Custom Valve Manifold Block Manufacturer

Valve Manifold Block

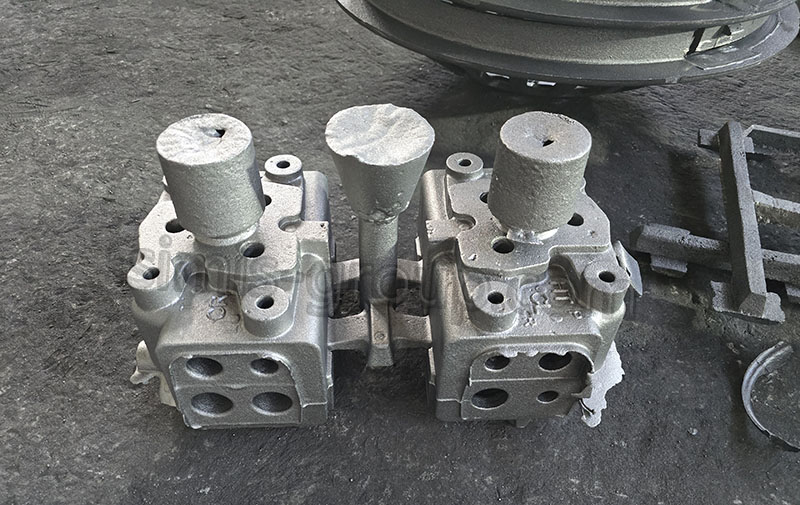

China Simis Company specializes in the custom manufacturing of Manifold Blocks and Valve Blocks characterized by highly complex internal flow paths. These components integrate multiple valves into a single compact unit, reducing plumbing complexity, minimizing leak points, and improving overall system response. We move beyond simple cross-drilling to provide integrated fluidic solutions with curved and multi-level internal channels.

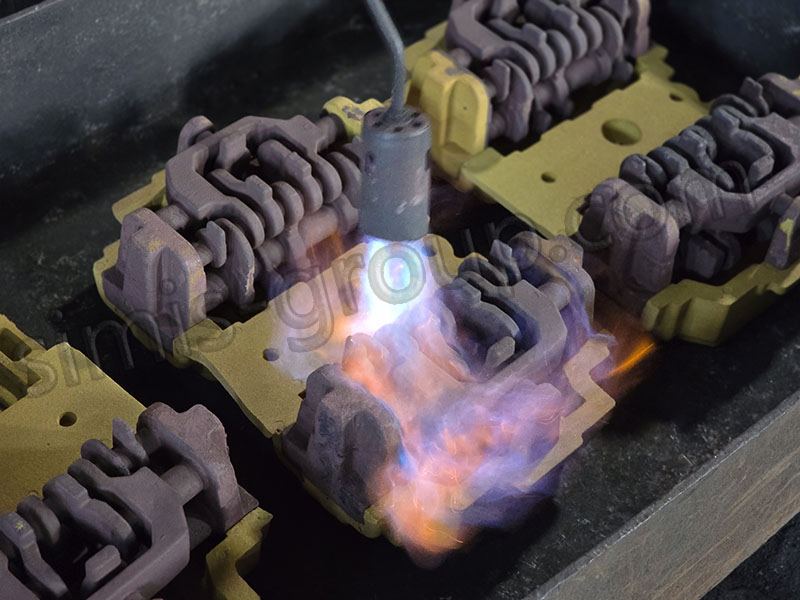

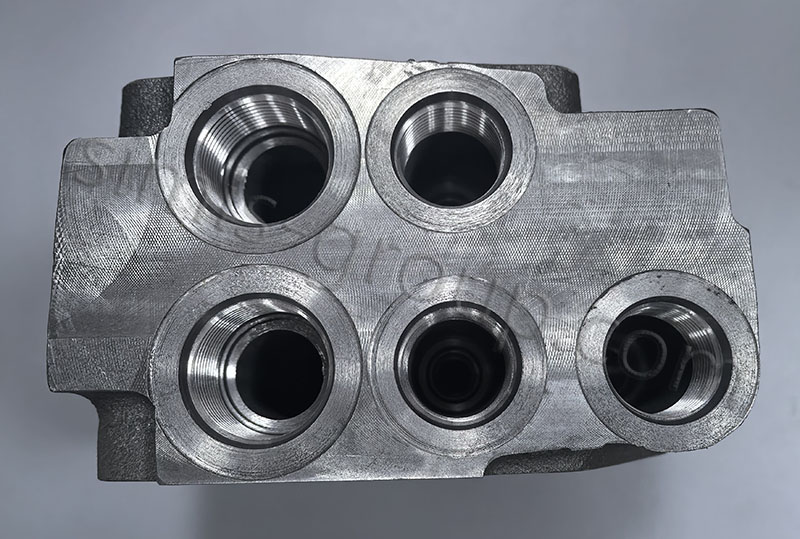

To ensure performance under extreme pressures, we utilize a multi-process manufacturing approach: Ductile Iron and Steel Casting for heavy-duty industrial blocks, Aluminum Gravity Die Casting for lightweight mobile applications.By utilizing Shell Mold Casting, Lost Foam Casting (LFC) and Investment Casting, we can create "un-drillable" internal geometries that optimize flow efficiency and significantly reduce the overall footprint of the block. For ultra-high-pressure applications, we combine Multi-Axis CNC Deep-Hole Machining with specialized deburring to ensure every intersection is surgically clean.

What Manufacturing Processes Are Applied to Valve & Manifold Blocks?

Our company primarily casts manifold blocks and valve blocks with highly complex internal flow channels. For simple channel hydraulic valve blocks, solid blanks can be used via Precision CNC machining.

| Manufacturing Process | Component Focus | Material Focus | Key Advantage for Fluid Performance |

| Lost Foam Casting (LFC) | Complex manifolds with intricate internal cross-drilled channels and ports. | Ductile Iron, Gray Iron. | Internal Complexity. Enables the casting of complex internal flow paths that are difficult or impossible to drill, reducing fluid turbulence. |

| Shell Mold Casting | Consistent production of medium-sized valve bodies and control blocks. | Ductile Iron, Carbon Steel. | Superior Surface Quality. Provides smoother internal casting surfaces than sand casting, reducing flow friction and contamination risks. |

| Gravity Die Casting | Lightweight manifold blocks for automotive and mobile hydraulics. | Aluminum Alloy. | Pressure Tightness. Provides a much denser grain structure than high-pressure die casting, ensuring the block is oil-tight under pressure. |

| Sand Casting (Resin Sand) | Massive industrial manifold blocks for heavy presses and marine systems. | Ductile Iron, Gray Iron. | Robustness for Large Units. The most economical method for manufacturing large-scale blocks with significant wall thicknesses. |

| Investment Casting (Lost Wax) | Small, highly intricate valve blocks with integrated mounting features. | Stainless Steel, Alloy Steel. | Near-Net Shape Precision. Reduces the need for extensive secondary machining while providing excellent corrosion resistance. |

| Deep Hole Drilling & Deburring | All manifold types requiring internal porting. | All Metals. | Clean Flow Paths. Specialized CNC cross-drilling and thermal deburring ensure no burrs remain to damage sensitive valve spools. |

How to Select Materials for Valve & Manifold Blocks?

Choose the appropriate material based on the different usage environments to save economic costs while ensuring that the conditions are met.

| Material Type | Core Performance Attributes | Primary Manifold Application |

| Ductile Iron | High Strength & Excellent Machinability. Resists "ballooning" under pressure. | Industrial Hydraulic Manifolds, agricultural control blocks. |

| Alloy Steel / Carbon Steel | Ultimate Pressure Resistance. Can be hardened for wear-prone valve seats. | High-Pressure Systems (350+ Bar), oil & gas control valves. |

| Aluminum Alloy | Lightweight & High Thermal Conductivity. | Mobile Hydraulics, aerospace valve blocks, and automotive braking systems. |

| Stainless Steel | Maximum Corrosion Resistance. Ideal for aggressive fluids. | Marine Hydraulics, chemical processing, and food industry manifolds. |

What Quality Control Measures Are Adopted for Valve & Manifold Block Complex Channels?

The more complex the internal path, the more rigorous the inspection must be:

·Endoscopic Inspection (Borescope):

Visual verification of every internal intersection and channel surface to ensure they are burr-free and smooth.

·Hydrostatic Pressure Testing:

Validating structural integrity between adjacent channels to prevent internal cross-talk/leakage.

·Helium Leak Testing:

For high-purity or gas manifolds requiring absolute hermetic sealing.

·Flow Bench Testing:

Measuring actual pressure drop across the block to verify it meets CFD (Computational Fluid Dynamics) simulations.

·Ultrasonic / X-Ray Inspection:

Ensuring the casting or billet is free from internal inclusions or porosity that could fail under pressure.

·Cleanliness Verification:

Utilizing specialized flushing and particle counting to ensure internal channels are free of debris.

·Coordinate Measuring Machine (CMM):

Verifying the precise location and depth of every valve cavity and port.

What Are the Key Application Sectors for Valve & Manifold Blocks?

Our complex manifold solutions are engineered for industries where fluid precision and system reliability are non-negotiable:

| Application Sector | Typical Component | Simis Process Focus |

| Construction & Mining | Main Control Valve Blocks for Excavators/Loaders. | Ductile Iron Casting / CNC Machining. |

| Industrial Automation | Hydraulic Power Unit (HPU) Manifolds. | Steel Billet Machining / Lost Foam Casting. |

| Aerospace | Flight Control Manifolds, Landing Gear Blocks. | Billet CNC / Investment Casting. |

| Oil, Gas & Marine | Subsea Manifolds, Offshore Control Blocks. | Stainless Steel Casting / Deep Hole Drilling. |

| Medical & Life Sciences | Zero-dead-volume for precise fluid dosing and chemical compatibility. | Stainless Steel Investment Casting. |

| Mobile Hydraulics | Integrated multi-function blocks for excavators and harvesters. | Ductile Iron Shell Mold Casting. |

| Agricultural Machinery | Harvester Steering and Implement Control Blocks. | Ductile Iron Shell Mold Casting. |

| Injection Molding Machines | High-Speed Clamping and Injection Manifolds. | Ductile Iron Shell Mold Casting. |

What Are the Advantages of Simis OEM Custom Valve Block & Manifold Block?

·Manifold Optimization:

Helping clients transition from bulky pipe-connected systems to compact, integrated manifold blocks.

·Complex Porting Design:

Capability to execute complex cross-drilled and angled porting using 5-axis CNC technology.

·Specialized Deburring:

Using Electrochemical Machining (ECM) or Thermal Deburring to ensure even the most hidden intersections are burr-free.

·Surface Treatments:

Offering Zinc plating, Anodizing, or Phosphating for enhanced corrosion protection in harsh environments.

·Plug-Free Design:

Utilizing casting technology to create internal paths that don't require external drilling access holes, eliminating leak points.

·Material Integrity:

Specialized in Ductile Iron and Alloy Steels to ensure the thin walls between complex channels don't fail under fatigue.

How to Get a Quote for Custom Valve & Manifold Blocks?

China Simis Company provides a full-spectrum solution for Custom Valve Blocks and Manifold Blocks (Iron Casting Services), combining advanced Casting and Precision Machining to deliver leak-free fluid control. From lightweight aluminum blocks to heavy-duty steel manifolds, we ensure your systems operate with maximum efficiency.

To obtain a detailed and accurate technical quotation for your custom valve & manifold block project, please submit the following technical documentation and specifications to our professional engineering team:

2D/3D technical drawings or CAD models with complete hydraulic circuit layouts and GD&T (Geometric Dimensioning and Tolerancing) requirements

Specified working pressure rating, fluid medium (e.g., hydraulic oil, water, chemical fluids), and operating temperature range

Material grade requirements (e.g., Ductile Iron ASTM A536, Stainless Steel 316L, Aluminum Alloy 6061)

Surface treatment specifications (e.g., zinc plating, anodizing, phosphating) for corrosion protection

Annual production volume, target delivery lead time, packaging standards, and shipping destination

Special quality certification requirements (e.g., ISO 9001, CE, API) for industry compliance

Our engineering team will conduct a comprehensive Design for Manufacturability (DFM) analysis, optimize the internal flow path for minimal pressure drop, and deliver a full quotation package covering unit pricing, tooling costs, quality inspection protocols, and global logistics solutions.