Custom Pedal Manufacturer

Pedal

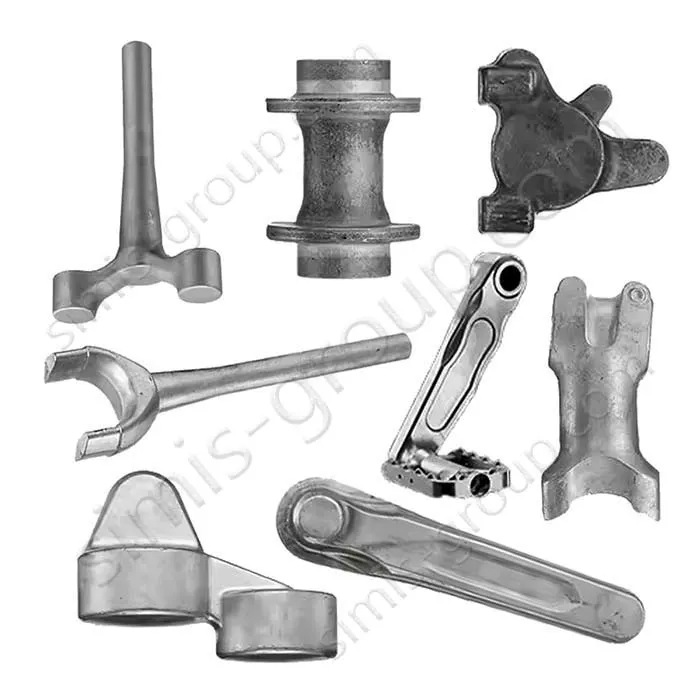

China Simis Company is an experienced OEM custom manufacturer of Casting and Forging Pedals (including brake, clutch, accelerator pedals, and high-strength footrests) for a vastly diverse range of industries, including safety-critical automotive controls (clutch, brake, accelerator), high-performance cycling, and heavy-duty industrial machinery. Failure in a pedal component is unacceptable, making structural integrity, fatigue life, and high impact resistance paramount.

We leverage Precision Forging for performance and safety-critical applications using Alloy Steel, Carbon Steel, and Aluminum Alloy. We utilize diverse Casting methods (including Investment Casting for stainless steel and Sand Casting or Shell Mold Casting for complex ductile iron) to manufacture components from Ductile Iron, Carbon Steel, and Stainless Steel for high-volume, cost-effective, or complex industrial solutions. Our processes ensure full compliance with regulatory safety standards (e.g., automotive FMVSS) through rigorous material control and testing.

What Manufacturing Processes Are Optimized for Safety-Critical and Load-Bearing Pedals?

We select the optimal manufacturing process based on the required strength, geometric complexity, and the specific safety factor demanded by the pedal application. Each process is matched to component function to ensure maximum structural integrity and service life in target working environments.

| Manufacturing Process | Component Focus | Material Focus | Key Advantage for Pedal Performance |

| Precision Closed Die Forging | Automotive (Racing Brake/Clutch Pedals), High-Stress Linkages. | Alloy Steel, Carbon Steel, Aluminum Alloy. | Mandatory for Safety-Critical Components. Maximizes fatigue life and yield strength for high-leverage and high-stress points. |

| Cold Forging | Bicycle Spindles, Crank Arms, Small Bushings, Pedal Pins. | Alloy Steel, Carbon Steel. | Superior Dimensional Precision and Surface Finish. Essential for high-volume, highly accurate small components requiring maximum strength. |

| Pressure Die Casting | Accelerator Pedals, Aluminum Pedal Bodies, Housings. | Aluminum Alloy, Zinc Alloy. | Lightweighting and High Volume. Achieves excellent surface finish and complex internal coring for sensors. |

| Sand Casting | Largest Industrial Machine Pedals, Very Heavy-Duty Foot Controls. | Ductile Iron, Gray Iron, Carbon Steel. | Traditional & Flexible. Most cost-effective method for very large and massive industrial pedal bodies, excellent for vibration damping. |

| Shell Mold Casting | Medium-Sized Industrial Pedals, Consistent Cast Brackets. | Ductile Iron, Carbon Steel. | Improved Surface Finish & Dimensional Consistency. Better than sand casting for complex features and consistent quality in medium volumes. |

| Precision Investment Casting (Lost Wax) | Small Precision Pedals, Stainless Steel Marine Components. | Stainless Steel, Alloy Steel. | High Precision, Excellent Surface Finish for intricate parts requiring superior corrosion and chemical resistance. |

| Sheet Metal Fabrication | Stamped Pedal Arms, Linkage Plates, Clutch Assemblies. | Carbon Steel, Stainless Steel. | Cost and Weight Efficiency. Ideal for high-volume, low-to-medium stress components via stamping and welding. |

| Precision CNC Machining | Spindle Threading, Mounting Bosses, Pin Interfaces, Sensor seats. | All Materials. | Essential for precise alignment, smooth hinge movement, and achieving the critical thread tolerances (H7/IT7). |

How to Select the Right Material for Casting and Forging Pedals?

Material selection balances strength/toughness (for impact and fatigue) with weight and environmental demands (corrosion). Each material grade is chosen to match the specific mechanical and environmental stressors of the target pedal application.

| Material Type | Core Performance Attributes | Typical Pedal Application & Service |

| Alloy Steel | Ultimate Tensile Strength; superior fatigue and wear resistance (achieved via Closed Die Forging). | Brake and Clutch Pedals for heavy vehicles and high-performance bikes. |

| Carbon Steel | High ductility and reliable strength | Standard Automotive Pedals, linkage assemblies, and structural footrests, Cast or Forged General Industrial Pedals, E-Bike Pedal Spindles. |

| Aluminum Alloy | Extreme Lightweighting; Highest Strength-to-Weight Ratio (achieved via Forging) or low inertia (via Die Casting). | Bicycle Cranks/Pedal Bodies (Forged), Accelerator Pedals (Die Cast), Forged Racing/Performance Bicycle Pedals, E-Bike Platform Bodies. |

| Ductile Iron | High Strength & Shock Resistance; good castability. | Heavy Industrial Machine Pedals and robust foot controls, Tractor Clutches. (via Sand Casting / Shell Mold Casting). |

| Gray Iron | Excellent Vibration Damping and high compressive strength. | Industrial Footrests and static mounting platforms where vibration mitigation is critical. |

| Stainless Steel | Superior Corrosion Resistance; high hygiene compliance. | Marine/Offshore Equipment Pedals, food processing equipment foot controls, Outdoor Construction Machinery. (via Investment Casting). |

What Quality Assurance and Regulatory Compliance Apply to Casting and Forging Pedals?

Compliance with safety standards is the top priority for pedal manufacturing, particularly in the transportation and industrial sectors. Our quality control protocols are designed to eliminate potential failure points and ensure full adherence to industry-specific safety regulations.

·Fatigue Testing:

Mandatory cyclical load testing (compression and tension) is performed to simulate the lifetime of repeated use, ensuring the pedal exceeds safety factors (critical for automotive/bicycle components).

·Impact Testing:

Pedals for construction and agricultural machinery are subjected to specific Impact Testing to verify resistance against sudden, heavy loads or foreign object strikes.

·NDT (Non-Destructive Testing):

MPI (Magnetic Particle Inspection) or LPI (Liquid Penetrant Inspection) is performed on forged safety-critical components to ensure freedom from surface or near-surface fatigue initiators.

·Dimensional and Tolerance Control:

CMM verification confirms the precise geometry of hinge points, mounting holes, and critical threads to ensure perfect fit and fail-safe operation.

What Are the Key Application Sectors for Casting and Forging Pedals?

We serve sectors ranging from heavy industry to personal mobility, utilizing specialized processes for each Pedal type. Our pedal solutions are engineered to meet the unique performance and safety requirements of each industry vertical.

| Application Sector | Typical Pedal Component | Simis Process Focus |

| Automotive OEM | Brake, Clutch, Accelerator Assemblies | Closed Die Forging (Brake Pedals), Sheet Metal Fabrication, Pressure Die Casting. |

| Heavy Machinery | Foot Controls, Safety Locking Pedals (Excavators, Loaders). | Sand Casting (Ductile Iron), Closed Die Forging (High-stress components). |

| Motorcycle & E-Bike | Rider/Pillion Footrests, Shift Pedals, Kick Starters. | Closed Die Forging (Alloy Steel), Pressure Die Casting (Aluminum Housings). |

| Bicycle & Fitness | Pedal Spindles, Crank Arms, Pedal Bodies. | Cold Forging (Spindles/Crank Arms), Pressure Die Casting (Aluminum Body). |

What Are the Advantages of Simis OEM Custom Manufacturing for Casting and Forging Pedals?

Our expertise across casting and forging allows us to meet the stringent requirements of diverse pedal applications, from delicate controls to heavy machinery. We combine process versatility with quality rigor to deliver pedals that exceed industry safety and performance benchmarks.

·Certified Safety Focus:

We understand that pedals are safety-critical. We prioritize the use of Forging and stringent NDT to maximize the structural integrity and fatigue life of components in cars, motorcycles, and high-performance bikes.

·Broad Material/Process Range:

We provide material solutions from Lightweight Forged Aluminum (for racing weight savings) to Heavy-Duty Cast Ductile Iron (for industrial durability and cost-effectiveness), leveraging Closed Die Forging and Pressure Die Casting for optimal efficiency.

·Compliance Expertise:

We possess the capability to manufacture and certify components to specific industry regulations, including relevant automotive FMVSS standards and ISO testing protocols.

·Precision Interface Machining:

We guarantee the precision of all interfaces, particularly the critical threading and hinge bores, ensuring reliable function and ease of assembly.

How to Get a Quote for Custom Casting & Forging Pedals?

China Simis Company is your expert global partner for custom casting and forging pedals, engineered for safety-critical reliability, superior fatigue resistance, and multi-industry durability. To obtain a detailed, accurate quotation for your custom pedal project, please provide the following technical documentation and specifications to our professional engineering team:

2D technical drawings or 3D CAD models with complete dimensional tolerances (including hinge bore precision, thread class, and surface finish requirements)

Detailed pedal application information: target industry (automotive, bicycle, heavy machinery), load rating, and operational environment (corrosive, high-vibration, high-cycle)

Required material grade and heat treatment specifications (e.g., Alloy Steel 4140 quenched & tempered, Aluminum Alloy 6061-T6)

Regulatory compliance requirements (e.g., FMVSS 135 for automotive brakes, ISO 4210 for bicycle components)

Annual production volume, delivery timeline, packaging requirements, and target shipping destination

Our engineering team will conduct a comprehensive feasibility analysis, provide material and process optimization recommendations, and deliver a full quotation package covering unit pricing, tooling costs, production lead time, quality inspection plans and global logistics solutions.