housings, generator housings, and pump bodies. Casting gives custom parts high strength and wear resistance. This allows them to handle the high pressure and high heat common in energy work.

Forging Energy Power Equipment Parts

Forging makes key parts for energy machines. This includes turbine blades, shafts, and valve bodies. These forgings strongly resist fatigue. They have high strength and toughness. This lets the parts work reliably for a long time in high-stress places like power plants.

Heat Treatment

Heat treatment makes energy parts work better. This is used for items like turbine blades, pressure vessels, and pump components. We improve properties like wear resistance and fatigue strength. This allows the parts to handle the high heat, high pressure, and non-stop work of power machines. This increases how long the products last and how reliable they are.

Machining

Machining makes high-precision parts for the energy sector. This includes turbine shafts, pump impellers, and generator rotors. Machining ensures parts meet very strict size rules. They fit correctly into complex machines. This lets the machines run smoothly and well. It also means less friction and maximum reliability in power systems.

Sheet Metal Fabrication

Sheet metal work makes structural parts for energy machines. This includes heat exchangers, housings, and supports for generators and turbines. These parts are used to build power systems. They ensure the equipment runs reliably under mechanical stress and tough weather.

Surface Treatment

Surface treatment is put on energy parts. This includes turbine blades, pressure vessels, and heat exchangers. It protects them from rust and wear caused by the environment. This process makes key parts last longer. It lowers repair costs. It also makes power equipment work better and more reliably overall.