Custom Metal Parts For Electrical & Lighting

Custom metal parts for lighting and electrical gear use top materials. We choose aluminum, steel, and copper alloys. These metals must conduct power well, resist rust, and be very strong. This ensures energy moves efficiently. It protects the components from weather and guarantees long life. They are key for streetlights, industrial lamps, and large electrical systems. We use casting, forging, and machining to make these parts. This custom work ensures the best performance, reliability, and cost for the electrical industry.

Electrical & Lighting Parts Classification

1.Lighting Fixtures

Lighting fixtures need to be precise and durable for homes and industrial areas. Castings are often used for detailed housings and bases. This ensures structural stability and good looks. Forgings are used for high-strength parts. These include lamp posts and mounting brackets. Forging ensures they resist outside stress and perform well for a long time.

Castings: Lighting housings, Lamp bases, Reflector assemblies

Forgings: Lamp posts, Mounting brackets, Structural supports

2.Electrical Enclosures

Electrical enclosures protect important electrical components. These include circuit breakers, switches, and control panels. Castings are used to make the complex shapes of these enclosures. This gives them a robust structure and protects them from the environment. Forgings are used for parts that handle dynamic loads and ensure safe connections. These include terminal blocks and busbar supports.

Castings: Enclosure housings, Junction box covers, Panel bases

Forgings: Terminal blocks, Busbar supports, Switchgear components

3.Switchgear and Circuit Protection

Switchgear and protection systems control circuits and guard them from faults and overloads. Castings are typically used for the housing and structural components. This helps with heat dissipation and offers good protection. Forgings are key for high-strength parts. These include circuit breaker contacts, busbars, and connectors. Forging ensures reliability in high-voltage uses and minimizes wear.

Castings: Circuit breaker housings, Distribution board enclosures, Fuse holders

Forgings: Circuit breaker contacts, Busbars, Disconnect switches

4.Connectors and Terminals

Electrical connectors and terminals are key to safe, secure wiring systems. Castings often create complex shapes for connector housings and terminal blocks. These parts need specific electrical and mechanical traits. Forgings are used for high-precision parts that must handle high electrical currents. These include power connectors, pin connectors, and grounding terminals.

Castings: Connector housings, Terminal blocks, Cable connectors

Forgings: Power connectors, Pin connectors, Grounding terminals

5.Power Distribution Components

Power distribution systems need durable parts to safely move electricity to users. Castings are used for parts that house electrical gear, such as transformer housings, busbar enclosures, and distribution boxes. This ensures efficient operation.

Forgings are used for parts that handle large currents and mechanical stress. These include bushing assemblies, power connectors, and heavy-duty mounting brackets. Forging ensures high strength and reliability.

Castings: Transformer housings, Busbar enclosures, Distribution boxes

Forgings: Bushing assemblies, Power connectors, Mounting brackets

6.Electrical Motor Components

Motors need parts that can handle fast turning speeds, mechanical stress, and heat changes. Castings are often used for parts like motor housings, bearing seats, and end bells. These components need complex shapes and strong structural integrity. Forgings are used for high-strength, high-performance parts. These include rotor shafts, bearing races, and gears. Forging ensures precise size limits and resistance to fatigue.

Castings: Motor housings, Bearing seats, End bells

Forgings: Rotor shafts, Bearing races, Gears

7.Street and Industrial Lighting Poles

Street lighting poles must withstand tough outdoor weather. They must also provide a safe, stable base for the lights. Castings are used for the pole bases and decorative elements. Casting offers great rust resistance and is easy to make. Forgings are used for high-strength parts like support arms and mounting brackets. Forging ensures the poles stay stable under heavy winds and other strong forces.

Castings: Pole bases, Decorative elements, Mounting rings

Forgings: Support arms, Mounting brackets, Reinforced connectors

Available Materials For Electrical & Lighting Parts

Cast Iron in Electrical Equipment and Lighting

In the electrical and lighting fields, cast iron makes housings and support parts. It offers high rigidity and is great at absorbing vibrations. We often use sand casting, lost foam casting, and machining to get complex shapes and stable sizes.

Gray Cast Iron:

Uses: Sand-casted for motor bases, transformer housings, and equipment support frames.

Benefit: Its excellent vibration absorption cuts down on operating noise and mechanical shaking.

Ductile Iron:

Features: Achieved through casting and heat treatment for high strength and toughness.

Uses: Suitable for switchgear brackets, distribution box bases, and high-strength mounting brackets. It stays stable during operations like opening/closing and vibration.

Alloy Cast Iron:

Features: Often alloyed and heat-treated to fight heat and wear.

Uses: Used for high-temperature switchgear parts and heavily worn electrical transmission components.

Steel in Electrical Equipment and Lighting

Steel is made into parts that bear loads, transfer power, and offer protection. We use forging, casting, cold rolling, and heat treatment. This ensures long-term reliability for all electrical equipment.

Carbon Steel:

Uses: Often forged or machined into fasteners, guide rails, brackets, and motor shafts.

Benefit: It handles the torque and loads that occur during installation and operation.

Low-Alloy Steel:

Uses: Often forged or welded into heavy-duty circuit breaker supports and busbar clamps.

Benefit: It offers excellent fatigue resistance and is safe for long-term use while live (under power).

Cast Steel:

Uses: Commonly cast for motor end covers, pump bodies, and switchgear housings.

Benefit: Machining afterwards ensures the parts fit precisely and seal well.

Stainless Steel:

Uses: Made into outdoor lighting housings, control cabinets, fasteners, and pipe fittings.

Benefit: It stays stable and strong in humid and corrosive environments.

Aluminum Alloys in Electrical Equipment and Lighting

Aluminum alloys are used to make housings, brackets, and heat sinks. We use die-casting, extrusion, welding, and machining. Aluminum provides a good mix of light weight, heat dissipation, and rust resistance.

Aluminum-Silicon Alloys:

Uses: Commonly made by die-casting for lamp housings, heat sinks, and motor casings.

Benefit: They ensure excellent heat transfer and highly accurate sizes.

Aluminum-Magnesium Alloys:

Uses: Used for outdoor light poles, light fixtures, and electrical enclosures through extrusion and welding.

Benefit: They offer superior corrosion resistance, especially outside.

High-Strength Aluminum Alloys:

Features: Strengthened by special heat treatments.

Uses: Machined into load-bearing frames and busbar duct enclosures. They provide the necessary strength while staying light.

Extruded Profiles:

Uses: Cut and processed into heat sinks, guide rails, and profiled enclosures to fit various assembly needs.

Benefit: They can be anodized for better wear resistance.

Other Metal Alloys in Electrical Equipment and Lighting

These specialty metals are used when the job requires top electrical conductivity, corrosion defense, wear resistance, or high-temperature strength. We use casting, forging, or machining to ensure precision and top performance.

Copper and Copper Alloys:

Uses: Extruded or forged into busbars, terminals, contacts, and slip rings.

Benefit: Ensures excellent electrical conductivity.

Bronze:

Cast or machined into bushings, worm gears, and plain bearings. It resists wear and seizing for smooth operation.

Brass:

Easy to cut and used for pipe fittings, valve bodies, and nuts. It resists rust and is simple to assemble.

Magnesium Alloys:

Uses: Die-cast to create lightweight housings and heat sinks.

Benefit: Greatly reduces the weight of portable electrical devices.

Nickel and Nickel Alloys:

Uses: Often rolled or cast for heating elements, terminals, and high-temperature parts.

Benefit: Ensures long-term, stable operation in harsh conditions.

How To Customize Electrical & Lighting Parts

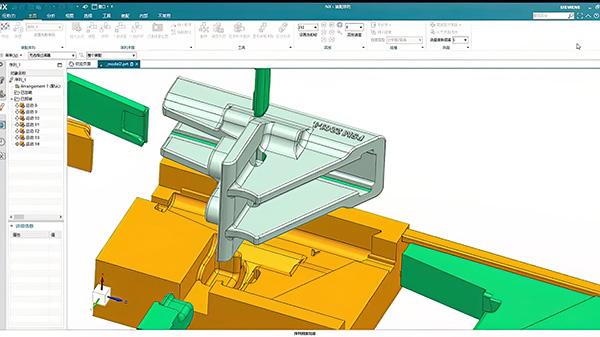

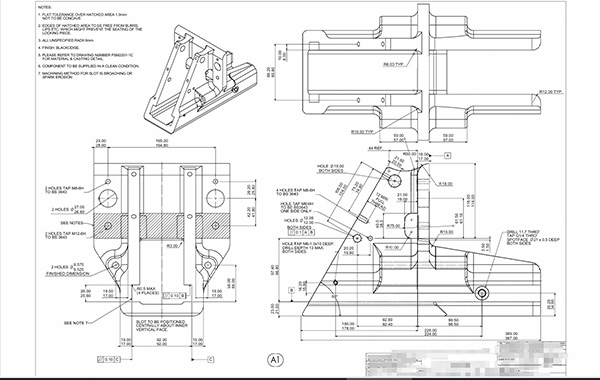

3D Drawings

Processing Drawings

Sample

1. Design Review and Initial Samples

2. Confirm Details: Material, Process, and Performance

3. Make Molds and Samples

4. Comprehensive Sample Inspection

5. Mass Production

6. Post-Production Quality Checks

Custom Processing Of Electrical & Lighting Parts

Casting Electrical Equipment and Lighting Parts

In the electrical and lighting industry, casting makes parts like lampshades, electrical housings, and transformers. These components must handle high electrical loads and effectively dissipate heat. This casting process helps ensure the long life and safety of the electrical equipment and lighting systems.

Forging Electrical Equipment and Lighting Parts

In electrical equipment and lighting, forging creates strong components. These include connectors, switchgear parts, and structural frames. Forging boosts their mechanical strength, conductivity, and durability. This is vital when parts face high loads or frequent use.

Heat Treatment

In the electrical and lighting industries, heat treatment boosts the performance and durability of key parts. This includes electrical contacts, switch assemblies, and power connectors. Heat treatment improves the material's resistance to wear, corrosion, and electrical arcing. This process helps extend the life of critical components that face frequent use and environmental stress.

Machining

In electrical equipment and lighting, machining makes precise components. These include electrical connectors, terminals, and heat sinks. The precision from machining ensures these parts meet strict electrical and mechanical size limits (tolerances). This is vital for the efficient and safe operation of lighting systems, circuit boards, and other electrical gear.

Sheet Metal Fabrication

In the electrical and lighting sector, sheet metal fabrication makes lightweight, durable components. These include electrical enclosures, light brackets, and heat shields. This process protects electrical systems from outside elements. It also improves thermal management and gives structural support to lighting and power distribution gear.

Surface Treatment

In electrical equipment and lighting, surface treatment improves parts in three key ways: it boosts corrosion resistance, reduces electrical resistance, and enhances the look (aesthetics). For example, aluminum housings for lights and electrical boxes are often anodized to stop rust. Meanwhile, electrical contacts may be plated with silver or gold. This ensures reliable conductivity and cuts down on wear over time.