What Is Hot Forging?

Hot forging, as a core metal manufacturing process for high-performance components, plays an irreplaceable role in global critical industrial sectors. This comprehensive technical guide systematically elaborates on hot forging, covering its formal definition, core principles based on metal recrystallization characteristics, material compatibility and corresponding process requirements, standardized process steps, classification by die structure and deformation characteristics, key advantages in critical component manufacturing, quality assurance and process control essentials, common defects and targeted prevention/remedial measures, typical applications across industries such as industrial and automotive, as well as a comparative analysis with warm forging and cold forging.

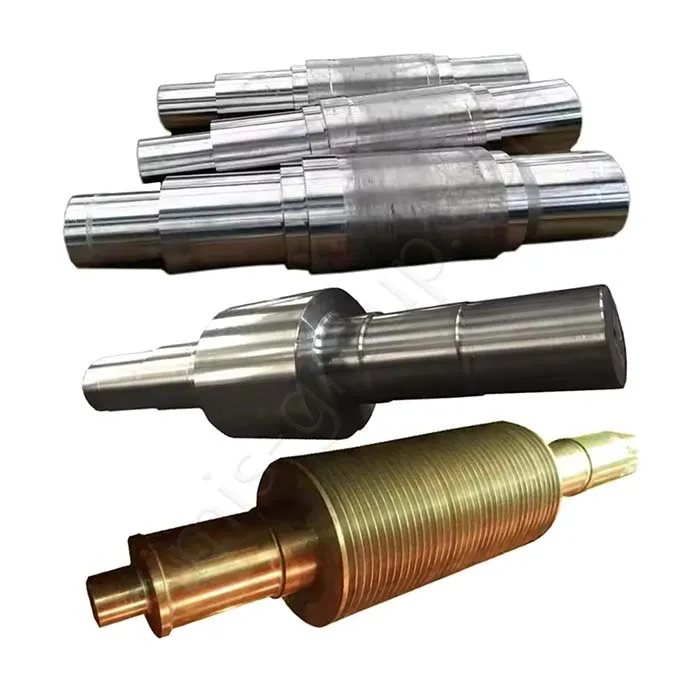

(Open Die Hot Forging)

1. What Is Hot Forging?

In accordance with international forging standards (including the general principles specified in ISO and ASTM standards) and industrial terminologies, hot forging is formally defined as the process of shaping metal workpieces through the application of localized compressive forces at temperatures exceeding the material’s recrystallization temperature. This critical temperature threshold is not fixed but varies depending on the type of metal. For instance, the hot forging temperature for steel typically ranges from 900°C to 1250°C (1652°F to 2282°F), whereas aluminum alloys are subjected to hot forging within the temperature range of 380°C to 500°C (716°F to 932°F).

The core principle of hot forging resides in the utilization of the modified properties of metals at elevated temperatures. When a metal is heated above its recrystallization temperature, the mobility of its atoms increases substantially, thereby reducing the material’s yield strength and significantly enhancing its ductility. This enhanced ductility facilitates the deformation of the metal with reduced applied force, enabling it to flow smoothly into complex geometries within forging dies. Critically, the recrystallization process occurring during hot forging eliminates strain hardening—a phenomenon prevalent in cold forging—and refines the metal’s grain structure, ultimately resulting in components with uniform mechanical properties and enhanced toughness.

(Open Die Hot Forging)

2. How Do Hot Forging, Warm Forging, and Cold Forging Differ?

It is essential to differentiate hot forging from other conventional forging techniques, namely cold forging (conducted at or near ambient temperature, below the recrystallization temperature) and warm forging (performed at intermediate temperatures between cold and hot forging). In contrast to cold forging, which relies on strain hardening to achieve strength, the strength advantage of hot forging is derived from grain refinement and the elimination of internal defects.

To selecting the appropriate forging process, the key characteristics of hot forging, warm forging, and cold forging are compared in the following table:

| Comparison Index | Hot Forging | Warm Forgin | Cold Forging |

| Temperature Range | Above the recrystallization temperature (e.g., steel: 900°C-1250°C; aluminum alloy: 380°C-500°C | Between ambient temperature and recrystallization temperature (e.g., steel: 400°C-800°C) | At or near ambient temperature (≤50°C) |

Formability | Excellent, capable of forming complex geometries and large workpieces | Good, better than cold forging but inferior to hot forging | Limited, suitable for simple or moderately complex shapes |

Mechanical Properties | Superior toughness, uniform grain structure, no residual stress (after proper cooling) | Balanced strength and toughness, moderate grain refinement | High strength and hardness due to strain hardening, but relatively low toughness |

Dimensional Accuracy | Moderate (tolerance: ±0.1mm-±0.5mm), requiring secondary machining for high precision | High (tolerance: ±0.05mm-±0.2mm), lower secondary machining demand | Very high (tolerance: ±0.01mm-±0.1mm), near-net-shape production achievable |

| Surface Quality | General, may have oxidation scale, requiring post-processing | Good, less oxidation than hot forging, smooth surface | Excellent, no oxidation, bright surface |

| Deformation Force | Lowest, reducing equipment wear | Medium, between hot and cold forging | Highest, requiring high-performance forging equipment |

| Material Utilization Rate | Medium to high, flash generation varies by die type | High, less flash than hot forging | Highest, minimal material waste |

| Application Scenarios | Large-scale components, critical high-stress parts (e.g., aircraft landing gear, crankshafts, wind turbine flanges) | Medium and small-sized precision components (e.g., automotive gears, fasteners) | Small precision parts (e.g., bolts, nuts, small gears, electronic components) |

| Production Cost | Medium, considering heating and post-processing costs | Medium to high, balancing precision and process complexity | High initial equipment investment, but low per-unit cost for mass production |

The above comparison table clearly illustrates the differences between the three forging processes. For procurement professionals, the selection should be based on the product's size, complexity, performance requirements, production volume, and cost budget. Hot forging remains the preferred choice for critical components requiring high toughness, complex geometries, or large dimensions, while cold forging is more suitable for small, high-precision parts in mass production. Warm forging serves as a balanced solution for applications requiring both moderate precision and mechanical properties.

(Cold Forging)

3. What Are the Process Steps of Hot Forging?

The hot forging process follows a systematic sequence of steps to ensure product quality and process stability, adhering to international manufacturing standards. The core process steps are as follows:

(1) Raw Material Preparation:

Select high-quality metal billets or ingots that meet the chemical composition and mechanical property requirements of the target product. Common raw materials include carbon steel, alloy steel, and non-ferrous metal alloys. The billets are cut to the specified weight and size to ensure uniform deformation during forging.

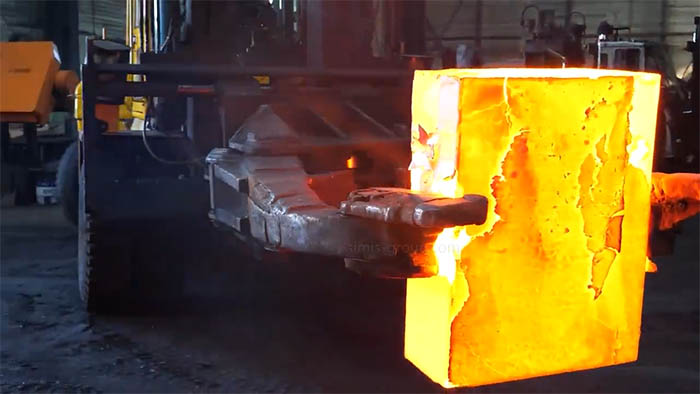

(2) Preheating:

Place the prepared raw materials into heating furnaces for preheating. The heating rate and temperature are strictly controlled to avoid overheating, underheating, or uneven temperature distribution. Preheating aims to reduce the yield strength of the metal and improve its ductility, laying the foundation for subsequent deformation.

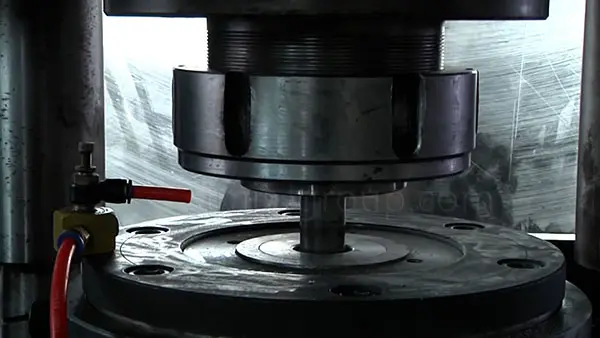

(3) Forging Deformation:

Transfer the preheated billet to forging equipment (such as hydraulic presses, mechanical presses, or hammer forges) and apply localized compressive forces to shape it into the desired geometry using pre-designed dies. The deformation process must be completed within the optimal temperature range to ensure uniform metal flow and avoid cracks.

(4) Trimming and Deburring:

After forging, remove excess material (flash) generated during the deformation process using trimming dies. Simultaneously, eliminate burrs and sharp edges to meet the initial dimensional requirements of the product.

(5) Cooling:

Cool the forged workpiece uniformly according to the material characteristics and product requirements. Common cooling methods include air cooling, furnace cooling, and water cooling. Proper cooling prevents warping, residual stresses, and material property degradation caused by rapid temperature changes.

(6) Post-Processing:

Conduct subsequent processing as needed, including heat treatment (such as quenching, tempering, or annealing) to optimize the mechanical properties of the workpiece; machining to achieve precise dimensional tolerances and surface quality; and surface treatment (such as anti-corrosion coating) to enhance the product's service life in harsh environments.

(7) Quality Inspection:

Implement multi-stage quality testing throughout the process, including chemical composition analysis of raw materials, temperature monitoring during heating, dimensional inspection after forging, and non-destructive testing (such as ultrasonic testing, magnetic particle testing) to detect internal and surface defects. Only products that meet the quality standards are allowed to leave the factory.

(Heating The Billet)

4. What are the different types of hot forging processes?

Based on mold structure and deformation characteristics, hot forging can be divided into open forging, closed forging, extrusion, and ring rolling. Each type has its unique application scenarios and technical advantages. Detailed classifications are shown in the table below:

| Type of Hot Forging | Alternative Name | Core Characteristics | Application Scenarios |

| Open Die Hot Forging | Free Forging | Uses simple dies or no dies; the billet can be freely deformed in multiple directions; low requirement for die design complexity. | Production of large-scale, low-batch workpieces such as large shafts, flanges, and ingot forgings, customization needs of large-scale industrial components. |

| Closed Die Hot Forging | Impression Die Forging | Uses dies with closed cavities matching the target product shape; little or no flash generated during deformation; high dimensional accuracy and surface quality. | Mass production of medium and small-sized precision components such as automotive connecting rods, crankshaft, gears, and aerospace fasteners. |

| Ring Rolling Hot Forging | Ring Forging | Specialized for annular workpieces; the preheated billet is rotated between a driving roll and a mandrel to gradually expand into a ring; uniform grain flow along the annular direction. | Production of annular workpieces such as bearings, flanges, and rings for wind turbines. |

| Extrusion Hot Forging | - | The billet is placed in a closed container; pressure is applied to force the metal to flow out through a die hole of specific shape; high material utilization rate. | Production of non-ferrous metal and alloy components with complex cross-sections such as pipes, profiles, and hollow components. |

(Closed-Die Forging)

5. Which Materials Are Suitable for Hot Forging?

Hot forging is suitable for a variety of metals and alloys, but the forging process parameters and technical requirements vary significantly depending on the material properties, thus affecting the quality of the forgings. Detailed requirements for typical hot forging materials are as follows:

| Material Type | Optimal Hot Forging Temperature Range | Key Forging Characteristics | Common Issues & Mitigation Measures | Typical Applications |

| Carbon Steel | 900°C-1200°C | Good ductility and formability; low deformation resistance; cost-effective | Issue: Easy decarburization during heating. Mitigation: Control heating time and use protective atmosphere; perform post-forging grinding. | Automotive crankshafts, connecting rods, general machinery parts |

| Alloy Steel | 850°C-1250°C (varies by alloy content) | High strength and toughness after forging; good wear resistance; relatively high deformation resistance | Issue: Alloy element segregation affecting uniformity. Mitigation: Adopt uniform heating; control deformation rate; conduct heat treatment after forging. | Aerospace structural parts, high-pressure valve cores, gear shafts |

| Stainless Steel | 1050°C-1200°C | Excellent corrosion resistance; high temperature resistance; relatively poor formability | Issue: Oxidation and chromium depletion. Mitigation: Use vacuum or inert gas heating; optimize cooling rate to avoid intergranular corrosion. | Chemical equipment parts, marine components, high-temperature fasteners |

| Aluminum Alloy | 380°C-500°C | Lightweight; good thermal conductivity; low deformation force; fast cooling rate | Issue: Easy oxidation and grain coarsening. Mitigation: Strictly control heating temperature and time; use protective coating on billet surface. | Aerospace lightweight components, automotive aluminum alloy wheels, heat exchanger parts, bicycle parts, Triple Clamp Yoke |

| Titanium Alloy | 800°C-1050°C | High specific strength; excellent high-temperature performance; poor formability | Issue: Severe oxidation and absorption of oxygen/nitrogen at high temperatures. Mitigation: Use vacuum heating furnace; forge in protective atmosphere; minimize high-temperature exposure time. | Aerospace engine blades, rocket components, medical devices |

(Hot-Forged Aluminum Alloy Parts)

6. Why Is Hot Forging Preferred for Critical Components?

The widespread adoption of hot forging in industrial applications is attributed to its distinct set of advantages, which have been validated through decades of industrial practice and are aligned with global quality standards for high-performance components:

·Enhanced Formability for Complex Geometries:

The high-temperature environment enables metals to be shaped into intricate configurations that would be challenging or unattainable through cold forging. This characteristic is particularly advantageous for custom forgings, such as crankshafts, aircraft turbine blades, and large-scale industrial flanges.

·Superior Mechanical Properties:

Hot forging refines the metal’s grain structure, generating a uniform, dense microstructure with continuous grain flow that conforms to the component’s shape. This process eliminates internal defects such as porosity, shrinkage, and voids, thereby significantly enhancing the component’s strength, toughness, and fatigue resistance—attributes that are critical for parts subjected to high stress, heavy loads, or extreme operating conditions.

·Reduced Deformation Force and Equipment Wear:

The lower yield strength of metals at elevated temperatures reduces the force required for deformation. This not only minimizes wear on forging equipment (including presses and dies) but also enables the processing of larger, thicker workpieces—with weights of up to 170 metric tons.

·Material Versatility:

Hot forging is compatible with a broad spectrum of metals and alloys, including carbon steel, alloy steel, stainless steel, copper, aluminum, nickel, and titanium alloys. This versatility renders it suitable for meeting the diverse requirements of industries spanning automotive, aerospace, and energy sectors.

·Cost-Efficiency in High-Volume and Custom Production:

For the high-volume production of complex components, hot forging minimizes the necessity for secondary machining—particularly in closed-die hot forging—thereby reducing material waste and overall production costs. In the context of custom forgings, it provides flexibility in shaping unique designs without compromising performance, which is a key advantage for specialized industrial applications.

(Closed Die Hot Forging Alloy Steel Oil Valve Parts)

7. What are the key factors to consider in the quality control of hot forgings?

While hot forging offers substantial benefits, the achievement of consistent, high-quality results necessitates strict adherence to process control protocols and international standards. Key considerations include the following:

·Precise Temperature Control:

Maintaining the metal within the optimal hot forging temperature range is critical. Overheating can degrade the metal’s properties (e.g., inducing grain coarsening), while underheating may result in insufficient ductility and increased deformation force. Modern hot forging facilities employ infrared real-time monitoring systems to control temperatures with a tolerance of ±5°C.

·Die Design and Maintenance:

Dies play a crucial role in shaping the forging. High-quality dies—typically fabricated from heat-resistant alloys—must be appropriately preheated (usually to 300°C) to prevent thermal shock and ensure uniform metal flow. Regular maintenance and the application of advanced coatings (e.g., nano-coatings) serve to reduce friction and extend die service life.

·Atmosphere Control:

Heating metals at high temperatures may induce oxidation and scaling, which can adversely affect the forging’s surface quality. To mitigate these issues, certain hot forging processes utilize protective atmospheres (e.g., inert gases) or advanced heating technologies.

·Cooling and Post-Processing:

Subsequent to forging, components must undergo uniform cooling to avoid warping or residual stresses. Depending on the specific application requirements, post-processing steps (e.g., heat treatment, machining, or surface finishing) may be necessary to achieve the final dimensional tolerances and surface quality standards.

8. What are the common defects in hot forgings?

Despite strict process control, hot forging components may still have defects due to factors such as raw material quality, process parameter deviations, and die design issues. Timely identification of common defects and implementation of targeted prevention and remedial measures are critical to ensuring product quality. The details are as follows:

(Cracks Appeared In The Forgings)

| Defect Type | Causes | Prevention Measures | Remedial MeasuresCracks |

| Cracks | 1. Uneven heating or overheating/underheating of billet; | 1. Optimize heating curve to ensure uniform temperature; | 1. Small cracks: Grind and repair, then re-inspect; |

| Folding | 1. Unreasonable die design leading to uneven metal flow; | 1. Optimize die cavity design to guide uniform metal flow; | 1. Minor folding: Grind to remove the folded part; |

| Shrinkage and Voids | 1. Insufficient forging deformation leading to incomplete metal filling; | 1. Ensure sufficient forging ratio to improve metal density; | 1. Small shrinkage/voids: Repair by welding (for non-critical parts) or re-forging; |

| Grain Coarsening | 1. Overheating of billet or prolonged high-temperature exposure; | 1. Strictly control heating temperature and time; | Implement reheat treatment (e.g., normalizing, annealing) to refine grains; if grain coarsening is severe, re-forging may be required. |

| Oxide Scale and Decarburization | 1. Heating in air atmosphere leading to oxidation; | 1. Use protective atmosphere heating or vacuum heating; | Remove oxide scale by shot blasting or grinding; repair decarburized layer by machining (ensure the remaining material meets thickness requirements). |

China Simis Group and its subsidiary Shanxi KSN Precision Forging Technology Development Co., Ltd. have established a comprehensive defect control system. By integrating advanced non-destructive testing equipment (such as 3D laser inspection and ultrasonic testing) and strict process monitoring, the company effectively reduces defect rates and ensures the delivery of high-quality hot forging components to global customers.

9. In which industries can parts produced by hot forging be applied?

The combination of strength, formability, and versatility inherent in hot forging makes it indispensable in industries where component failure is intolerable. Key applications are as follows:

·Aerospace:

Fabrication of critical components such as aircraft landing gear, engine turbine disks, blades, and structural fittings—parts that must withstand extreme temperatures, pressure, and fatigue.

·Automotive:

Manufacturing of high-stress components, including crankshafts, connecting rods, gears, axle spindle shafts, and suspension parts. Hot-forged automotive components ensure reliability and safety under sustained loads and vibration.

·Energy and Oil/Gas:

Production of large-scale components such as wind turbine flanges, slewing bearing ring, oil drill pipes, power plant pressure vessels, and turbine components—all of which require exceptional strength and resistance to harsh operating environments.

·Heavy Machinery and Construction:

Forging of excavator buckets, crane hooks, bulldozer components, and other heavy-duty parts that are required to withstand high impact and static loads.

·Marine:

Manufacturing of ship propellers, shafting, and hull components—engineered to resist corrosion and fatigue in marine environments.

(Closed-Die Forging Automotive Connecting Rod)

10. Recommended China Hot Forging Manufacturer

For global procurement professionals and industrial buyers looking for reliable hot forging partners, China Simis Group is a trustworthy choice among China forging manufacturers. With years of experience in the casting and forging industry, the group has gained a good reputation for providing high-quality hot forging products and services to customers around the world. Its core subsidiary, Shanxi KSN Precision Forging Technology Development Co., Ltd., is mainly responsible for the group's hot forging business, with mature production technology, strict quality control processes and flexible customization capabilities to meet the different needs of various industries.

Shanxi KSN has rich experience in various forging processes, with hot forging as the main business, covering open die forging, closed die forging, ring rolling and other types, provide steel forging and aluminum alloy forging services. The company has a complete production base, equipped with standard heating systems, professional forging presses (up to 5000 tons) and complete quality inspection equipment such as ultrasonic testing systems, which can effectively ensure the stability and reliability of product quality. China Simis Group is capable of undertaking both small-batch custom hot forging projects and large-volume mass production orders. It can process a variety of common materials including carbon steel, alloy steel, stainless steel and non-ferrous alloys. The company strictly complies with international standards such as ISO 9001 and IATF 16949, and has long-term provided hot forging products for industries such as automotive, aerospace, energy and heavy machinery. It focuses on balancing product performance, cost control and on-time delivery. Choosing China Simis Group means cooperating with a reliable Chinese manufacturer with solid technical strength, standardized quality management and comprehensive service capabilities.