How to Choose an OEM Valve Parts Manufacturer | Buyer Guide

Valves and valve parts are the control core of pipeline systems, directly affecting safety, efficiency, and long-term operating costs in industries such as oil & gas, petrochemical, power generation, water treatment, and municipal infrastructure.

For buyers, choosing a reliable OEM custom valve and valve parts manufacturer is far more than a routine purchasing task. OEM cooperation involves complex challenges including design customization, mold development, precision manufacturing, quality consistency, certification compliance, and intellectual property protection. A wrong decision can lead to costly delays, quality failures, or compliance risks.

Based on extensive experience in cross-border OEM sourcing, this guide provides a systematic and practical framework to help buyers identify, evaluate, and cooperate with professional OEM valve manufacturers with confidence.

Step 1: Clearly Define Your OEM Custom Valve Requirements

Before contacting any OEM valve manufacturer, clearly defining your customization needs is essential. Vague or incomplete requirements often result in inefficient communication, repeated revisions, and products that fail to meet real operating conditions.

1. Working Conditions & Performance Requirements

For both custom valves and valve parts (such as valve bodies, stems, discs, handwheel and seats), clarify the following:

·Medium: water, oil, gas, steam, corrosive chemicals, etc.

·Operating temperature: low, medium, or high temperature

·Operating pressure: PN10/16/40/64 or Class 150–2500

·Special requirements: corrosion resistance, wear resistance, high precision, long service life

For example, valve seats used in petrochemical applications require excellent corrosion and high-temperature resistance, while precision valve stems demand extremely tight dimensional tolerances.

2. OEM Custom Specifications

Clearly define all technical specifications, including:

·Product type (gate valve, ball valve, globe valve, check valve, or specific valve parts)

·Material (cast iron, carbon steel, stainless steel, duplex steel, aluminum alloy, copper alloy, cspecial alloys)

·Dimensions and tolerances (technical drawings or 3D models are highly recommended)

·Connection type and surface treatment

·Manufacturing process requirements

Typical processes include:

·Sand casting / shell mold casting for valve bodies, stems, discs (tolerance ±0.5 mm)

·Investment casting for precision valve parts (tolerance ±0.05 mm)

·Open-die or closed-die forging for high-pressure valve stems (forging ratio ≥ 4:1)

Also confirm applicable standards for your target market, such as API, ASME, EN, DIN, or ISO, and clarify any OEM branding requirements.

3. OEM Procurement Details

Key commercial factors to confirm early include:

·Order quantity and batch size

·Mold development cost and lead time (if new molds are required)

·Sample approval process

·Mass production delivery schedule

·Budget range

OEM valve and valve parts manufacturing places high demands on a supplier’s R&D and mold development capabilities. A clear budget and timeline help filter suitable OEM partners efficiently.

Step 2: Where to Find Reliable OEM Custom Valve Manufacturers

A combination of online and offline channels provides the most comprehensive supplier screening.

Online Channels

Professional B2B platforms such as Kompass, Thomasnet, and Europages allow you to search for manufacturers using keywords like “OEM custom valve manufacturer” or “OEM valve parts supplier.”

Trade data platforms such as Panjiva can reveal export records, shipment volumes, and long-term OEM cooperation history—valuable indicators of international experience and production stability.

Focus on manufacturers that clearly describe their OEM process, customization capabilities, certifications, and export experience. Avoid suppliers with vague descriptions or limited technical documentation.

Offline Channels

International exhibitions such as Valve World Expo, ADIPEC, and Hannover Messe are excellent venues to meet OEM valve manufacturers face to face. These events allow you to:

·Communicate directly with technical teams

·Inspect OEM samples

·Discuss customization feasibility in detail

In addition, recommendations from industry associations, experienced peers, or local trade promotion agencies often lead to more reliable OEM partners.

Step 3: Verify Certifications and Compliance

Certifications are the foundation of trust in OEM valve manufacturing, especially for cross-border projects.

Essential Certifications

·ISO 9001 – Quality management system (mandatory)

·ISO 14001 / ISO 45001 – Environmental and occupational safety management

Product & Market-Specific Certifications

·CE certification for European markets

·API and ASME certifications for North America

·CSA certification for Canada

For OEM valve parts, ensure the manufacturer has proven experience meeting precision manufacturing and consistency requirements.

Certification Verification

Always verify certificate authenticity through the issuing authority’s official website or request original documents and audit reports. This step is critical, as false certifications still exist in the market.

Step 4: Evaluate OEM Technical and Manufacturing Capabilities

Certifications open the door, but real OEM customization capability determines long-term success.

OEM R&D and Mold Development

--Ask about:

·Size and experience of the R&D team

·Ability to optimize customer designs

·Mold development lead time and precision

--For example:

·Sand casting pattern development: 15–25 days

·Investment casting dies: 20–30 days

·CNC mold machining accuracy: ±0.02 mm

Request real OEM case studies, technical drawings, and performance data to verify experience.

Production Equipment and Process Control

Reliable OEM valve manufacturers should have advanced equipment, including:

·Casting lines and wax injection machines

·Forging presses and hammers

·5-axis CNC machining centers

·Precision grinding and finishing equipment

Quality control should include:

·CMM dimensional inspection (±0.005 mm)

·X-ray testing for cast valve bodies

·Ultrasonic testing for forged valve stems

A complete OEM production workflow—from design review to mass production—ensures consistent quality.

Production Capacity and Supply Chain Stability

Evaluate:

·Annual OEM production capacity

·Sample lead time (7–20 days depending on process)

·Mass production lead time (typically 25–50 days)

·Ability to handle sudden volume increases

Manufacturers with in-house casting and forging workshops and stable raw material suppliers are generally more reliable OEM partners.

Step 5: OEM Quality Control and After-Sales Support

Long-term OEM success depends on strict quality control and responsive after-sales service.

OEM-Specific Quality Control

Ensure the manufacturer conducts:

·Raw material composition analysis

·Dimensional and performance testing

·Pressure testing (up to 1.5× rated pressure for valves)

For critical parts, request full inspection reports and consider third-party inspections.

After-Sales Service

Confirm:

·Technical support for design adjustments

·Spare parts lead time (ideally ≤ 7 days)

·Response time for quality issues (≤ 48 hours)

·Warranty terms and compensation mechanisms

Step 6: Review OEM Cooperation Cases and Reputation

Ask for OEM projects similar to your own, especially in the same industry or market. Reliable manufacturers typically demonstrate:

·Stable long-term international clients

·High repurchase rates (often above 90%)

·Positive feedback on quality consistency and delivery performance

Reviews from B2B platforms and direct client references further strengthen credibility.

Step 7: Key Considerations for Cross-Border OEM Cooperation

When negotiating contracts, pay close attention to:

·Total cost structure (including molds, samples, and testing)

·Logistics responsibilities and customs documentation

·Intellectual property protection and mold ownership

·Payment terms and risk-sharing mechanisms

Clear contractual terms significantly reduce OEM cooperation risks.

Building a Reliable OEM Valve Manufacturing Partnership

Choosing a reliable OEM custom valve and valve parts manufacturer requires a structured approach—clear requirements, thorough supplier screening, strict capability evaluation, and careful attention to cooperation details.

By following this framework, buyers can significantly reduce procurement risks and build long-term, mutually beneficial OEM partnerships. A truly professional OEM manufacturer delivers not only qualified products, but also technical support, stability, and strategic value.

About China Simis Company

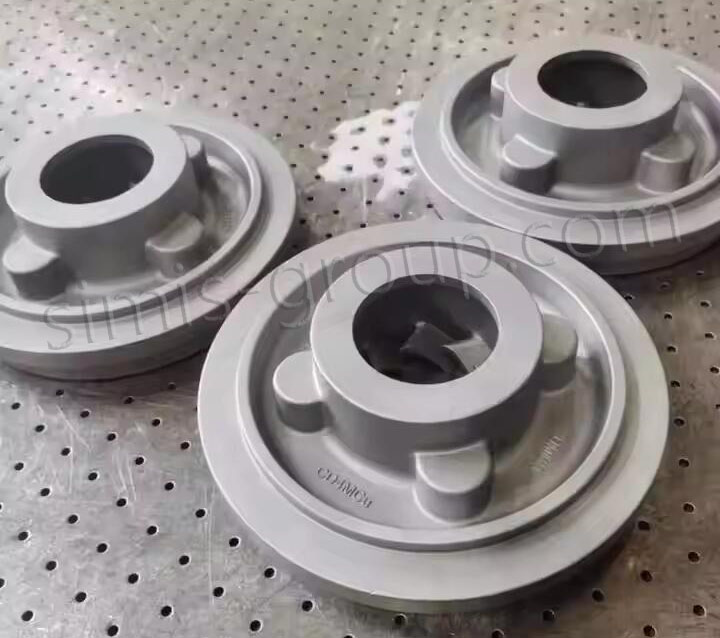

China Simis Company is a professional OEM custom valve and valve parts manufacturer, specializing in casting and forging solutions for global customers. Based on customer-provided drawings, 3D models, material specifications, and performance requirements, the company delivers fully customized valve and valve parts solutions.

With advanced manufacturing processes—including sand casting, shell mold casting, lost foam casting, investment casting, open-die forging, and closed-die forging—as well as strict quality control systems such as X-ray and ultrasonic NDT, China Simis Company ensures every OEM product meets international technical standards and application demands.

Whether for small-batch precision casting parts or large-scale forged valve bodies, China Simis Company provides reliable quality, stable delivery, and professional OEM support, making it a trusted long-term partner for buyers.