Custom ECU Housing Manufacturer

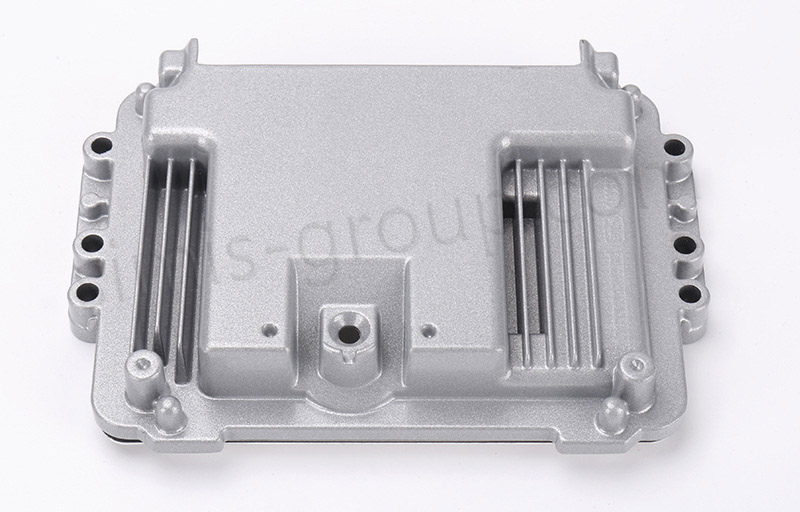

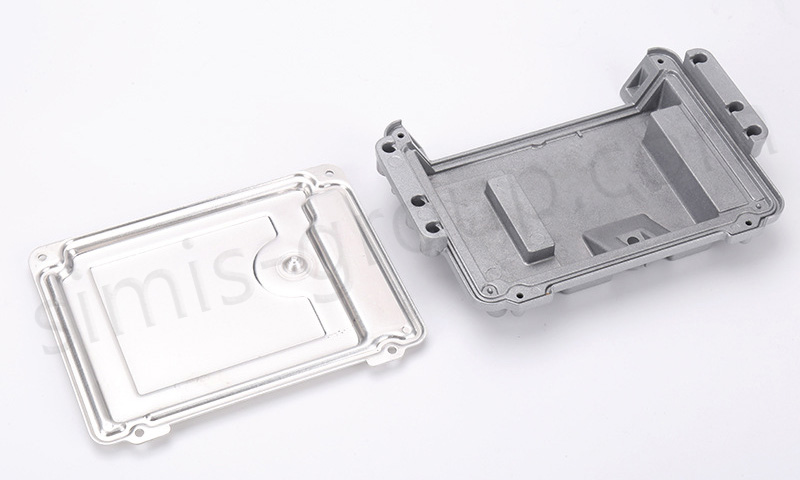

ECU Housing

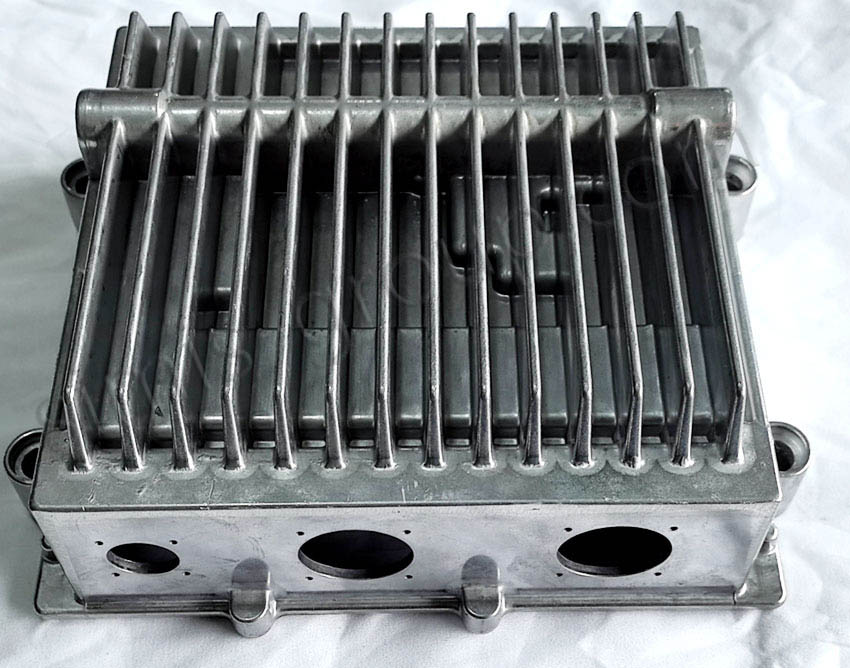

Simis Company is a OEM manufacturer of high-precision Electronic Control Module (ECM) and Engine Control Unit (ECU) Housings. As the protective shell for the "brain" of modern machinery and vehicles, these housings are engineered to safeguard sensitive printed circuit boards (PCBs) from thermal stress, electromagnetic interference (EMI), harsh environmental contaminants, and must withstand extreme under-hood conditions, including high thermal stress, constant vibration, and exposure to automotive fluids.

Our manufacturing focus centers on Aluminum Pressure Die Casting for superior heat dissipation and Precision CNC Machining to ensure airtight sealing. From standard internal combustion engines to EV Inverter/Battery Management System (BMS) enclosures, we utilize advanced Aluminum Alloys and Stainless Steel to deliver housings that meet IP67/IP69K standards and offer exceptional EMI/RFI shielding.

What Manufacturing Processes Are Adopted for ECM/ECU Housings?

For high-volume, complex, thin-walled general-purpose Electronic Control Unit housings that primarily rely on air cooling, high-pressure die casting is the preferred manufacturing process due to its high efficiency and precision. For small-volume, high-performance Electronic Control Unit Housing housings, especially those with integrated liquid-cooled flow channels (such as motor controllers in electric vehicles and high-power DC-DC converters), gravity casting is a more reliable manufacturing process due to its excellent density and heat-treatable properties. In complex environments such as heavy machinery, casting processes using cast iron and steel are more suitable.

| Manufacturing Process | Material Focus | Component Focus | Key Advantage for ECU Performance |

| Pressure Die Casting | Aluminum Alloy (A380, ADC12). | Main Engine Control Unit bodies, cooling fins, and intricate sensor-integrated covers. Mass-produced automotive Electronic Control Modules, heat-dissipating covers, and thin-walled boxes. | Optimal Thermal Dissipation. Allows for thin-walled designs with integrated cooling fins to effectively draw heat away from the PCB. |

| Gravity Permanent Mold Casting | Aluminum Alloy. | High-density control modules requiring superior pressure tightness and strength.Heavy-duty Engine Control Unit housings for trucks, marine engines, or industrial machinery. | Pressure Tightness. Minimizes porosity compared to high-pressure die casting, ensuring reliability in high-pressure or submerged environments. |

| Sand Casting (Resin Sand) | Ductile Iron, Gray Iron. | Heavy-duty Electronic Control Module housings for mining equipment, marine engines, and agricultural machinery. | Extreme Robustness. Provides massive, thick-walled protection against high-impact and high-vibration environments. |

| Shell Mold Casting | Ductile Iron, Carbon Steel. | Medium-duty control modules for commercial vehicles and stationary engines. | Consistency & Surface Quality. Offers a better finish than sand casting, reducing post-cast machining for mounting lugs. |

| Precision Investment Casting | Stainless Steel, Alloy Steel. | Small-scale, highly complex housings for aerospace or high-performance racing. | Precision & Corrosion Resistance. Ideal for intricate geometries where high strength and chemical stability are non-negotiable. |

| Precision CNC Machining | Aluminum Alloy | Gasket grooves, connector mounting ports, and surface leveling. | Airtight Sealing Precision. Crucial for achieving the mirror-finish tolerances required for liquid gaskets and vacuum-tight seals. |

How to Select Materials for ECM/ECU Housings?

Different materials are suited to different application environments; selecting the appropriate material based on the specific application scenario is crucial to realizing its full potential.

| Material Type | Core Performance Attributes | Primary ECU Application |

| Aluminum Alloy | Excellent Thermal Conductivity and high strength-to-weight ratio. | Standard Automotive Electronic Control Units, EV Power Inverters, and Transmission Control Units (TCUs). |

| Stainless Steel | Maximum Corrosion Resistance and high structural integrity. | Marine Engine Control Units and housings exposed to aggressive salt or chemical environments. |

| Alloy Steel | High toughness and customizable hardness through heat treatment. | Heavy-duty Commercial Vehicle control modules and vibration-prone mounting frames. |

| Ductile Iron | Superior Shock Absorption and high compressive strength. | Specialized Heavy Industrial Machinery control housings in mining or construction. |

What Quality Control and Environmental Standards Are Applied to ECM/ECU Housings?

To ensure 100% reliability in the field, our ECM housings undergo a suite of specialized tests:

·Hermetic Leak Testing:

Vacuum decay or helium leak testing to ensure absolute sealing against moisture (IP67/68 compliance).

·Vibration & Mechanical Shock:

Simulating the extreme G-forces found in engine-mounted applications to prevent material fatigue.

·Thermal Cycling Analysis:

Testing the housing under rapid temperature fluctuations to ensure no warping or gasket failure occurs.

·Surface Integrity (NDT):

Utilizing MT/PT for iron/steel and X-Ray for aluminum to detect any porosity that could compromise thermal flow.

What Are the Key Application Sectors for OEM ECM/ECU Housings?

| Application Sector | Typical Housing Type | Simis Process Focus |

| Passenger Vehicles | Powertrain Control Modules (PCM), BMS Housings. | Aluminum Die Casting |

| Electric Vehicles (EV) | Motor Controller Enclosures, DC-DC Converters. | High-Precision Die Casting with integrated cooling. |

| Commercial & Off-Road | Heavy-Duty Diesel Engine ECUs. | Gravity Die Casting / Shell Mold Casting. |

| Marine & Aerospace | Sealed Navigation and Engine Control Modules. | Stainless Steel Investment Casting. |

| Heavy Industry | Mining Equipment Controllers, Hydraulic Control Modules. | Ductile Iron Sand Casting / Shell Mold. |

| Renewable Energy | Solar Inverter Housings, Wind Turbine Controllers. | Aluminum Die Casting / Sheet Metal Fabrication. |

What Are the Advantages of Simis Custom ECM/ECU Housings?

·Integrated Thermal Management:

Custom design of cooling fin arrays and heat pipe interfaces to maximize PCB cooling.

·Design for Manufacturability (DFM):

Assisting clients in optimizing draft angles and wall thicknesses to reduce weight and cost.

·Surface Treatment Optimization:

Providing specialized coatings (Anodizing, E-coating) for specific chemical resistance requirements.

·Vibration Analysis:

Material and geometry selection to ensure the housing acts as a damper for sensitive electronic components.

How to Get a Quote for Custom ECM/ECU Housings?

China Simis Company provides custom industry-leading manufacturing for Electronic Control Module Housings (Aluminum alloy casting services), specializing in Aluminum Die Casting and Precision Machining for the global automotive industry. We ensure every enclosure provides the thermal efficiency and environmental protection necessary for modern vehicle intelligence.

To obtain a precise and detailed technical quotation for your custom ECM/ECU housing project, please submit the following information to our professional engineering team:

2D/3D technical drawings with complete GD&T (Geometric Dimensioning and Tolerancing), including requirements for sealing grooves, connector ports, and mounting surfaces

Thermal load data of the target PCB, operating temperature range, and required heat dissipation efficiency

Specified IP rating (e.g., IP67, IP69K) and EMI/RFI shielding requirements

Material preferences or application-specific material requirements (e.g., corrosion-resistant stainless steel for marine use)

Annual production volume, target delivery lead time, packaging specifications, and shipping destination

Our team will conduct a comprehensive DFM (Design for Manufacturability) analysis, optimize the housing structure for cost and performance, and deliver a full quotation package covering unit pricing, tooling costs, quality inspection protocols, and global logistics solutions.