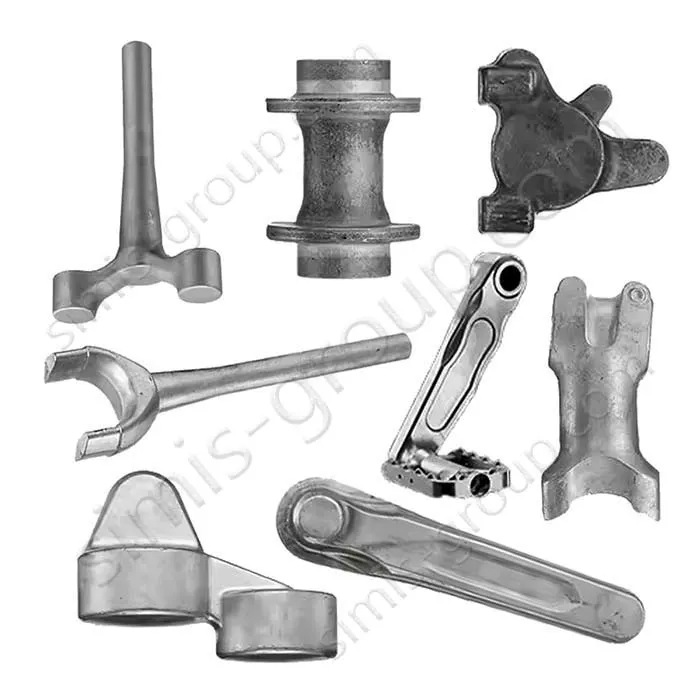

Custom Crank Manufacturer

Crank

China Simis Company is a specialized OEM custom manufacturer of high-stress Cranks and Crank Arms. These components are fundamental links in mechanical transmission systems, converting linear motion into rotational motion (as in an engine) or vice versa (as in a pump or compressor). They operate by transferring significant forces and torque.

Cranks are subjected to high cyclical loads, reversing bending stress, torsional strain, and constant fatigue. The integrity of the material and the precision of the geometry are non-negotiable safety requirements. We utilize both Precision Forging (for maximum strength) and High-Integrity Casting (for complex shapes) to produce robust parts from Alloy Steel, Ductile Iron, and Aluminum Alloy, ensuring superior fatigue life, structural rigidity, and optimal dynamic balance.

What Are the Manufacturing Processes for Crank and Crank Arm?

The choice between forging and casting is determined by the component's required fatigue life and the complexity of its shape. We mainly adopt 4 core processes including Closed Die Forging, High-Integrity Casting, Heat Treatment and Precision CNC Machining to meet different crank and crank arm production needs.

| Manufacturing Process | Material Focus | Component Type & Key Advantage |

| Closed Die Forging | Alloy Steel (e.g., AISI 4140, 4340), High-Strength Aluminum. | Safety-Critical Parts (Engine/Compressor Cranks); delivers superior grain flow alignment, maximum density, and the highest fatigue life and toughness necessary for extreme cyclical loads. |

| High-Integrity Casting (Sand/Shell/Investment) | Ductile Iron, Alloy Steel. | Complex Cranks, Balance Weights, or Lever Arms; allows for near-net shape production and the inclusion of intricate features that cannot be forged. |

| Heat Treatment | Alloy Steel, Ductile Iron. | Mandatory processes like Quenching & Tempering (Q&T) are performed to achieve the required hardness, yield strength, and resistance to wear in bearing areas. |

| Precision CNC Machining | All Alloys. | Critical. Required for finishing bearing journals, mounting interfaces, and, most importantly, achieving the precise geometry for dynamic balance. |

How to Select Crank and Crank Arm Materials?

The material must exhibit high tensile and yield strength to handle peak loads, and excellent endurance limits to survive high-cycle fatigue. We provide 3 main material types including Forged Alloy Steel, Cast Ductile Iron and Forged/Cast Aluminum Alloy for crank and crank arm production, each with specific performance advantages.

| Material Type | Primary Performance Requirement | Typical Crank Arm Application |

| Alloy Steel (Forged) | Maximum fatigue strength, toughness, and superior wear resistance for bearing journals. | Internal combustion engine crankshafts, heavy-duty compressor cranks, and high-load hydraulic levers. |

| Ductile Iron (Cast) | Good strength/stiffness and vibration damping at a lower cost than forging. | Automotive or pump crank arms and counterweights where cyclical loads are moderate. |

| Aluminum Alloy (Forged/Cast) | Lightweighting and high stiffness; used primarily to reduce inertia and improve responsiveness. | High-speed, low-load applications or specialized automotive components. |

| Fatigue Life | Endurance Limit. | The material must be carefully selected and processed to ensure the part operates below its endurance limit under normal conditions. |

What Measures Ensure Precision Machining and Quality Assurance for Cranks and Crank Arms?

The function and lifespan of a crank depend on its geometric accuracy, balance, and surface finish in contact areas. Our core quality assurance measures include dynamic balancing calibration, surface integrity control, non-destructive testing (NDT) and hardness/microstructure verification.

·Dynamic Balancing:

High-precision CNC machining is used to adjust the mass distribution (often by drilling balance holes) to achieve the required dynamic balance tolerance, which is vital to minimize vibration and bearing wear in high-speed machinery.

·Surface Integrity:

Bearing journals and pin surfaces are machined to extremely tight tolerances (IT5/IT6) and ultra-low surface roughness (Ra < 0.4μm) to ensure proper oil film formation and minimize wear.

·Non-Destructive Testing (NDT):

Magnetic Particle Inspection (MPI) or Ultrasonic Testing (UT) is mandatory on all safety-critical forged or cast steel components to detect surface cracks or internal voids that could lead to fatigue failure.

·Hardness/Microstructure:

Post-heat treatment checks are performed to verify the material achieved the specified hardness and required microstructure (e.g., tempered martensite).

What Are the Key Applications for Simis Custom Cranks and Crank Arms?

Our custom components are essential for motion transfer in high-stress mechanical systems. The main application fields include Automotive & Engine, Compressors & Pumps, Wind Turbines and Hydraulic Systems.

·Automotive & Engine:

Crankshafts and connecting rod ends for various engines and transmissions.

·Compressors & Pumps:

Cranks and levers for reciprocating compressors (e.g., refrigeration) and industrial pump systems.

·Wind Turbines:

Heavy-duty pitch control crank arms and mechanical linkage components.

·Hydraulic Systems:

High-strength lever arms and pivots subjected to high static and cyclical hydraulic forces.

What Are the Advantages of Simis OEM Custom Cranks and Crank Arms?

Partnering with Simis for custom cranks and crank arms ensures maximum component strength, reliability, and precision:

·Dual Process Mastery:

We offer specialized expertise in both High-Strength Forging (for supreme fatigue life) and High-Integrity Casting (for complex geometries), selecting the optimal process for the application's stress profile.

·Dynamic Balance Precision:

We combine advanced CNC machining with specialized balancing equipment to ensure the final product meets the strictest dynamic balance standards, guaranteeing smooth, vibration-free operation.

·Material Integrity Control:

We maintain rigorous control over the alloy composition and heat treatment to maximize the material's fatigue endurance limit and achieve the necessary surface hardness for wear resistance.

·Integrated Supply Chain:

We handle the entire process: material selection, forging/casting, high-spec heat treatment, ultra-precision CNC machining of journals, and mandatory NDT for safety certification.

How to Get a Quote for Custom Cranks and Crank Arms?

China Simis Company is your expert global partner for custom forging or casting Cranks and Crank Arms, engineered for superior fatigue life, maximum torsional strength, and precise dynamic balance.

Please submit your 2D technical drawings, 3D models (showing bearing journal dimensions), and specific requirements for material grade, target fatigue life (cycles), and required dynamic balance tolerance to our engineering department for a consultation and detailed quotation.