Manufacturing Capabilities of Copper Casting Foundry

Copper Sand Casting

Copper alloy sand casting involves pouring liquid copper alloy (such as brass, bronze, high-strength brass, etc.) into a sand mold to form the shape. It has low mold cost, high production flexibility, and is suitable for medium to low batch production of copper alloy parts of various sizes.

Cast Weight Range: 0.5 kg – 1,000 kg

Max Dimensions: Up to 2 m

Dimensional Tolerance Grade: CT10 to CT13 Grade

Surface Roughness (Ra): Ra 25.0 to 50.0 μm

Minimum Wall Thickness: 6 mm to 10 mm

Copper Die Casting

Copper alloy die casting involves rapidly injecting liquid copper alloy (mainly brass) into a steel mold under high pressure to solidify and form a solid. It has extremely high production efficiency, excellent dimensional accuracy, and excellent surface finish, making it suitable for mass production of small, complex copper castings with high appearance requirements.

Cast Weight Range: 0.02 kg – 1 kg

Max Dimensions: 0.25 m x 0.15 m x 0.1 m

Dimensional Tolerance Grade: CT5 to CT7 Grade

Surface Roughness (Ra): Ra 0.8 to 3.2 μm

Copper Gravity Casting

Copper alloys gravity permanent mold casting utilizes gravity to pour liquid copper alloys into a reusable metal mold (hard mold) for solidification. This method offers a long mold life and low internal porosity. It is suitable for mass production of medium-sized copper castings requiring high airtightness, pressure resistance, and appearance quality.

Cast Weight Range: 0.5 kg – 30 kg

Max Dimension: 0.6 m x 0.4 m x 0.3 m

Dimensional Tolerance Grade: CT8 to CT10 Grade

Surface Roughness (Ra): Ra 6.3 to 12.5 μm

Copper Shell Mold Casting

Copper alloy shell casting involves pouring liquid copper alloy into a thin-shell mold made of resin-coated sand. It offers superior dimensional accuracy and surface finish compared to traditional sand casting, and is suitable for complex copper alloy parts requiring less machining allowance, a good appearance, and medium to large-volume production.

Cast Weight Range: 0.1 kg – 50 kg

Max Dimensions: 0.8 m x 0.6 m x 0.4 m

Dimensional Tolerance Grade: CT7 to CT9 Grade

Surface Roughness (Ra): Ra 6.3 to 12.5 μm

Minimum Wall Thickness: 3 mm to 6 mm

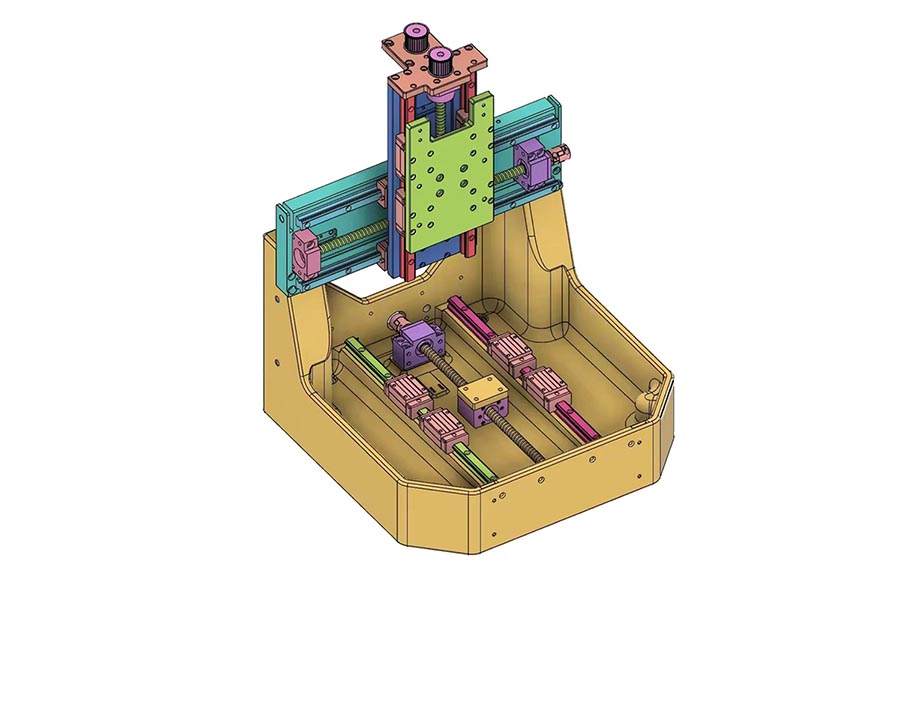

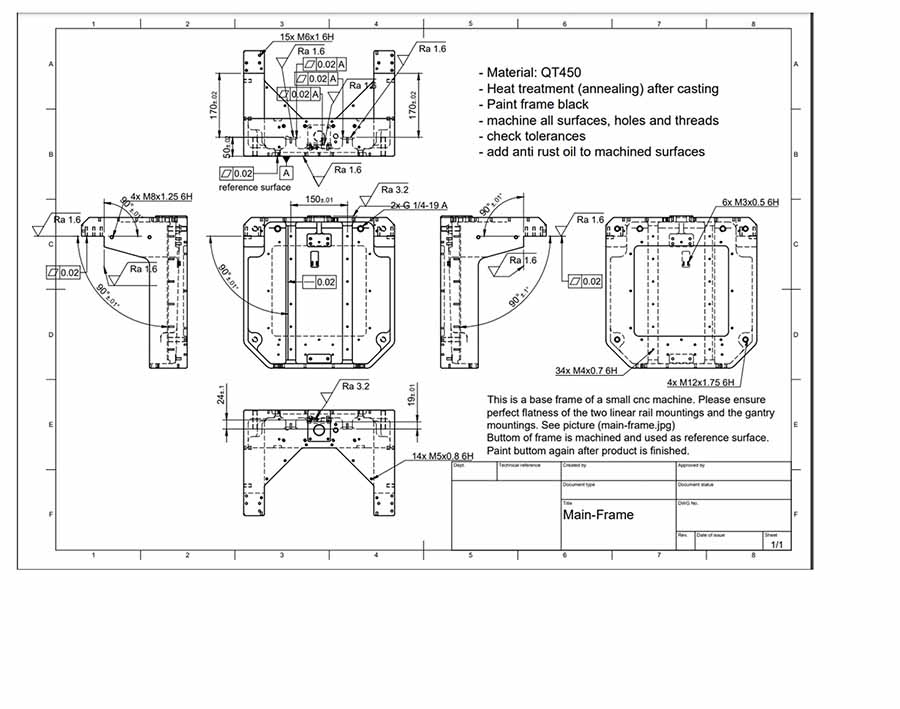

Machining

Machining is used to eliminate casting defects in copper alloy castings, achieve high-precision fits, and produce excellent surface finishes. SIMIS Copper Foundry possesses strong machining capabilities, ensuring that critical flatness, coaxiality, thread accuracy, and sealing surface finish meet customers' stringent requirements when handling complex castings.

Machining Tolerance: IT7 to IT5 Grade

Surface Finish (Ra): Ra 3.2 to 0.4 μm

Max Machining Travel: X 1000 mm / Y 600 mm

Thread Precision: Up to 6H/6g Grade

Surface Treatment

Surface treatment is used to enhance the commercial value of copper alloy parts, improve their functionality, enhance their appearance, and prevent oxidation and discoloration. SIMIS Copper Foundry offers a variety of surface treatment processes to meet customers' stringent requirements for the aesthetics and durability of copper castings.

Blasting/Peening: Casting cleanup; matte surface.

Mechanical Polishing/Grinding: Aesthetic finish; plating base.

Electroplating (Nickel/Chrome): Ultimate wear resistance; high anti-corrosion.

Chemical Passivation: Anti-oxidation; preserves natural color.

Coating/Blackening: Color protection; special aesthetic effects.

OEM Custom Cast Copper Parts by Copper Foundry

Cast Copper Materials for Custom Casting Applications

Brass Casting

Brass is an alloy of copper and zinc. It resists rust very well. It offers good mechanical strength, a nice golden look, and casts easily. It is also easy to machine and costs less. This makes brass good for many decorative and working parts.

Brass Castings from Simis Copper Foundry:

Marine hardware and fittings;

Valves, pumps, and plumbing parts;

Door handles and fixtures for buildings;

Musical instruments;

Electrical connectors;

Decorative art pieces.

Simis can cast brass types:

Low Zinc Brasses (Red Brasses, Zinc < 15%): Plumbing valves and fittings, pump parts, and marine hardware that fights rust.

High Zinc Brasses (Yellow Brasses, Zinc 15-40%): General hardware, decorative items, and architectural fittings.

Leaded Brasses: High-volume parts needing excellent machining, like valves and fittings.

Silicon Brasses: Parts that must hold pressure, marine hardware, and jobs needing high strength and rust resistance.

Aluminum Bronze Casting

Aluminum bronze is an alloy primarily composed of copper and aluminum. It delivers high strength, effective wear resistance, and good corrosion resistance. We use heat treatment to optimize the balance of strength and toughness specific to the application requirements.

Aluminum Bronze Castings from Simis Copper Foundry:

Heavy-duty bearings and bushings;

Gear parts and worm wheels;

Valve stems and seats;

Pump impellers and casings;

Marine hardware and propeller parts;

Chemical processing equipment;

Mining machine parts.

Simis can cast aluminum bronze types:

Single-Phase Bronzes (Al < 8%): Chemical process equipment, seawater pipe systems, and parts needing good shape change.

Duplex Bronzes (Al 8-11%): Strong general-purpose parts like bearings, gears, valve components, and marine hardware.

Complex Bronzes (with Ni, Fe, Mn added): Tough jobs in chemical processing, marine work, and high-heat service.

Tin Bronze Casting

Tin bronze is a traditional alloy composed of copper and tin. It features high wear resistance and good corrosion resistance. This makes it suitable for high-load, slow-speed applications and general industrial requirements.

Tin Bronze Castings from Simis Copper Foundry:

Bushings, bearings, and thrust washers;

Gears and worm wheels;

Valve parts and pump parts;

Marine hardware and propeller fittings;

Architectural pieces;

Electrical contacts.

Simis can cast tin bronze types:

Low Tin Bronzes (Sn < 8%): General-purpose bearings, valve parts, pump parts, and marine fittings.

High Tin Bronzes (Sn 8-12%): High-load bearings, worm gears, heavy machine parts, and industrial bearings.

Phosphor Bronzes (with P added): Electrical springs, contacts, bellows, and precise instrument parts.

Leaded Tin Bronzes: High-speed bearings and bushings. Perfect for jobs where oiling might not be enough.

Other Bronze / Copper Alloy Casting

Bronze is a copper alloy mixed with tin or other elements, such as aluminum or phosphorus. It provides high strength, good wear resistance, and reliable corrosion resistance, making it suitable for components subjected to heavy loads and friction. It is often used for copper alloy components in high-load, slow-speed applications and harsh operating environments.

Bronze Castings from Simis Copper Foundry:

Bushings, bearings, and thrust washers;

Valve parts and pump parts;

Architectural fittings.

Simis can cast bronze types:

Silicon Bronzes: Valve parts, pump parts, architectural fittings, and electrical connectors.

Leaded Bronzes: High-load, slow-speed bearings, bushings, and washers. Perfect for jobs where oiling might be poor.

Industries Served by Our Copper Casting Foundry

How to Customize Copper Castings with Copper Foundry

Confirm customization requirements

Design Review and Samples

Simis engineers first check the 3D and plane drawings. This makes sure your design is ready for manufacturing. If you have a sample part, we can make the new parts based on that sample.

Define Part Requirements

We confirm what the part needs to do. This includes things like its strength, hardness, wear, and rust resistance. We also set the exact size, tolerance, and finish quality needed.

Confirm Casting Material

Our engineers help you pick the right cast copper material. This choice depends on where the part will be used and your technical needs. We give advice based on material cost, strength, and resistance to wear or rust.

Choose the Casting Method

We select the best casting process for your part. We base this choice on your price goal, the part’s shape, its required accuracy, and the material.

Make Molds and Samples

We build the casting molds using your approved drawings or samples. Then, we cast the first batch of samples using the chosen material and process.

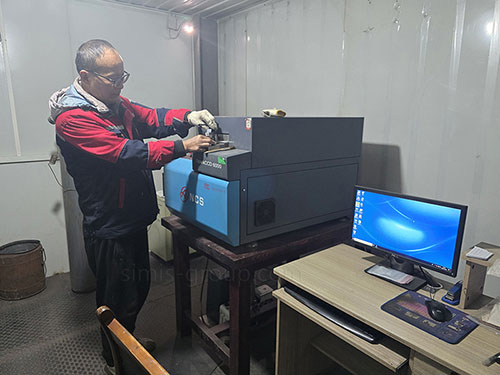

Full Sample Inspection

The finished samples go through a full check. This confirms they meet all design standards and your quality demands. We give you reports covering size, performance, material makeup, and non-destructive testing.

Production and quality control

Mass Production

After you check and approve the sample, we start the mass production plan. We get all the materials ready based on your order. We use the exact same machines and process as we did for the sample. This makes sure every single part we make is the same.

Quality Control During Production

We run tight quality checks while making the parts. We pull parts for checks often during the process. We test their size, look, and strength. This ensures every batch of cast copper parts is consistent and meets your needs.

Final Product Quality Inspection

We use multiple inspectors for the final check. They do many tests on the finished product. These tests cover size accuracy, surface quality, and part strength. This step makes sure all cast copper parts meet your quality standards.

Packaging and Delivery

We securely package and ship all approved parts. We pick the right packaging to prevent damage during shipping. We also choose the best delivery method (air, sea, or land) to get your parts to you on time.

To order custom parts, please email us your design drawings and 3D models. Our team will review the detailed part parameters and the 3D model to provide you with an accurate quote.