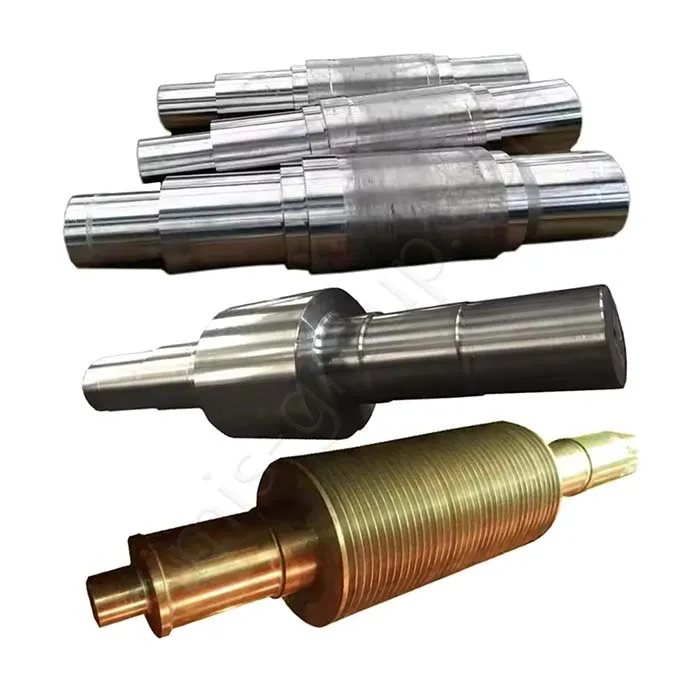

Custom Rolling Mill Roller Shaft Manufacturer

Rolling Mill Roller Shaft

China Simis Company is a specialized OEM custom manufacturer of High-Load Roller Shafts for rolling mills, heavy industrial conveyors, and mining machinery. These shafts are safety-critical components subjected to immense torsional stress, high cyclical bending fatigue, and extreme abrasion and surface wear.

Our manufacturing approach combines Open Die Forging (for large sizes and maximum core strength) and Specialized Casting (for complex, large rollers and composite materials). The key challenge is achieving a composite structure—an ultra-hard, wear-resistant shell with a tough, shock-absorbing core—verified through rigorous heat treatment and NDT protocols.

What are the different classifications of rollers?

| Roller Shaft Type | Primary Stress Profile | Material Focus | Process Focus |

| Rolling Mill Work Rolls | High Surface Stress, Bending Fatigue, Thermal Cycling. | Forged Alloy Steel (or Composite Cast). | Forging, Specialized Heat Treatment/Grinding. |

| Heavy Conveyor Rolls | High Static Bending Load, Surface Abrasion, Torsional Load. | Cast Ductile Iron or Forged Carbon Steel. | Casting (Size/Cost) or Open Die Forging (Max Load). |

| High-Precision Drive Shafts | Extreme Torsional Fatigue, High Rotational Speed. | Open Die Forged Alloy Steel (4340). | Open Die Forging, CNC Machining, Dynamic Balancing. |

What Are the Manufacturing Processes for Roller Shaft?

The process must deliver controlled metallurgical properties across the cross-section, ensuring both long wear life and structural integrity under dynamic load. We adopt 5 core processes including Open Die Forging, Specialized Casting, Induction Hardening/Heat Treatment, Precision CNC Machining & Grinding and Cladding/Overlay Welding to meet different high-load roller shaft production needs.

| Manufacturing Process | Component Focus | Material Focus | Key Advantage for Roller Shaft Performance |

| Open Die Forging | Large Diameter Shafts, Long Barrels, High-Stress Journals. | Alloy Steel (4140, 4340), Carbon Steel. | Maximum Core Integrity and Axial Fatigue Life. The process works the material deeply, aligning the grain structure and eliminating internal porosity in large components. |

| Specialized Casting (Static/Centrifugal) | Large Rolls (Backup Rolls), Ductile Iron Conveyor Rolls, Composite Rolls. | Ductile Iron, Cast Steel, High Chromium Cast Iron. | Metallurgical Versatility. Allows for the creation of composite structures (e.g., hard outer shell on a tough cast core) and is cost-effective for large diameters. |

| Induction Hardening / Heat Treatment | Roll Surface and Shaft Journals. | Alloy Steel, Carbon Steel. | Essential for Wear Profile. Creates a high, controlled surface hardness (HRC 55-65) for wear resistance while maintaining a ductile core to absorb impact. |

| Precision CNC Machining & Grinding | Bearing Seats, Drive Keys, Roll Body Geometry. | All Materials. | Critical for Dynamic Balance and Bearing Life. Ensures ultra-tight tolerances on all interfaces, minimizing runout, vibration, and energy loss during high-speed rotation. |

| Cladding / Overlay Welding | Repair or Surface Enhancement. | High-Chrome or Carbide Alloys. | Application of specialized wear layers to enhance surface hardness and extend roll repair life. |

How to Select Roller Shaft Materials?

Material selection is defined by the need to balance extreme surface hardness for wear against the core toughness required to resist breaking under shock loads. We provide 4 main material types including Alloy Steel, Ductile Iron, High Chromium Cast Iron and Stainless Steel for high-load roller shaft production, each with specific performance advantages matching different application requirements.

| Material Type | Primary Performance Requirement | Typical Roller Shaft Component & Service |

| Alloy Steel (AISI 4140, 4340, D2) | Maximum Torsional Strength, High Hardenability. | Forged Work Rolls and Drive Shafts in demanding industrial production lines and precision rolling mills. |

| Ductile Iron (A536/ADI) | Good Toughness, Cost-Effective, Excellent Castability for Large Parts. | Cast Conveyor Rolls and certain types of Backup Rolls in mining and heavy conveying systems. |

| High Chromium Cast Iron | Extreme Surface Abrasion Resistance. | Cast Sleeves or outer shells of Composite Rolls for grinding/milling applications. |

| Stainless Steel (304, 316) | Corrosion Resistance, Cleanliness. | Conveyor Rolls in food processing, chemical, or pharmaceutical industrial lines. |

What Measures Ensure Roller Shaft Quality Assurance for Structural Integrity and Dynamic Balance?

QA is focused on guaranteeing the complex internal metallurgical structure and the shaft's stability during high-speed, high-load operation. Our core quality assurance measures include Metallurgical Inspection, Non-Destructive Testing (NDT), Dynamic Balancing and Dimensional Precision Control to guarantee each high-load roller shaft meets strict industry standards.

·Metallurgical Inspection:

Microstructure Analysis and Hardness Profile Mapping (surface to core) are mandatory to verify the success of the heat treatment and the desired composite structure.

·Non-Destructive Testing (NDT):

Ultrasonic Testing (UT) is performed on the shaft core/roll body to detect internal flaws and porosity. MPI (Magnetic Particle Inspection) checks the surface for cracks post-grinding.

·Dynamic Balancing:

Mandatory testing for all high-speed roller shafts and rolls to eliminate vibration, reduce bearing wear, and prevent rotational instability under load.

·Dimensional Precision:

CMM verification ensures ultra-tight tolerances on bearing seats, journal surfaces, and keyways for secure and accurate assembly.

What Are the Key Application Areas for Roller Shafts?

Our custom-manufactured roller shafts are integral components in heavy machinery and material processing lines, where component failure results in severe operational loss.

| Application Sector | Key Component Focus | Primary Functional Demand | Material/Process Highlight |

| Metal Processing & Rolling Mills | Work Rolls, Backup Rolls, Mandrels, Spindles. | Extreme Pressure, High Thermal Cycling, Precise Surface Profile. | Forged Alloy Steel (Vacuum Degassed) with specialized surface hardening and deep UT inspection. |

| Heavy Material Conveying | Idler Rolls, Drive Shafts for Belt Conveyors (Mining, Quarry). | High Static Bending Load, Constant Abrasion, Shock Load Tolerance. | Cast Ductile Iron or LFC Cast Steel (Cost/Size optimized), focused on bearing fit and static integrity. |

| Printing & Paper Industry | Tension Rolls, Press Rolls, Transfer Shafts. | High Rotational Speed, Ultra-low Runout (Vibration), Surface Finish. | Forged Carbon Steel with dynamic balancing and ultra-precision grinding for uniform material transfer. |

| Agricultural & Construction Machinery | Power Transmission Shafts, Ground-Contact Tines/Rolls. | High Torsional Shock Load, Dirt/Contaminant Resistance, Toughness. | Forged Alloy Steel (4140) or robust Cast Steel, emphasizing resistance to brittle fracture. |

What Are the Advantages of Simis OEM Custom Roller Shafts?

Simis delivers high-performance roller shafts engineered for maximum throughput, minimized downtime, and certified longevity in extreme environments.

·Open Die Forging Expertise:

We utilize Open Die Forging for critical shafts, guaranteeing maximum internal soundness, grain flow optimization, and the highest possible resistance to fatigue and fracture in large components.

·Metallurgical Expertise:

We excel at controlling the composite structure (hard case, tough core) through advanced heat treatment and specialized casting techniques, optimizing the roll for its specific application.

·Guaranteed Torsional Strength:

Our focus on forging ensures maximum yield strength and resistance to torsional fatigue failure.

·Precision Finishing:

We achieve the ultra-low Ra values and dynamic balance required for smooth, high-speed operation, extending bearing life and reducing system vibration.

How to Get a Quote for Custom Roller Shafts?

China Simis Company is your expert global partner for custom cast and forged Roller Shafts, engineered for extreme wear resistance, superior torsional fatigue strength, and certified precision.

Please submit your 2D technical drawings, CAD models, required material grade (e.g., 4140 or Ductile Iron), specified surface hardness profile (e.g., HRC 60 case depth), NDT requirements (UT coverage), and dynamic balance specifications to our engineering department for a consultation and detailed quotation.