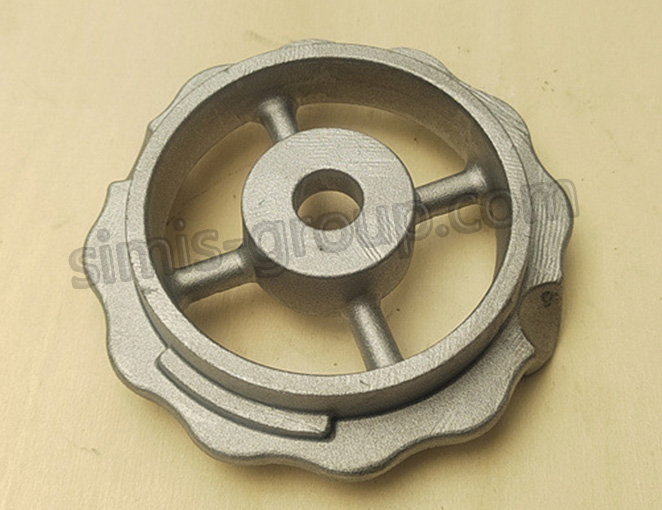

Custom Hand Wheels Manufacturer

Hand Wheels

China Simis Company is a manufacturer of casting high-quality Hand wheels used extensively in valve operations, machine tool controls, and precision adjustment systems. Hand wheel is more than just a handle; it is the critical human-machine interface requiring a perfect balance of structural strength, corrosion resistance, and ergonomic comfort.

We offer a comprehensive range of solutions across five core manufacturing processes. From Sand Casting heavy-duty Ductile Iron hand wheels for industrial valves to Stainless Steel investment casting hand wheels for the pharmaceutical industry, and high-density Aluminum Gravity Die Casting hand wheels for high-torque mechanical adjustments. Simis selects the optimal material and process based on your torque requirements and operating environment.

What Manufacturing Processes Are Used for Hand Wheels?

The choice of casting process for hand wheels depends on factors such as customer requirements for materials, usage scenarios, and cost constraints.

| Manufacturing Process | Primary Application | Core Materials | Key Engineering Advantage |

| Sand Casting | Large industrial valves, heavy machinery. | Ductile Iron / Gray Iron. | Maximum Torque. Ideal for large-diameter wheels; cost-effective and extremely robust for heavy-duty operation. |

| Gravity Die Casting | High-strength mechanical hand wheels, medium volumes. | Aluminum Alloy (A356/A357). | Structural Integrity. Lower porosity than die casting; supports T6 heat treatment for significantly higher mechanical strength. |

| Die Casting | Lab equipment, light machinery, high-volume electronics. | Aluminum Alloy (A380). | Lightweight & High Speed. Superior dimensional accuracy for intricate designs; most economical for large-scale production. |

| Silica Sol Investment Casting | Food, medical, and marine equipment. | Stainless Steel (304/316). | Superior Surface Finish. Non-porous and smooth surfaces that are easy to sanitize and highly resistant to chemicals. |

| Metal Pressing / Stamping | Standard commercial valves, hardware. | Carbon Steel / Stainless Steel. | Production Efficiency. The most cost-effective solution for mass-produced, thin-walled, yet durable standardized wheels. |

How to Select Materials for Hand Wheels?

We strictly adhere to international material grades to ensure reliability in diverse environments:

| Material Type | International Standards | Performance Attributes | Typical Application |

| Ductile Iron | ASTM A536 65-45-12 | QT450-10. | Exceptional ductility and impact strength; resistant to brittle failure under high torque. | High-pressure gate valves, oilfield pipelines. |

| Gray Iron | ASTM A48 Class 35 | HT250. | Excellent cost-efficiency, vibration damping, and wear resistance. | General industrial valves, base machinery. |

| Aluminum Alloy | ASTM B108 A356.0 | ASTM A380. | High strength-to-weight ratio; anti-oxidation and excellent aesthetic finishing. | Industrial cranks, machine tool controls, laboratory gear. |

| Stainless Steel | ASTM A351 CF8M (316) / CF8 (304). | Outstanding rust prevention; resistant to acids, alkalis, and saltwater. | Chemical, pharmaceutical, offshore platforms. |

| Carbon Steel | AISI 1020 / 1045. | Reliable structural integrity; used primarily for high-speed stamping and pressing. | Standard hardware, water treatment facilities. |

What Quality Control & Precision Testing Are Applied to Hand Wheels?

·Torque Load Test:

Verifies the strength of the spoke-to-hub connection to ensure no failure during emergency high-torque operations.

·Concentricity Check:

Ensures the central bore is perfectly aligned with the outer rim to prevent "wobbling" during rotation.

·NDT Inspection:

X-ray or Ultrasonic testing available for high-load Gravity Cast or Sand Cast wheels to ensure zero internal defects.

·Surface Finish Audit:

100% manual inspection to ensure no sharp casting flash or burrs remain on the gripping rim.

What Are the Key Application Areas for Hand Wheels?

| Industry & Application | Specific Component Use | Recommended Material & Process |

| Industrial Valves | Gate, Globe, and Ball valves for flow control. | Ductile Iron (Sand Casting). High torque resistance for manual seating and unseating of valve discs. |

| Pipeline Infrastructure | Mainline isolation valves, pumping stations. | Gray Iron (Sand Casting). Cost-effective for large-diameter wheels with excellent vibration damping. |

| Oil & Gas Piping | Oil Christmas trees, manifold valves, and refinery pipelines. | Ductile Iron (QT450) + Epoxy Coating. Built to survive high-pressure surges and harsh outdoor environments. |

| Water & Sewage | Municipal water mains, treatment plant sluice gates. | Stamped Steel or Cast Iron. Durable enough for high-humidity and submerged environments. |

| Chemical & Hygienic Piping | Stainless steel piping for pharmaceutical or food plants. | Stainless Steel (Investment Casting). Mirror-polished finish to prevent bacterial growth and withstand caustic washdowns. |

| HVAC & Fire Protection | Balancing valves, fire hydrant standpipes. | Aluminum (Die Casting or Gravity Die Casting). Lightweight for rapid response and easy identification via red powder coating. |

| Marine | Control components, marine valves, regulating systems, marine ballast systems | Ductile iron, stainless steel, or aluminum alloy. Different materials and processes are selected depending on the application. |

What Are the Advantages of Simis OEM Custom Hand Wheels?

·Versatile Bore Options:

Customizable square holes, round holes with keyways, tapered bores, or threaded holes to fit any valve stem.

·Ergonomic Grip:

Rims can be designed with non-slip grooves, finger-contoured grips, or plastic coatings.

·Brand Identity:

Support for logo casting or laser engraving on the hub or spokes.

·Color Coding:

High-visibility powder coating (Red for Emergency, Blue for Water, Yellow for Gas).

How to Get a Quote for Custom Hand Wheels?

China Simis Company provides the hand wheels your equipment demands. Whether you need the brute strength of Cast Iron, the lightweight precision of Aluminum (Gravity or Die Cast), or the sterile durability of Stainless Steel, we deliver products that meet the highest international standards.

To obtain a detailed and accurate technical quotation for your custom hand wheel project, please submit the following technical documentation and specifications to our professional engineering team:

2D/3D technical drawings or CAD models with complete GD&T (Geometric Dimensioning and Tolerancing) requirements

Specified hand wheel diameter, rim width, and bore configuration (square/round/keyway/tapered/threaded)

Material grade requirements (e.g., ASTM A536 Ductile Iron, 316 Stainless Steel, A356 Aluminum Alloy)

Operating environment details (pressure, temperature, corrosive media, humidity)

Surface treatment and finishing requirements (painting, powder coating, polishing, epoxy coating)

Customization needs (logo engraving, non-slip grip design, color coding)

Annual production volume, target delivery lead time, packaging standards, and shipping destination

Special certification requirements (e.g., ISO 9001, CE, FDA for medical applications)

Our engineering team will conduct a comprehensive Design for Manufacturability (DFM) analysis, optimize the hand wheel structure for maximum torque resistance and ergonomic comfort, and deliver a full quotation package covering unit pricing, tooling costs, quality inspection protocols, and global logistics solutions.