Custom Metal Parts For Municipal Engineering

Custom casting or forging metal parts are essential for modern municipal construction. They enhance the structure, safety, and function of city projects like roads, bridges, public buildings, and utilities. We tailor these parts—such as manhole covers, drain pipes, beams, and guardrails—to meet the exact needs of your project. This customization ensures the parts can handle heavy loads, tough environmental conditions, and long-term wear. We focus on precise size, shape, strength, and corrosion resistance. By using custom, high-quality metal, we not only improve technical performance and look but also boost sustainability and save costs by minimizing future maintenance.

Municipal Engineering Parts Classification

1.Structural Components

Structural parts are key for making city buildings, bridges, and roads strong. They give these structures stability.Castings are often used for shapes that are complex or have many details. This includes supports and brackets. Casting is easy to do and gives stable parts.Forgings are for parts that carry a lot of weight. They must handle stress often. Forging makes them much stronger. This stops them from breaking or changing shape easily.

Castings: Beam supports, Structural brackets, Foundation bases

Forgings: Column bases, High-strength beams, Structural anchors

2.Utility and Infrastructure Components

City projects often need strong parts for important services. These services include water, sewage, and power systems.Castings are common for things like manhole covers, valve housings, and pipe fittings. Castings last a long time and resist rust. This durability is very important.Forgings are used for harder jobs. They are used for pipe connectors and high-pressure valve stems. Forgings are built to handle extreme conditions. They give reliable service for many years in critical systems.

Castings: Manhole covers, Water valve housings, Drainage grates

Forgings: Pipe connectors, Valve stems, Pressure fittings

3.Road and Highway Components

Road and highway parts must handle heavy traffic and bad weather. Castings are often used for simpler parts like road signs and pavement markers. Castings are chosen because they are cheap to make and easy to produce.Forgings are used for critical parts that take high impact and stress. This includes road barriers and guardrails. Forgings ensure strong, long-lasting performance under tough conditions.

Castings: Road sign posts, Traffic barrier supports, Pavement markers

Forgings: Road barrier sections, Guardrail posts, Heavy-duty connectors

4.Drainage and Stormwater Management

Good drainage is key for city projects. It stops floods and keeps infrastructure safe. Castings resist rust and wear. They are used for pipes, culverts, and water catch basins. Forgings are for specialized, heavy-duty parts like pipe joints. Forgings make sure seals are strong. They also improve water flow capacity.

Castings: Drainage pipes, Catch basins, Culverts

Forgings: Pipe joints, Stormwater connectors, Reinforced drain covers

5.Bridge Components

Bridge parts must handle heavy traffic, weather stress, and constant forces. Castings are used for supports, joints, and devices. Castings are chosen for their complex shapes and ability to resist rust.Forgings are used for structural parts like beams and pins. Forgings ensure the bridge is strong and lasts a long time, even in extreme conditions.

Castings: Deck supports, Expansion joints, Bridge bearings

Forgings : Bridge beams, Pin connectors, High-strength linkages

6.Transportation Equipment

City projects often need special machines. These include cranes, trucks, and lifts. Castings are common for machine bodies, supports, and structural frames. Castings are used when strength and stable structure are needed.Forgings are used for parts under high stress. This includes hooks, gears, and shafts. Forgings are critical where high precision and strong load-bearing capacity are needed.

Castings: Machinery housings, Crane supports, Lift bases

Forgings: Lifting hooks, Gear shafts, Axles

7.Signaling and Safety Components

In city projects, safety is key. Parts like traffic lights and safety barriers keep the public safe. Castings are used for things like housings, mounts, and covers. Castings are easy to make and resist bad weather well.Forgings are used for high-strength parts. This includes barrier sections and impact-resistant fittings. Forgings must be strong and resist high impact.

Castings: Signal housings, Traffic light mounts, Safety posts

Forgings: Emergency barrier sections, Impact-resistant connectors, Reinforced posts

Available Materials For Municipal Engineering Parts

Cast Iron in Municipal Engineering

Cast iron is widely used for load-bearing structures, wear-resistant parts, and vibration-absorbing components. This includes municipal projects and heavy machinery. Casting and heat treatment form complex shapes while keeping the material strong and stable.

Gray Cast Iron

Gray cast iron absorbs vibration well and resists pressure. It is good for things like gearbox housings, bridge supports, and manhole covers. It lessens shock and protects machines under heavy loads.

Gray cast iron parts in municipal engineering: Gearbox housings, Bridge supports, Conveyor rollers, Manhole covers

Ductile Iron

Ductile iron is both strong and tough. It works well for pump housings, wheel hubs, bridge supports, and heavy load structures. Its impact resistance keeps equipment stable during shocks and heavy use.

Ductile iron parts in municipal engineering: Hydraulic pump housings, Wheel hubs, Bridge supports, Load-bearing structures

Alloy Cast Iron

Alloy cast iron resists wear and heat. It is used in crusher shafts, wear bushings, and high-friction parts. It also works in cement mill liners. It lasts a long time in high-wear and hot places.

Alloy cast iron parts in municipal engineering: Crusher cutter shafts, Wear bushings, High-friction parts, Cement mill liners

Steel in Municipal and Engineering

Steel is key for city projects, bridges, and heavy machines. Steel parts are forged, cast, and treated to resist loads, wear, and impact. These parts handle high loads, frequent shake, and long use in tough places.

Carbon Steel

Carbon steel is strong and tough. It is good for drive shafts, rods, gears, and machine shafts. It resists the strong impact and torque of heavy machine work.

Carbon steel parts in municipal engineering: Drive shafts, Connecting rods, Hydraulic rods, Gears

Low-Alloy Steel

Low-alloy steel fights wear and resists fatigue well. It is used to make pump housings, brackets, and bridge parts that carry heavy loads. It keeps structures stable under continuous, heavy use.

Low-alloy steel parts in municipal engineering: Hydraulic pump housings, High-stress connectors, Bridge load-bearing parts

Cast Steel

Cast steel is easy to shape. It is used for hydraulic cylinders, pump bodies, and large chassis frames. Cast parts are precise and strong. They work well in complex bridge and machine environments.

Cast steel parts in municipal engineering: Hydraulic cylinders, Pump bodies, Transmission housings, Large chassis

High-Manganese Steel

High-manganese steel fights wear and impact. It is used in bucket teeth, track shoes, and crusher rollers. It stays strong even with sand, gravel, and heavy soil impact.

High-manganese steel parts in municipal engineering: Bucket teeth, Track shoes, Crusher rollers, Pump impellers

Stainless Steel

Stainless steel resists rust and chemicals strongly. It is used for valves, pumps, fasteners, and pipe fittings. It keeps working well even in wet, rainy, or rusty places.

Stainless steel parts in municipal engineering: Hydraulic valves, Pumps, Fasteners, Pipe fittings

Aluminum Alloys in Municipal and Engineering

Aluminum alloys are used in many parts for construction and heavy machines. They are chosen because they are lightweight and resist rust. Casting, welding, and machining aluminum parts lowers the total weight but keeps the strength high.

In city and bridge building, aluminum parts help machines use less energy. They also last longer and cost less to fix, thanks to rust-proof finishes.

Aluminum-Silicon Alloys

These alloys cast well and resist wear. They are good for pump bodies, valve bodies, and gear housings. They make parts lighter and help heat leave quickly.

Aluminum-silicon alloys parts in municipal engineering: Pump bodies, Valve bodies, Gearbox housings, Support brackets

Aluminum-Magnesium Alloys

These alloys resist rust and are very light. They are often used for body panels, handrails, and ladders. They are great for outdoor and wet places.

Aluminum-magnesium alloys parts in municipal engineering: Body panels, Handrails, Ladders, Exterior protective components

High-Strength Aluminum Alloys

These alloys are nearly as strong as soft steel. They can be used for heavy load frames, booms, and strong connectors. Heat treatment makes sure these parts can carry heavy loads.

High-strength aluminum alloys parts in municipal engineering: Load-bearing frames, Booms, High-stress connectors

Aluminum Sheets and Profiles

After treatment, the surface of these sheets resists wear and rust. They are often used for platforms, channel plates, and non-slip steps. They are easy to set up and take care of.

Aluminum Sheets and Profiles parts in municipal engineering: Platform plates, Channel plates, Non-slip pedals, Building formwork

Other Metal Alloys in Engineering

Many specialty metal alloys are used in city building and heavy machines. They meet special needs like fighting rust, wear, and high heat.

Copper Alloys

Copper alloys are great conductors of electricity and resist rust well. They are often used for electric terminals, slip rings, and wear-resistant bushings. Casting or machining gives them high accuracy and a long life.

Copper alloys parts in municipal engineering: Electrical terminals, Slip rings, Hydraulic valve cores, Wear-resistant bushings

Bronze

Bronze fights wear and binding. It is used in bushings, worm gears, and plain bearings. This ensures heavy construction equipment runs smoothly under big loads.

Bronze parts in municipal engineering: Bushings, Worm gears, Plain bearings, Guides

Brass

Brass is easy to cut and seals well. This makes it good for sealing parts like pipe fittings, valve bodies, and nuts. It resists moisture and corrosive liquids.

Brass parts in municipal engineering: Pipe fittings, Valve bodies, Nuts, Fastening components

Titanium Alloys

Titanium alloys are light, very strong, and resist rust. They are used for high-end bridge cables, fasteners, and special machine parts. Forging makes them very strong and reliable.

Titanium alloys parts in municipal engineering: Bridge cables, Fasteners, Specialized engineering components

Heat-Resistant Alloys

These alloys stay stable even in very hot places. They are used for gas turbine parts, exhaust systems, and high-temperature seals. This keeps power systems working safely.

Heat-resistant alloys parts in municipal engineering: Gas turbine components, Exhaust systems, High-temperature seals

How To Customize Municipal Engineering Parts

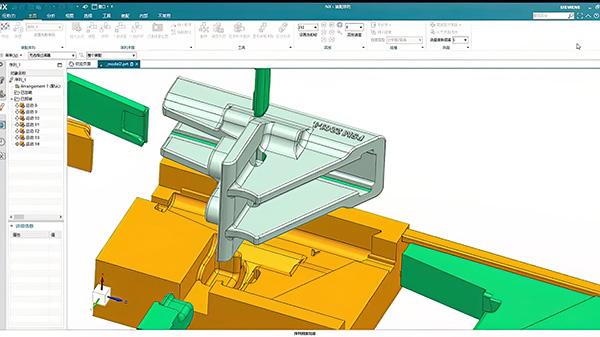

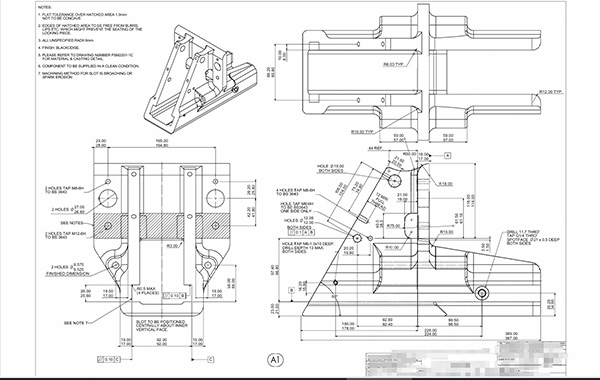

3D Drawings

Processing Drawings

Sample

1. Provide Design Documents or Samples

2. Confirm Material, Process, and Performance

3. Make Molds and Samples

4. Comprehensive Sample Inspection

5. Mass Production

6. Post-Production Quality Inspections

Custom Processing of Construction Engineering Parts

Casting Municipal Construction Parts

Casting processes are used to make strong and complex parts for city engineering. Examples include manhole covers, drain pipes, bridge parts, and structural bases. These parts must handle heavy loads, bad weather, and constant wear. Casting ensures the durability and strong structure of city buildings and roads.

Forging Municipal Construction Parts

Forging processes make strong parts for city projects. They produce items like rebar, brackets, joints, and fasteners. These are used in large infrastructure work. Forged parts have great fatigue resistance and strength. This makes them perfect for high-stress uses in bridges, buildings, and roads.

Heat Treatment

Heat treatment is used for parts in city projects. This includes steel beams, rebars, and structural items. The goal is to make them stronger and better at fighting rust. This also makes them last longer. This process extends the life of key structures like bridges, tunnels, and tall buildings.

Machining in Municipal Construction

Machining is used to make parts for city projects. This includes concrete molds, steel beams, and custom structural items. Machining gives parts very high precision. This ensures that key structures like roads, bridges, and tunnels run smoothly and stay stable.

Sheet Metal Fabrication

Sheet metal is used to make parts for city projects. This process makes components that are lightweight and durable. This includes roof panels, facades, and wall systems. These parts make public buildings and bridges strong and look good. Sheet metal allows for fast building and easy custom design.

Surface Treatment

Surface treatment is used for parts in city projects. This includes steel bars, pipes, and metal facades. The goal is to protect these parts from rust and weather damage. This treatment makes materials last longer and work better in city projects. It ensures parts can handle bad weather, traffic, and environmental stress for a long time.