Process Selection for Cast Shafts and Forged Shafts

Shafts, as core components of mechanical transmission systems, have a direct impact on their reliability and service life. According to the 2023 annual report of the International Union of Mechanical Engineers (IMechE), approximately 38% of global industrial shafts are forged, 45% are cast, and the remainder are manufactured using other methods. This distribution reflects the importance of these two processes in modern industry. An analysis of the technical characteristics, microstructural evolution, and mechanical properties of these two primary manufacturing processes reveals that forged shafts maintain their performance advantages in critical power transmission applications, while cast shafts offer significant economic advantages in the production of large, complex structural components.

1. Technical Characteristics of Cast Shafts

1.1 Standardized Production Process for Cast Shafts

Sand Casting:

Typical Tolerances: ISO 8062 CT10-CT13

Surface Roughness: Ra 12.5-25μm (ISO 1302)

Investment Casting:

·Typical Tolerances: ISO 8062 CT6-CT8

Surface Roughness: Ra 3.2-6.3μm

Centrifugal Casting:

Typical Application: Large hollow shafts for the petrochemical industry

| Material Standard | Grade | Tensile Strength (MPa) | Yield Strength (MPa | Elongation (%) | Applicable Processes |

| EN 10293 | G20Mo5 | 500-700 | 300-450 | 18-22 | Sand Casting / Investment Casting |

| ASTM A148 | Grade 80-50 | 550-750 | 350-500 | 15-20 | Sand Casting |

| ISO 3755 | GS-52 | 520-720 | 320-480 | 16-21 | Centrifugal Casting |

| JIS G5101 | SC450 | 450-600 | 250-350 | 20-25 | Sand Casting |

1.2 Microstructural Characteristics of Cast Shafts

Typical casting microstructure evaluated according to ISO 4967:

·Dendrite spacing: 100-300 μm (sand casting)

·Porosity: <2% (in accordance with ISO 10049)

·Non-metallic inclusions: Class B (ISO 4967 rating ≤ 2)

Ultrasonic testing (ISO 11484) of a ship intermediate shaft made of EN 10293 G17CrMo5 material revealed internal defects below 1 mm, fully meeting DNV GL specifications.

2. Technical Characteristics of Forged Shafts

2.1 Standardized Production Process for Forged Shafts

Open Forging:

Typical Tolerances: ISO 286-2 H11-H13

Surface Quality: ISO 8501-1 Sa2.5

Die Forging:

Typical Tolerances: ISO 286-2 H9-H11

Material Utilization: 60-80%

Cold Forging/Warm Forging:

Typical Accuracy: ISO 286-2 H7-H9

Surface Roughness: Ra 0.8-1.6μm

| Material Standard | Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Impact Energy (J) | Applicable Processes |

| ISO 683-1 | 42CrMo4 | 900-1100 | 650-800 | 45-60 | Closed Die Forging/Open-die Forging |

| ASTM A322 | Grade 4140 | 850-1050 | 600-750 | 40-55 | Closed Die Forging |

| EN 10083-3 | 34CrNiMo6 | 1000-1200 | 800-950 | 50-70 | Open-die Forging |

| JIS G4053 | SCM440 | 900-1100 | 650-800 | 45-60 | Cold Forging/Warm Forging |

2.2 Microstructural Advantages of Forged Shafts

Typical forged microstructure evaluated according to ISO 643:

·Grain size: 10-30 μm (better than ASTM E112 grades 7-8)

·Streamline continuity: ISO 3763 rating Class A

·Non-metallic inclusions: Class A (ISO 4967 rating ≤ Class 1)

A wind turbine main shaft uses EN 10083-3 34CrNiMo6 material. Ultrasonic testing (EN 10228-3 standard) shows that the fiber streamlines perfectly conform to the shaft contour, resulting in fatigue life that is over 50% longer than that of a cast part.

3. Performance Comparison of Cast and Forged Shafts

3.1 Mechanical Properties Comparison

| Performance Specifications | Test Standard | Cast Shaft | Forged Shaft | Variation |

| Tensile Strength | ISO 6892-1 | 520-720 MPa | 900-1100 MPa | +55% |

| Yield Strength | ISO 6892-1 | 320-480 MPa | 650-800 MPa | +80% |

| Impact Toughness (20°C) | ISO 148-1 | 25-35 J | 45-60 J | +85% |

| Fatigue Limit (10⁷ Cycles) | ISO 12107 | 220-280 MPa | 400-450 MPa | +75% |

| Hardness | ISO 6506 | 160-220 HB | 250-320 HB | +50% |

3.2 Comparison of Economic Efficiency and Process Adaptability

Cost Structure Analysis:

Material Cost:

·Casting: Low (Material Utilization Rate 85-95%)

·Forging: Medium (Material Utilization Rate 60-80%)

Processing Cost:

·Casting: High (Requires Extensive Machining)

·Forging: Low (Near-Net Shape)

Mold Cost:

·Casting: High (Complex Molds)

·Forging: Medium (Standardized Molds)

Testing Cost:

·Casting: High (Requires Comprehensive NDT)

·Forging: Low (Sampling Testing)

4. International Standard Selection Guide for Shaft Parts

4.1 Selection by Application

| Applications | Recommended Processes | International Material Standards |

| Wind Turbine Main Shaft | Forged | EN 10083-3 34CrNiMo6 |

| Marine Propulsion Shaft | Casting | EN 10293 G20Mo5 |

| Automotive Drive Shaft | Forged | ISO 683-1 42CrMo4 |

| Engineering Machinery Rotary Shaft | Casting | ASTM A148 Grade 80-50 |

| Aircraft Engine Shaft | Forged | AMS 6414 (4340M) |

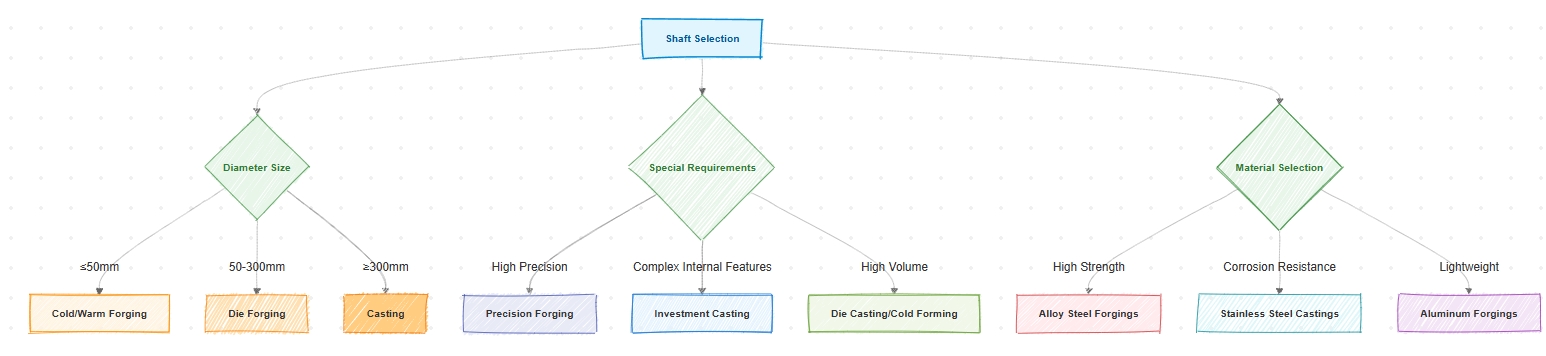

4.2 Selection by Dimensional Parameters

Diameter Selection Guide:

·Small Shafts (Φ < 100mm):

Preferred Process: Cold Forging/Warm Forging

·Medium Shafts (100mm ≤ Φ ≤ 300mm):

Preferred Process: Die Forging

·Large Shafts (Φ > 300mm):

Economical Option: Casting

5. Classification and process selection of shaft parts

(1). Transmission Shafts

· Structural features

Used to transmit torque and rotational motion

Aspect ratio is usually >5:1

Surface usually requires fine machining

· Process adaptability

| Diameter Range (mm) | Recommended Process | International Material Standards | Process Advantages |

| <50 | Cold/Warm Forging | ISO 4954 16MnCr5 | High Precision, Minimized Cutting |

| 50-150 | Die Forging | EN 10083-3 42CrMo4 | Fiber Streamline Optimization |

| >150 | Open Forging + Turning | ASTM A322 4140 | Suitable for Large Sizes |

| Extra Large (>500) | Centrifugal Casting | EN 10293 G20Mo5 | Economical |

(2). Splined Shafts

·Structural Features

With axial spline teeth

Requires precise fit

International standards: ISO 14 (flat root spline), ISO 4156 (involute spline)

·Process selection

Cold forged spline shaft:

Applicable size: diameter <80mm

Material standard: JIS G4053 SCM415

Precision grade: ISO 1328 Class 6-7

Advantage: Tooth surface finish Ra0.8-1.6μm (ISO 1302)

Cutting spline shaft:

Applicable size: diameter 80-250mm

Material standard: ASTM A322 4340

Process route: forging blank → turning → milling spline

Cost analysis: 15-20% lower than full forging

Special process selection:

Large module spline (module > 5): Rolling forming (ISO 1265 standard)

Involute splines: Die forging is preferred (DIN 5480 standard)

(3) Spindles

· Structural features

High speed, high precision

Usually requires heat treatment

· Process selection

| Spindle Type | Typical Dimensions | Recommended Process | Material Standards | Heat Treatment Requirements |

| Machine Tool Spindle | φ50-200mm | Precision Forged | ISO 683-1 / 42CrMo4 | Quenched and Tempered + Case Hardened |

| Motor Spindle | φ20-100mm | Cold Forged | JIS G4805 SUJ2 | Through Hardened |

| Heavy Duty Spindle | >φ300mm | Casting + Machined | EN 10293 G28NiCrMoV7 | Normalized + Tempered |

·Technical Key Points:

Precision spindle roundness requirement: ≤0.005mm

Dynamic balance grade: Typically G1.0

Bearing surface hardness: 58-62 HRC

(4). Crankshafts

· Structural features

Complex crank structure

High fatigue strength requirements

· Process selection

-- Advantages of forged crankshafts:

Process route: die forging → heat treatment → finishing

Fatigue life: >5×10⁶ times (ISO 12107 standard)

-- Application of cast crankshafts:

Large crankshafts (single crank weight >500kg)

Material standard: ASTM A148 Grade 120-90

Process control: 100% ultrasonic testing required (ISO 11484)

-- Innovative process:

Compound casting: chilled cast iron sleeve cast into the journal (ISO 21988 standard)

Surface strengthening: journal rolling (ISO 13565 surface roughness standard)

(5). Camshafts

·Structural features

Precision cam profile

High wear resistance requirements

·Process comparison

-- Casting camshafts:

Main process: Shell casting

Material standard: EN-GJS-700-2 (ductile iron)

Surface treatment: Chilled casting of cam parts

Economic batch: >5000 pieces

-- Forged camshafts:

High-end applications: Racing engines

Material standard: ISO 4951 51CrV4

Process route: Die forging → CNC machining → Nitriding treatment

Precision control: Cam lift error ≤ 0.05mm

-- Assembled camshafts:

Modern trend: Steel tube + sintered cam

Standard basis: ISO 2739 (powder metallurgy standard)

Weight reduction effect: 30-40% lighter than traditional structures

(6). Special shafts

· Hollow Shafts

Process selection:

Small diameter (<100mm): Cold drawn tube + machining (EN 10305-1 standard)

Medium diameter (100-300mm): Centrifugal casting (ISO 4957 standard)

Large diameter (>300mm): Welded structure (ISO 5817 welding standard)

· Eccentric Shafts

Manufacturing difficulty: High dynamic balance requirements

Recommended process: Forging + eccentric turning (ISO 1940-1 balance standard)

Material selection: ISO 683-1 42CrMo4

· Flexible Shafts

Special process:

Multi-layer steel wire winding (ISO 2408 wire rope standard)

Stainless steel material: ASTM A313 304SS

Minimum bending radius: ≥10×shaft diameter

6. Which manufacturing process is best for shafts?

Forged shafts maintain performance advantages in critical powertrain applications and are particularly suitable for high-stress, high-reliability applications.

Cast shafts offer irreplaceable economic advantages in the production of large, complex structural parts, and their performance continues to improve with advances in material technology.

Process selection should comprehensively consider dimensional parameters, load conditions, certification requirements, and cost factors, establishing a full lifecycle cost analysis model.

7.SIMIS Group Custom Shaft Manufacturing Capabilities

SIMIS Group specializes in providing tailored shaft manufacturing solutions to meet diverse global requirements. Our expertise spans the full spectrum of international standards and advanced manufacturing technologies.

7.1 Material Selection Expertise

Carbon/alloy steels: EN 10083, ASTM A322, JIS G4053 series

Stainless steels: ISO 683-13, ASTM A564, EN 10088

Special alloys: Nickel-based (ISO 9723), Titanium (AMS 4928)

Material certification: EN 10204 3.1/3.2 with full traceability

7.2 Flexible Process Portfolio

| Process | Capacity Range | Tolerance Level | Intl. Standards |

| Cold Forging | Ø5-80m | ISO 286 IT7-8 | ISO 4954, DIN 7526 |

| Hot Forging | Ø50-1200mm | ISO 286 IT10-11 | ISO 4885, ASTM A788 |

| Sand Casting | Ø100-2500mm | ISO 8062 CT10-13 | ISO 3755, EN 10293 |

| Investment Casting | Ø20-800mm | ISO 8062 CT6-8 | ASTM A732, EN 10295 |

| Centrifugal Casting | Ø150-1500mm | ISO 8062 CT8-10 | ISO 4957, ASTM A608 |

7.3 Specialized Shaft Manufacturing

Spline Shafts:

Cold formed (Ø<80mm): DIN 5480/ISO 14 compliant

Machined (Ø80-300mm): AGMA 915-1 Class 6-8

Surface finish: Ra 0.4-1.6μm per ISO 1302

Precision Spindles:

Grinding tolerance: ±0.002mm (ISO 286 h5)

Straightness: 0.01mm/m (ISO 1101)

Dynamic balancing: G0.4-G1.0 per ISO 1940-1

7.4 Value-Added Services

Heat treatment:

Annealing, Normalizing, Quenching, Tempering, Q&T, Surface Hardening ...

Surface engineering:

Hard chrome plating (ISO 4520), Nitriding (AMS 2759/10)

Non-destructive testing:

UT (EN 10228-3), MT (ISO 4986), RT (ISO 5579)

Assembly:

Keyway broaching, bearing fitting, dynamic balancing

In industrial manufacturing, the performance of shaft components directly impacts equipment reliability and service life. Whether it's the cost-effectiveness and adaptability of cast shafts to complex structures, or the high strength and fatigue resistance of forged shafts, choosing the right process and materials is crucial.

As a professional manufacturer of shaft components, SIMIS Group has the extensive experience and technical expertise to provide customized solutions tailored to your specific needs. For custom shaft components, whether made of cast steel or forged steel, please contact our engineering team. We will provide comprehensive support from design to mass production, ensuring our products meet the strength, precision, and durability requirements of your application.