Custom Metal Parts For Rail Train

Custom casting or forging makes metal parts for the railway industry. These parts are made for specific needs. This includes brake systems, wheels, axles, couplings, and structural parts. These parts often use strong materials like steel or iron. We use precise design and custom processes. This ensures the parts are durable and fight wear and rust. They can handle heavy loads, high speeds, and changing weather well.

Rail Train Parts Classification

1. Wheel and Axle Assembly

The wheel and axle assembly is key for train stability and movement. It provides support and traction. Castings are used for parts with complex shapes and structural integrity. This includes wheel hubs and axle housings. Forgings are used for axles and wheels. Forgings ensure high strength, durability, and they resist fatigue. This is needed for heavy loads and constant use.

Castings: Wheel hubs, Axle housings

Forgings: Train wheels, Axles

2. Brake System

The brake system keeps the train safe. It stops and controls the train well, even when it is fast or carrying heavy loads. Castings are often used for parts like calipers or housings. These parts need complex shapes and high strength. Forgings are for critical parts like brake discs or pistons. They must have very high wear resistance and mechanical strength.

Castings: Brake calipers, Brake housings

Forgings: Brake discs, Brake pistons

3. Coupling System

The coupling system joins train carriages. It transfers power and keeps the structure strong when the train moves. Castings are used for the outer coupling housings. Forgings are key for the main coupler components. They must handle high forces. They provide long-term reliability under dynamic conditions.

Castings: Coupling housings

Forgings: Couplers, Coupling pins

4. Suspension System

The suspension system holds the train's weight. It also absorbs track vibrations. This ensures the train runs smoothly. Castings are used for parts like suspension brackets or housings. Forgings are used for items like springs or leaf spring brackets. These parts take high loads and stress.

Castings: Suspension brackets, Housings

Forgings: Suspension springs, Leaf spring brackets

5. Frame and Chassis

The frame and chassis are the foundation of the rail train. They provide the necessary strength and stiffness to hold all other parts. Castings are used for complex frame components and support brackets. Forgings are used for critical load-bearing parts like cross members. Forgings ensure the structure is robust under extreme stress.

Castings: Frame components, Support brackets

Forgings: Cross members, Chassis components

6. Engine Components

Engine parts make the power that runs the train. Castings are used for engine blocks and various housings. Forgings are used for parts like crankshafts and connecting rods. They must handle high stress, heat, and wear over a long time.

Castings: Engine block, Oil pan

Forgings: Crankshaft, Connecting rods

7. Railway Track Components

Railway track components keep the rails held down and straight. Castings are used for items like rail chairs, baseplates, and fishplates. These parts handle complex loads. Forgings are used for parts like rail clips and fasteners. They must be very strong and maintain tight tolerances.

Castings: Rail chairs, Baseplates, Fishplates

Forgings: Rail clips, Track fasteners

Available Materials For Rail Train Parts

Cast Iron in Railway Systems

Cast iron is used in trains and track systems. It is made into many different parts using sand casting, lost foam casting, and heat treatment.

Gray Cast Iron

Gray cast iron absorbs vibration very well. It is used in parts like brake discs and gearbox housings. This helps to lower operating noise.

Ductile Iron

Ductile iron is very strong and tough. Casting makes it suitable for parts that take impact and fatigue. Examples include wheel centers, bogie parts, and coupler dampers.

Alloy Cast Iron

Alloy cast iron fights wear and high heat. Casting and alloying make it good for high-friction or hot parts like brake shoes and engine cylinder liners. Some parts get extra forging or heat treatment for better performance.

Steel in Railway Industry

Steel is made into many different parts for the railway industry. This is done through casting, forging, and heat treatment.

Carbon Steel

Carbon steel is strong and tough. Forging ensures strong fiber flow. It is used in parts that take high impact, such as axles, couplers, and drawbars.

Carbon steel: Axles, Couplers, Drawbars

Low-Alloy Steel

Low-alloy steel fights wear and fatigue well. After forging, it is good for bogie parts and high-stress connectors.

Low-alloy steel: Bogie components, High-stress connections

Cast Steel

Cast steel is easy to shape. Casting meets the size needs of large, complex parts. This includes bogie sideframes, bolsters, and buffer housings.

Cast steel: Bogie sideframes, Bolsters, Buffer housings

High-Manganese Steel

High-manganese steel fights wear and impact. Casting and treatment make it good for turnout rails, frogs, and rail joints. It handles heavy loads and high speeds.

High-manganese steel: Turnout rails, Frogs, Rail joints

Aluminum Alloy in Railway Systems

Aluminum alloys are made into many different parts for trains and track systems. This uses die casting, sand casting, heat treatment, and precision machining.

High-Strength Aluminum Alloys

These alloys are light but very strong. Die casting or extrusion makes them into body panels, door frames, and seat structures. This lowers the vehicle's weight while keeping the structure strong.

High-strength aluminum alloys: Vehicle body panels, Door and window frames, Seat structures

Corrosion-Resistant Aluminum Alloys

These alloys create a strong rust-proof film on the surface. Casting or machining makes them into brake guides, decor parts, and fasteners. This makes the parts last longer.

Corrosion-resistant aluminum alloys: Brake guides, Decorative parts, Fasteners

Machinable Aluminum Alloys

These alloys are easy to machine and weld. They are good for complex shapes like end caps, shrouds, and electrical boxes. Heat treatment makes them stronger and tougher. This ensures stable, long-term use.

Machinable aluminum alloys: End caps, Shrouds, Electrical equipment housings

Other Metal Alloys in Rail Systems

Besides iron, steel, and aluminum, special alloys are used in train parts. These alloys are chosen for their top-level performance. This includes high heat resistance, rust resistance, or high strength for extreme uses.

Copper Alloys

Copper and copper alloys are cast and machined for parts that conduct electricity and fight wear.

Red copper conducts electricity well and resists wear. It is used in busbars, contactors, and slip rings. This keeps electric systems stable.

Bronze and lead bronze fight wear and friction. They are cast into bearings, bushings, brake guides, and gear sleeves. This makes parts last longer.

Titanium Alloys

Titanium alloys are light, very strong, and resist rust. Forging or machining makes them into body parts, springs, and fasteners. This improves efficiency and durability in fast or special-duty trains.

Titanium alloys: Vehicle body components, Springs, Fasteners, High-performance mechanical parts

Magnesium Alloys

Magnesium alloys are very light and easy to machine. Die-casting makes them into body panels, interior brackets, and instrument panels. This greatly reduces the train's weight.

Magnesium alloys: Vehicle body panels, Interior brackets, Instrument panels

How To Customize Rail Train Parts

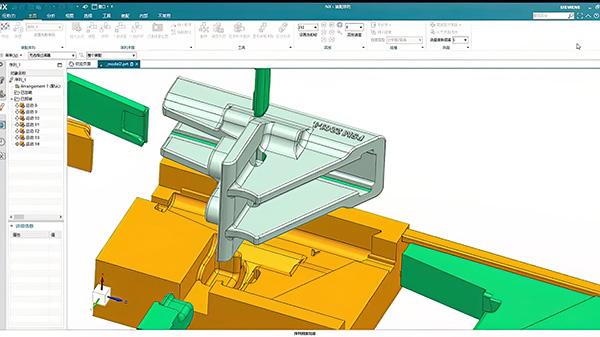

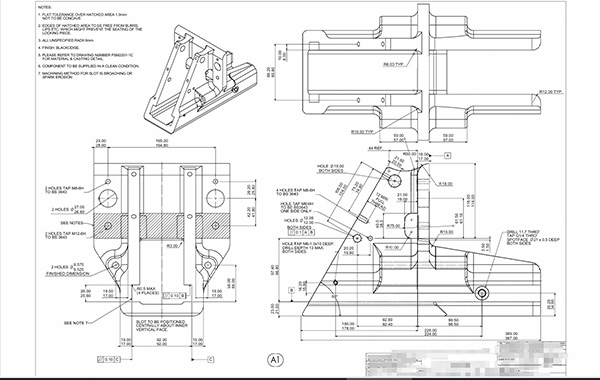

3D Drawings

Processing Drawings

Sample

1. Provide Design Documents or Samples

2. Confirm Material, Process, and Performance

3. Make Production Molds and Samples

4. Comprehensive Sample Inspection

5. Mass Production

6. Post-Production Parts Multiple Quality Inspections

Custom Processing of Rail Train Parts

Casting in Railway Train Parts

Casting makes metal parts for the train industry. This includes train wheels, brake housings, and engine blocks. These parts are made in many sizes and complex shapes. They must have high structural integrity and durability. This helps them handle the heavy loads, vibrations, and weather of railway systems.

Forging in Railway Train Components

Forging makes high-strength parts for trains. This includes axles, suspension parts, and coupling mechanisms. These forged components fight fatigue very well. They have excellent mechanical strength. This ensures the train system is safe, reliable, and lasts longer under extreme working conditions.

Heat Treatment

Heat treatment is used to make railway parts better. This is done for items like train wheels, rails, and axles. It makes parts tougher and improves their wear resistance and fatigue strength. This is vital for railway parts that face constant friction, high pressure, and heat changes.

Machining in Railway Train Parts

Machining ensures critical train parts meet strict size and quality rules. This includes engine parts, bearing seats, and gears. High precision ensures railway systems work safely and efficiently.

Sheet Metal Fabrication

Sheet metal processing makes parts for trains. This includes body panels, internal frames, and safety shields. Sheet metal gives components that are lightweight and durable. This improves the train's overall structural strength, safety, and performance.

Surface Treatment

Surface treatments are used on train parts. This includes galvanizing, anodizing, and coating. They protect parts from rust, wear, and weather damage.Train parts like wheels, axles, and brake systems often get this treatment. This makes them last longer and stronger. It also lowers maintenance and extends the life of critical parts that work in harsh conditions.