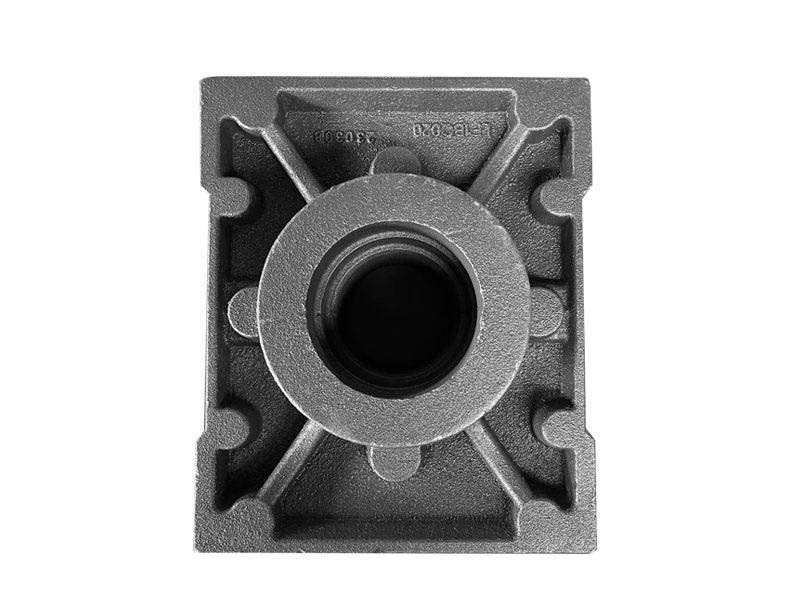

Custom Austempered Ductile Iron Parts Manufacturer

Austempered Ductile Iron Parts

China Simis Company specializes in the manufacturing of Austempered Ductile Iron (ADI) Components. ADI is not simply a casting material but a high-performance engineered material created by applying a precise Austempering heat treatment to standard ductile iron castings. This process transforms the material microstructure into Ausferrite (a combination of high-carbon austenite and bainite).

The resulting ADI component offers an exceptional combination of properties: it possesses the strength and wear resistance rivaling many alloy steel forgings, combined with the excellent toughness and vibration damping inherent to ductile iron. ADI is recognized globally as a cost-effective, lightweight alternative for high-stress applications in heavy industry, which is verified by numerous industrial application cases and metallurgical research results.

1. What Is the Production Process of Simis ADI Parts?

The quality of ADI is determined by the strict control over both the initial casting process (ensuring high-quality ductile iron) and the specialized Austempering heat treatment. Simis has established a complete process control system certified by industry standards to ensure the stability and reliability of each production link.

| Manufacturing Process | Focus/Role | Material Output/Result | Key Advantage for ADI Performance |

| Ductile Iron Casting | Initial Component Formation (Near-Net Shape), with strict control of chemical composition and pouring temperature. | High-Quality Ductile Iron (Spheroidal Graphite) that meets ASTM A536 standards. | Ensures the necessary spherical graphite structure that provides ductility and toughness before heat treatment, laying a solid foundation for subsequent austempering. |

| Austempering Heat Treatment | Critical Microstructure Transformation, with precise control of heating rate, holding temperature and time. | Ausferrite (Bainite + High-Carbon Austenite) with uniform structure. | Achieves ADI's Unique Properties. Precise control of time and temperature (e.g., dipping in salt bath) yields high strength and toughness simultaneously, which is the core process to ensure ADI performance. |

| Precision CNC Machining | Final Dimensional Accuracy and Surface Finish, complying with ISO 8062 tolerance standards. | All Grades of ADI with precise dimensions. | Machining is often required after casting, although Austempering slightly increases hardness, requiring specialized tools. Simis adopts professional cutting tools and processes to ensure machining accuracy and efficiency. |

Shot Peening/Surface Treatment | Fatigue Life Enhancement (Post-treatment), with controlled shot peening intensity and coverage. | Surface Compression Layer with stable performance. | Creates a compressive surface layer, further improving bending fatigue resistance in high-stress areas like gear tooth roots, which has been verified by fatigue test data. |

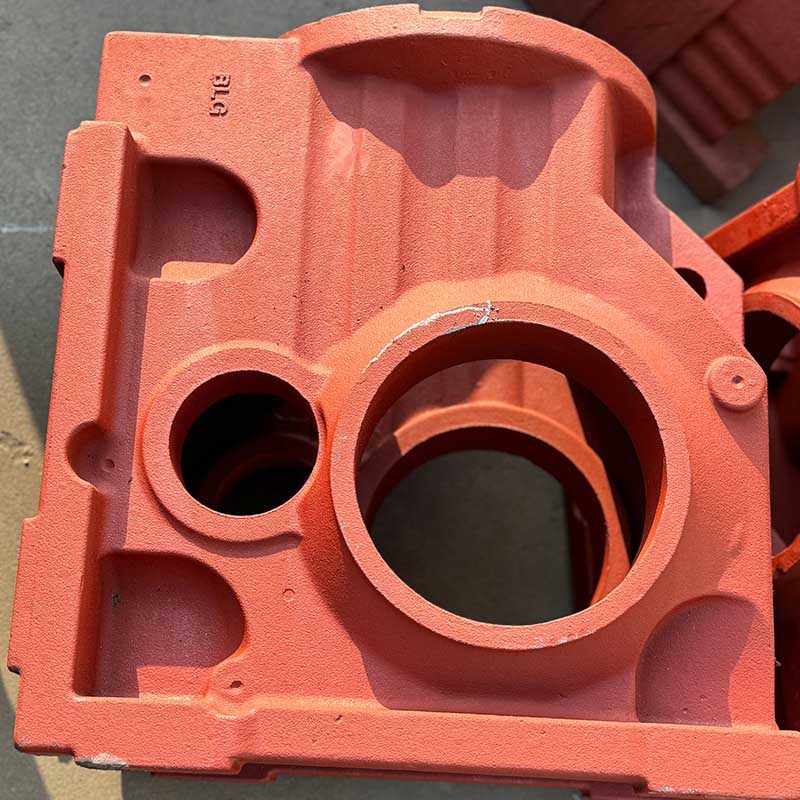

2. What Are the ADI Casting Processes and Their Capabilities?

Simis ability to select the optimal casting process ensures the best surface quality, dimensional precision, and material structure for subsequent heat treatment. Simis's engineering team will customize the most suitable casting process according to the specific requirements of customers' parts.

| Manufacturing Process | Material Focus | Key Advantage for ADI Parts | Specific Process Detail |

| Sand Casting (Resin Sand) | Ductile Iron Precursor with stable chemical composition. | Optimal for Large/Heavy Components. Provides the structural foundation with uniform nodular graphite for subsequent heat treatment, and has high production efficiency for large parts. | Uses high-quality resin sand, adopts computer simulation to optimize the gating system, ensures robust internal soundness (low porosity) critical for ADI performance, particularly in high-stress components. |

| Shell Mold Casting | Ductile Iron Precursor with fine grain structure. | Superior Surface Finish and Closer Tolerance. Used for complex parts where minimal machining is desired post-heat treatment, such as differential components, reducing subsequent processing costs | The shell mold is made of phenolic resin coated sand, with high mold strength and good surface smoothness, improves dimensional accuracy on the casting, minimizing the amount of material that needs to be removed in the hardened state. |

| Lost Foam Casting | Ductile Iron Precursor with complex shape adaptability | High Geometric Complexity (Near Net Shape). Ideal for intricate housings or single-piece components, eliminating complex coring, and improving material utilization | Adopts pre-foamed polystyrene patterns, which can be accurately formed according to complex shapes, reduces weight and fabrication complexity, allowing the part to enter the Austempering process with optimal geometry. |

3. What Are the ADI Material Grades and Their Corresponding Properties?

ADI is classified into several grades based on the achieved mechanical properties, which are controlled by the temperature and time of the Austempering process. Simis strictly follows ASTM A897 standards to produce various grades of ADI materials to meet different application requirements.

| ADI Grade (ASTM A897) | Primary Performance Focus | Typical Application Requirement |

| Grade 80/55/10 (Lower Strength) | Maximum Toughness and Ductility, tensile strength ≥80 ksi, yield strength ≥55 ksi, elongation ≥10% | Components requiring high impact resistance and deformation before failure (e.g., suspension parts), suitable for working environments with frequent impact loads. |

| Grade 120/80/07 (Mid-Range) | High Strength and Excellent Fatigue Life, tensile strength ≥120 ksi, yield strength ≥80 ksi, elongation ≥7% | Ideal for high-load power train gears, couplings, and differential cases, which need to bear continuous high loads and cyclic stresses. |

| Grade 230/185/02 (Highest Strength) | Maximum Hardness and Wear Resistance, tensile strength ≥230 ksi, yield strength ≥185 ksi, elongation ≥2% | Used in severe wear applications like heavy-duty rollers, grinding rings, and track shoes, suitable for harsh working environments with strong abrasion. |

| Ausferrite Matrix | Superior Wear Resistance and comprehensive mechanical properties | The combined structure work-hardens under stress, increasing wear resistance without compromising core toughness, which is the fundamental reason for ADI's excellent performance. |

4. How to Ensure the Quality of ADI Castings in Terms of Microstructure and Integrity?

Quality control for ADI components is heavily focused on verifying the success of the heat treatment process and the resulting microstructure. Simis has established a strict quality assurance system, covering the entire production process from raw material inspection to finished product delivery.

·Microstructure Analysis:

Mandatory verification of the Ausferrite microstructure (bainite and retained austenite) using metallographic inspection to confirm the specified grade and prevent the formation of undesirable brittle phases. Simis uses professional metallographic analysis equipment and has experienced metallurgists to conduct inspections.

·Mechanical Testing:

Verification of Tensile Strength, Yield Strength, and Elongation on samples from each heat treat batch to confirm the material meets the ASTM or ISO grade requirements. All test samples are randomly selected in accordance with relevant standards to ensure the representativeness of the test results.

·Impact Testing (Charpy/Izod):

Used for critical parts (especially Grade 800) to confirm impact toughness and resistance to brittle fracture. The test is carried out at room temperature and low temperature according to the application environment of the parts to ensure the reliability of the parts under different working conditions.

·Non-Destructive Testing (NDT):

Magnetic Particle Inspection (MPI) and Ultrasonic Testing (UT) on the initial ductile iron casting to ensure freedom from internal porosity or solidification defects. Simis's NDT operators are certified by relevant authorities, ensuring the accuracy of inspection results.

5. What Are the Application Areas of ADI Castings for High-Stress and High-Wear Components?

ADI components are widely adopted to replace steel forgings, cast steel, and conventional cast iron parts in sectors requiring durability and weight reduction. With its excellent comprehensive performance, ADI has been successfully applied in many key industrial fields, and has been recognized by customers worldwide.

| Application Sector | Typical ADI Component | Core Performance Needs | ADI Grade Focus |

| Automotive & Truck (Drivetrain) | Differential Cases, Ring and Pinion Gears, Transmission Synchros, Suspension Components. | High Fatigue Strength, High Wear Resistance, Weight Reduction, which helps improve fuel efficiency and vehicle reliability. | Grade 800 - 1000 (Toughness/Strength) |

| Mining & Crushing Equipment | Rollers, Mill Liners, Crusher Hammers, Grinding Rings. | High Hardness for Abrasion, Structural Integrity under Impact, adapting to the harsh working environment of mining. | Grade 1200 (Maximum Wear Resistance) |

| Rail & Mass Transit | Bogie Frames, Rail Track Clips, Braking System Brackets, Wheel Hubs. | High Impact Toughness, Fatigue Resistance, NVH Reduction, ensuring the safety and comfort of rail transit. | Grade 800 - 1000 (Maximum Toughness) |

| General Industrial & Machinery | Crankshafts, Connectors, Hydraulic Manifolds, Sprockets, Couplings. | Structural Integrity, High Strength-to-Weight Ratio, Cost-Efficiency over Forging, reducing equipment manufacturing costs. | Grade 1000 - 1200 (Maximum Strength) |

| Agricultural & Earthmoving | Plowshares, Tillage Tines, Track Shoes, Excavator Teeth, Bushings. | Extreme Abrasion and Impact Wear Resistance, adapting to the complex and harsh working conditions of agriculture and earthmoving. | Grade 800 (High Impact Toughness) |

6. What Is the Metallurgical Advantage of Austempered Ductile Iron (ADI)?

ADI is not simply a cast material; it is a metallurgically enhanced component. The patented austempering process transforms the metal's matrix into Ausferrite—a unique structure composed of bainitic ferrite and stabilized high-carbon austenite. This metallurgical structure is the fundamental reason why ADI has excellent comprehensive performance that is difficult to match with other materials.

This specific microstructure provides ADI components with a combination of benefits unmatched by standard cast iron:

·Exceptional Strength:

Achieving tensile strengths comparable to many alloy steels, and the strength stability is high, which can ensure the consistency of component performance.

·High Wear Resistance:

Superior hardness makes ADI ideal for frictional and abrasive environments, and the wear resistance is verified by long-term industrial application tests.

·Impact Toughness:

Maintains structural integrity even under high dynamic and shock loading, which is significantly better than conventional cast iron materials.

·Cost-Effective Substitution:

ADI often provides the required mechanical properties while offering a significant cost advantage over expensive forgings. It can reduce the manufacturing cost of components by 20%-50% under the premise of ensuring performance.

7. How Does ADI Perform in Comparison with Alternative Materials?

ADI serves as an optimal material solution, allowing engineers to achieve desired performance while optimizing manufacturing costs. The following comparison is based on a large number of experimental data and practical application cases, which can provide a reliable reference for material selection.

| Material | Key Advantage | Typical Applications |

| ADI (Austempered Ductile Iron) | High strength + High toughness + Excellent wear resistance (All in one casting). | Gears, Axles, Suspension Components, Brake Calipers. |

| Standard Ductile Iron | Good castability, vibration damping, lower cost. | Static housings, low-stress applications. |

| Forged Steel | Highest possible fatigue strength, zero porosity. | High-RPM crankshafts, critical flight components. |

| Cast Steel | Good weldability, general toughness. | Large frames, structures not requiring fine precision. |

8. What Are the Advantages of Simis's OEM Customized ADI Casting Services?

Choosing Simis as your ADI OEM partner ensures that you get components engineered specifically for the unique stress requirements of your application. With years of OEM customization experience, Simis integrates professional R&D, strict production control, and comprehensive quality inspection to provide customers with high-value ADI solutions, which is fully reflected in our professional advantages in the field of ADI manufacturing.

·Forging Substitution:

We specialize in transitioning parts traditionally made from costly forgings to optimized, high-performance ADI castings, leading to significant cost reduction without compromising performance.

·Performance Tuning:

The austempering protocol is customized (temperature/time) to achieve the exact ADI grade (e.g., maximizing wear resistance vs. toughness) required by the client.

·Integrated Quality Control:

We manage casting, heat treatment, and final machining in an integrated system, ensuring zero tolerance for structural defects and maintaining precise dimensional compliance.

·Design Optimization:

Our engineering team provides DFM (Design for Manufacturing) support to maximize the inherent benefits of the ADI process.

9. What OEM Custom ADI Casting Services Does Simis Provide?

China Simis Company is an expert partner specializing in high-strength, wear-resistant Austempered Ductile Iron (ADI) parts manufacturing and Iron Casting Services. With professional R&D capabilities, advanced production equipment, and a strict quality management system, we deliver customized ADI solutions to global customers, enhancing the durability and operational efficiency of their equipment. Our professional qualifications and rich project experience ensure that we can meet the diverse needs of customers in different industries.

To get a free professional consultation and detailed quotation, please submit your 2D technical drawings, 3D models, and performance specifications to our engineering department. Simis's professional engineering team will conduct in-depth analysis based on your needs and help you unlock the full potential of ADI in critical applications. We are committed to establishing long-term cooperative relationships with customers based on trust and professional services.