Forged aluminum improves e-bike performance

With the rapid development of electric bicycles, lightweight, high strength, and durability are key requirements. Forged aluminum is an aluminum alloy material strengthened through plastic deformation. Its core advantage lies in the significant improvement of the metal's microstructure through machining, resulting in mechanical properties superior to those of cast aluminum. Due to its excellent performance, forged aluminum has gradually become the "skeleton" and "joint" of mid- to high-end electric bicycles.

1. Core advantages of forged aluminum

(1) Material performance advantages

Forged aluminum changes the microstructure of aluminum alloy through plastic deformation, showing significantly better properties than cast aluminum:

Strength improvement:

The tensile strength of 6061-T6 forged aluminum reaches 310MPa, which is 42% higher than that of the cast state

Fatigue life:

In a 2 million cycle load test, the crack initiation time of forged aluminum is extended by 8 times

Lightweight:

The density is only 2.7g/cm³, which is 65% lighter than steel

Thermal conductivity:

167W/m·K, which is better than the 96W/m·K of cast aluminum

(2) Microstructure improvement

·Grain size is refined from 100-200μm in the cast state to 10-20μm

·Dislocation density is increased from 10¹²/m² to 10¹⁴-10¹⁵/m²

·The distribution of strengthening phase is more uniform

(3) Economic Analysis

Although the initial cost of forgings is high, comprehensive considerations include:

·Service life is extended by 3-5 times

·Maintenance costs are reduced

·Energy efficiency is improved

·Total cost of ownership (TCO) is more advantageous

2. Key applications in electric bicycles

(1) Drivetrain

Crankset:

7075-T73 forged aluminum, reducing weight by 40% while increasing rigidity

Sprocket:

Cold forging process ensures tooth profile accuracy and extends chain life

Mid-axis:

One-piece forging to eliminate welding weaknesses

(2) Frame components

Bottom bracket shell:

6082-T6 forged aluminum, with precisely controlled wall thickness

Head tube connection:

Multi-directional die forging ensures isotropy

Rear fork pivot:

Local reinforcement treatment

(3) Travel system

Wheel hub:

Forged aluminum hub increases lateral rigidity by 28%

Brake caliper:

Forged aluminum has excellent heat dissipation performance

Pedal shaft:

Bending strength increased by 50%

(4) Electrical System

Motor Housing:

Optimized Heat Dissipation Channel Design

Battery Bracket:

Balances Vibration Reduction and Lightweighting

3. Key Manufacturing Processes

(1) Forging Process Selection

| Process Type | Temperature Range | Precision Control | Applicable Scenarios |

| Cold Forging | Room Temperature | ±0.1mm | Small Precision Parts |

| Warm Forging | 200-300℃ | ±0.2mm | Complex Shape Parts |

| Isothermal Forging | 400-450℃ | ±0.3mm | Large Structural Parts |

(2) Typical Process Flow

Taking 6061-T6 wheel hub as an example:

Blank Preparation:

DC Casting → Homogenization (560°C x 8 hours)

Pre-forging:

Initial forging using a 2500-ton hydraulic press

Fine Forging:

Closed Die Forging with a controlled deformation of 30-40%

Heat Treatment:

Solution Treatment (530°C x 2 hours) → Water Quenching → Aging (175°C x 8 hours)

Finishing:

CNC Milling (IT7-grade precision)

4. Common defects and control

(1) Defect types and causes

| Defect | Generation mechanism | Detection method |

| Folding crack | Uncoordinated metal flow | Penetrant testing |

| Coarse grain ring | Excessive surface shear deformation | Metallographic analysis |

| Oxide inclusions | Heating process contamination | X-ray inspection |

(2) Control measures

· Material control:

Raw material purity ≥ 99.7%

Sufficient homogenization treatment

· Process optimization:

Mold temperature control ± 5°C

Deformation rate optimization

· Equipment guarantee:

Nitrogen protective atmosphere

Precision temperature control system

(3) Quality inspection standards

Dimension tolerance: ± 0.1 mm

Surface roughness: Ra ≤ 1.6 μm

Mechanical properties: Comply with ASTM B247

Non-destructive testing: UT/RT full coverage

5. Industry Application Cases

(1) High-end Vehicle Applications

Specialized: Forged aluminum crankset reduces weight by 300g

Trek: One-piece forged bottom bracket increases rigidity by 15%

Giant: Forged aluminum wheel hub increases endurance by 5%

(2) Mass-produced Vehicle Breakthroughs

Yadea: Mass-produced motor housing costs reduced by 20%

(3) Special Vehicle Adaptation

Freight Vehicle: Load-carrying capacity increased by 50%

Mountain Bike Vehicle: Impact toughness requirements met

6. Technical and Economic Analysis

(1) Cost Structure

Material Material cost: 40-45%

Manufacturing cost: 30-35%

Heat treatment cost: 15-20%

Testing cost: 5-10%

(2) Value return

Extended service life → Reduced replacement frequency

Improved performance → Product premium

Lightweight → Improved energy efficiency

(3) Return on investment

High-end models: 1-2 years

Mass models: 2-3 years

Forged aluminum technology has brought revolutionary performance improvements to electric bicycles, reflecting the essence of modern manufacturing from material science to manufacturing processes. With the continuous advancement of process technology and the emergence of scale effects, forged aluminum will play a more important role in the field of electric bicycles, driving the entire industry towards a more efficient and reliable direction.

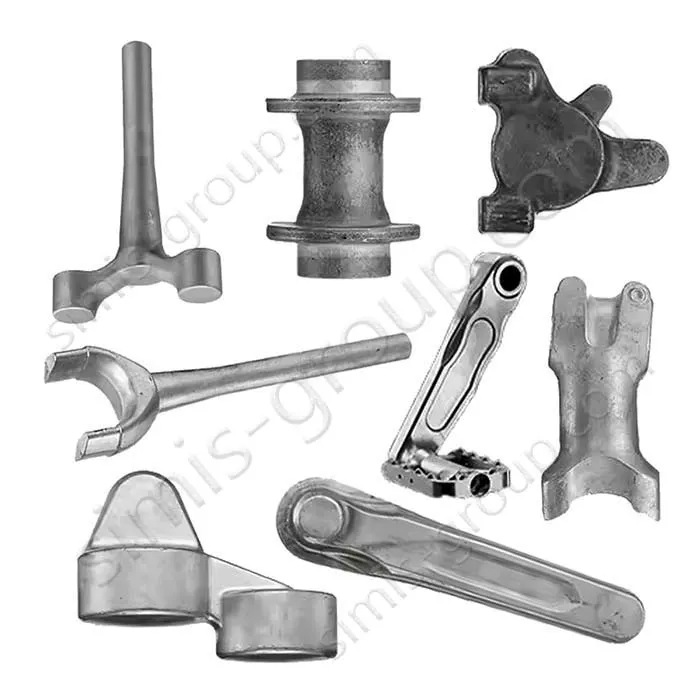

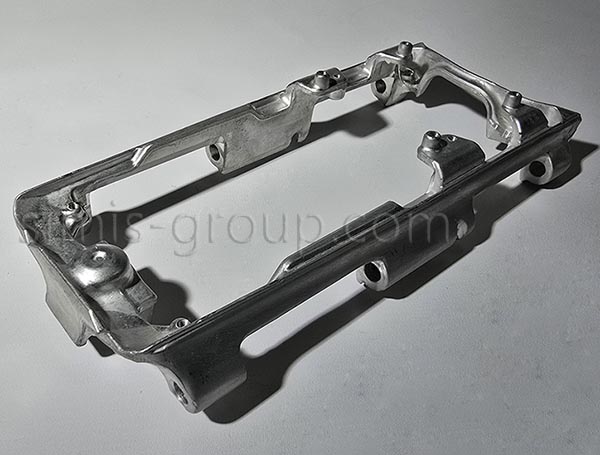

7. Conclusion: SIMIS Group - Your partner for forged aluminum technology

In today's rapidly developing electric bicycle industry, the application of high-performance forged aluminum components has become the key to improving product competitiveness. As a professional metal forging manufacturer, SIMIS Group is committed to providing customized forged aluminum parts solutions to global electric vehicle manufacturers and suppliers, encompassing a comprehensive service process from material selection and process optimization to quality inspection.

Our core services include:

Material Research:

Based on your product requirements, we recommend the optimal aluminum alloy grade (such as 6061-T6, 7075-T73, 6082-T6, etc.), balancing strength, weight, and cost.

Process Consultation:

We offer various process options, including cold forging, warm forging, and isothermal forging, to ensure optimal product precision, performance, and mass production feasibility.

Quality Control:

We strictly adhere to ASTM/ISO/EN standards and utilize advanced testing methods such as ultrasonic testing (UT), X-ray testing (RT), and coordinate measurement (CMM) to ensure zero defects.

OEM/ODM Support:

From design optimization to mass production, we provide one-stop customized forged aluminum parts services to meet the individual needs of diverse customers.

Whether it's the middle axle, crank, or hub for high-performance e-bikes or reinforced structural parts for special vehicles, SIMIS Group can help your products stand out in the market with leading forging technology, rigorous quality control, and efficient supply chain management.