Custom Air Spring Base Manufacturer

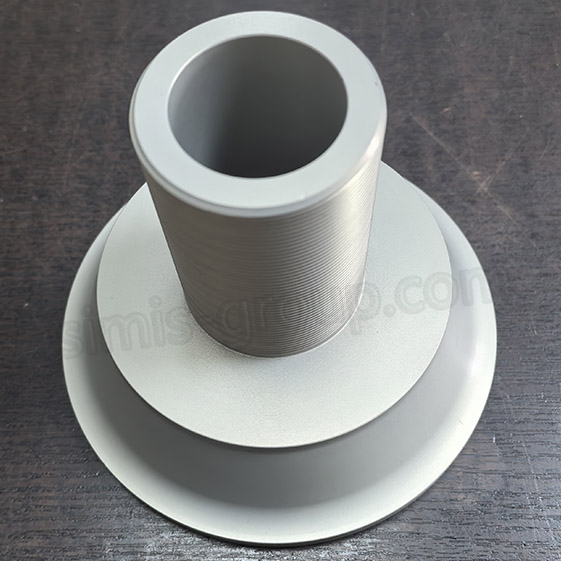

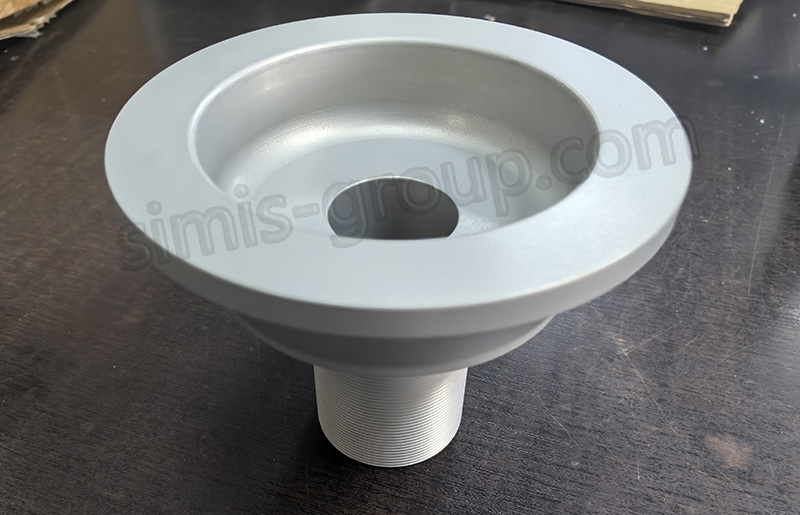

Air Spring Base

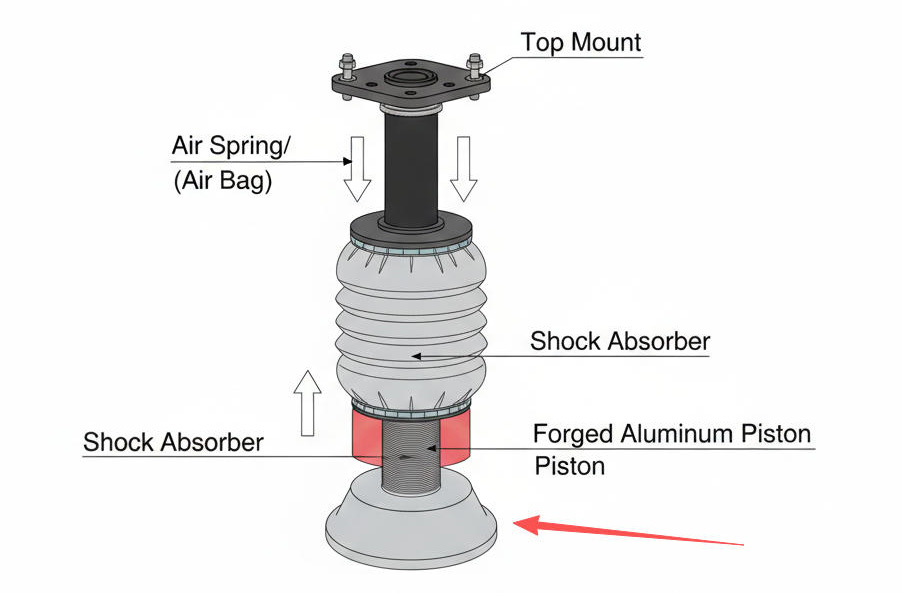

China Simis Company is a specialized manufacturer of critical structural components for automotive air suspension systems. As the automotive industry shifts toward lightweighting and active damping, the Air Suspension Piston and Air Spring Base have become vital for maintaining structural integrity under high-frequency oscillation.

By utilizing Precision Cold/Hot Forging and high-speed CNC Machining, we produce aluminum pistons that offer a 30% weight reduction over traditional steel components without compromising tensile strength. Our parts are engineered to provide the perfect sealing surface for air bellows, ensuring leak-free performance and superior ride dynamics for luxury passenger vehicles and commercial EVs.

What Manufacturing Processes Are Used for Air Spring Base?

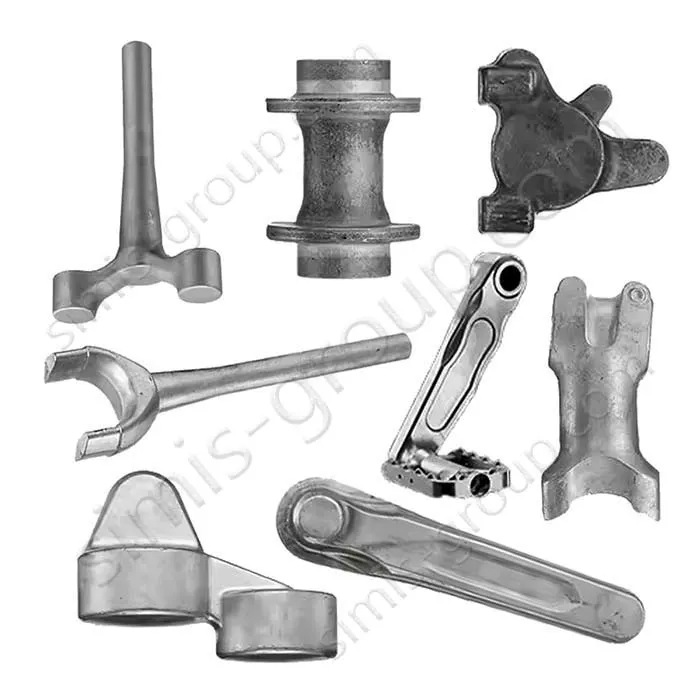

The manufacturing process of Air Spring Base is selected based on component structure, application scenario and material characteristics, and Simis mainly adopts four core processes including precision closed die forging, gravity die casting, CNC machining and impact extrusion, each matched with specific aluminum materials to meet the structural and performance requirements of different air spring base components.

| Manufacturing process | Best For | Material Suitability | Key Engineering Advantage |

| Precision Closed Die Forging | Primary Piston bodies, structural bases. | Aluminum 6061 / 7075. | Structural Integrity. Refined grain flow eliminates internal porosity, essential for high-pressure air containment and fatigue resistance. |

| Gravity Die Casting | Complex mounting brackets for air struts. | Aluminum A356-T6. | Complex Geometry. Suitable for intricate shapes that are difficult to forge, while maintaining high density via T6 heat treatment. |

| CNC Machining | O-ring grooves, valve seats, mounting threads. | Forged Aluminum Blanks. | Micron-Level Precision. Ensures perfect concentricity and surface finish (Ra 0.4) for airtight rubber-to-metal sealing. |

| Impact Extrusion | Thin-walled cylindrical pistons. | Aluminum 6000 series. | High Efficiency. Ideal for producing deep-drawn cylindrical shapes with consistent wall thickness and high material utilization. |

How to Select Materials for Air Spring Base?

Material selection for Air Spring Base is based on the application stress, corrosion resistance requirements and structural form of the component, Simis mainly uses forged aluminum, high-strength aluminum, cast aluminum and stainless steel series materials, all of which meet the international grade standards and are matched with the corresponding air suspension components to ensure the overall performance and service life of the product.

| Material Category | International Grades | Key Attributes | Application in Suspension |

| Forged Aluminum | 6061-T6 | Excellent corrosion resistance and high toughness; the industry standard for durability. | Main Piston Body, Lower Strut Mounts. |

| High-Strength Aluminum | 7075-T6 | Aircraft-grade strength; used for performance/racing air suspension systems. | High-stress Air Spring Bases, Top Mounts. |

| Cast Aluminum | A356.0-T6 | Good castability and pressure tightness; easily heat-treated for structural use. | Air Spring Upper Caps, Complex Brackets. |

| Stainless Steel | AISI 304 / 316 | Maximum corrosion protection; used for specialized hardware and fasteners. | Air Intake Fittings, Sealing Rings. |

What Precision CNC Machining & Surface Engineering Are Applied to Air Spring Base?

Airtightness is the core requirement of Air Spring Base in the air suspension system, so Simis has developed a set of targeted high-precision CNC machining and surface engineering processes for the key sealing and friction parts of the base, which effectively ensure the airtight performance and wear resistance of the product in complex working conditions.

·High-Precision Turning:

Machining of O-ring grooves and sealing seats with a surface roughness of Ra 0.4 - Ra 0.8 to prevent air leakage.

·Hard Anodizing (Type III):

Creating a wear-resistant oxide layer to protect the aluminum piston from friction against the air bellow and environmental salt/debris.

·Pressure Testing Ports:

CNC drilling and tapping of air intake ports with specialized thread profiles (NPT/Metric) for high-pressure fittings.

·Leakage Detection Surfaces:

Precision milling of the base contact area to ensure a 100% flat surface for the rubber diaphragm interface.

What Quality Control & Performance Validation Are Adopted for Air Spring Base?

Simis has formulated a strict and comprehensive quality control and performance validation system for Air Spring Base, covering 100% full inspection of key performance indicators and sampling detection of long-term durability, and conducting multi-dimensional tests from air tightness, dimensional accuracy, corrosion resistance to fatigue resistance to ensure that each product meets the application requirements.

·Air Leakage Test:

100% of pistons and bases are tested under high-pressure submersion to ensure zero bubbles at the sealing interface.

·CMM Dimensional Audit:

Verification of critical diameters and groove depths to ensure compatibility with rubber bellows.

·Salt Spray Test:

480-720 hours of salt spray testing to validate the durability of the anodized coating against winter road salts.

·Fatigue Testing:

Simulating millions of compression cycles to ensure the forged aluminum does not develop stress cracks.

What Are the Industry Applications for OEM Custom Air Spring Base?

Simis's Air Spring Base has a wide range of applications in the automotive industry, and is customized with different performance configurations according to the characteristics of different sectors such as luxury passenger cars, electric vehicles, commercial trucks and auto aftermarket tuning, to meet the personalized suspension performance requirements of various vehicle types.

| Sector | Component Use | Performance Requirement |

| Luxury Passenger Cars | Active Air Struts. | High NVH (Noise, Vibration, Harshness) damping and lightweighting. |

| Electric Vehicles (EV) | Battery-Compensating Suspension. | Weight reduction to extend battery range while supporting high chassis loads. |

| Commercial Trucks | Cabin & Axle Air Springs. | Extreme fatigue life (>5 million cycles) and heavy-load capacity. |

| Auto Aftermarket Tuning | Performance Air Shocks. | Aesthetic finishing (Anodizing) and adjustable height compatibility. |

What Are the Advantages of Simis Custom Air Spring Base?

As a strategic engineering partner in the air suspension industry, Simis's custom engineering and OEM solutions for Air Spring Base have comprehensive competitive advantages covering co-development, precision tooling, material customization, surface treatment, scalable production and vertical integration, and can provide one-stop customized services for customers of different scales and needs.

·Co-Development & DfM (Design for Manufacturability):

Our engineering team works directly with your R&D department to refine part geometries. By applying DfM principles, we optimize the forging grain flow and reduce CNC cycle times, resulting in a stronger part with lower production costs.

·Precision Tooling Design:

We design and manufacture our own forging dies and CNC fixtures in-house. This allows for rapid prototyping (NPI) and ensures that even the most complex internal chambers of a Suspension Piston are formed with consistent wall thickness.

·Material Customization:

Beyond standard 6061-T6, we offer high-strength 7075 alloys for performance vehicles or specialized DZR alloys for extreme environmental resistance. We provide full material traceability with 3.1 chemical and mechanical test reports.

·Advanced Surface Customization:

We provide a wide range of functional finishes, including Hard Anodizing (Type III) for wear resistance, PTFE Coating for ultra-low friction, and custom color anodizing for brand-specific aftermarket kits.

·Scalable Production (From Proto to Mass):

Whether you require a small batch of 500 pieces for high-end boutique car brands or high-volume production exceeding 100,000 units for mass-market EVs, our automated forging lines and CNC cells scale to meet your demand.

·Vertical Integration:

From raw aluminum billet to forged blank, precision machining, surface treatment, and final leak testing—Simis handles the entire lifecycle. This minimizes your supply chain risk and ensures a single point of accountability for quality.

How to Get a Quote for OEM Custom Air Spring Base?

To get a detailed and accurate technical quotation for custom Air Spring Base, you only need to submit the relevant technical documents and project requirements to Simis's professional engineering team, and we will provide a one-stop quotation package and free technical support according to your needs, with efficient response and professional solution customization.

2D/3D technical drawings (CAD/STEP/IGS) with complete GD&T (Geometric Dimensioning and Tolerancing) requirements

Specified material grade and heat treatment requirements (e.g., 6061-T6/7075-T6/A356-T6)

Surface treatment and finishing demands (e.g., Hard Anodizing Type III, PTFE Coating, custom color anodizing)

Annual production volume, MOQ requirements and target delivery lead time

Application scenarios and performance indicators (e.g., pressure rating, fatigue cycle, corrosion resistance)

Industry certification requirements (e.g., automotive industry IATF 16949)

Special customization needs (e.g., integrated structural design, brand logo marking)

Our engineering team will respond to your quotation request within 2 working days and provide free technical communication and design optimization suggestions to ensure the product performance and manufacturing cost reach the optimal balance.