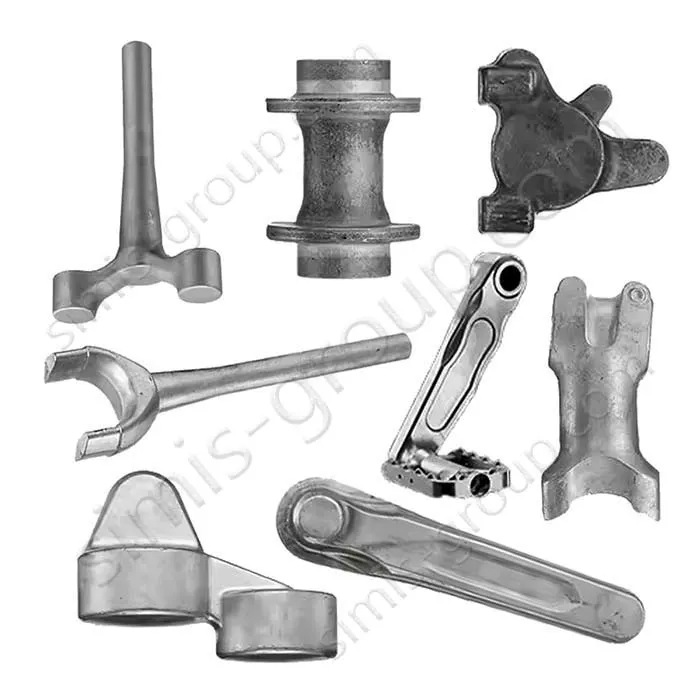

Custom Link Arm Manufacturer

Link Arm

China Simis Company is an experienced OEM custom manufacturer of Link Arms (including Control Arms, Tie Rods, and structural links). These components are Safety-Critical elements of steering, suspension, power transmission, and specialized articulation systems. They are subjected to constant, high-frequency cyclic fatigue loading, tensile/compressive stress, and impact forces.

We utilize Precision Forging for materials demanding the highest fatigue resistance and strength-to-weight ratio (Alloy Steel, Aluminum, Stainless Steel), which is essential for automotive, EV, and heavy machinery. We employ diverse Specialized Casting methods—including Lost Foam Casting (LFC) for large, complex structures and Investment Casting for high-precision, small-to-medium parts in special alloys. Our manufacturing focus is on certified Cyclic Fatigue Life, verified Structural Toughness, and ultra-precise bore alignment for accurate motion transfer, particularly for demanding fields like Medical Equipment and Railways.

What are the manufacturing processes for Link Arm?

The process selection is tailored to the component's function: Forging for maximum strength, and specific Casting methods for precision or complex structure. Each process is engineered to enhance the core performance of link arms under high cyclic fatigue and impact loads.

| Manufacturing Process | Component Focus | Material Focus | Key Advantage for Link Arm Performance |

| Precision Closed Die Forging | Control Arms, Tie Rod Ends, Critical Suspension Links. | Alloy Steel, Aluminum Alloy, Stainless Steel. | Maximum Fatigue Resistance and Toughness. Essential for high cyclic stress in automotive and heavy equipment applications due to optimized grain flow. |

| Sand Casting / Shell Mold Casting | Large Industrial Links, Heavy Equipment Rocker Arms. | Ductile Iron (A536), Cast Steel. | Cost-Effective for Bulk and Complexity. Suitable for large, heavy-duty structural links and complex shapes where ultimate fatigue limits are managed via design. |

| Investment Casting | Small Precision Medical/Sports Links, High-Alloy Fittings. | Stainless Steel (316, 17-4PH), Special Alloys. | Highest Precision and Surface Finish. Excellent for intricate, small links requiring tight tolerances and superior corrosion resistance (Medical/Marine). |

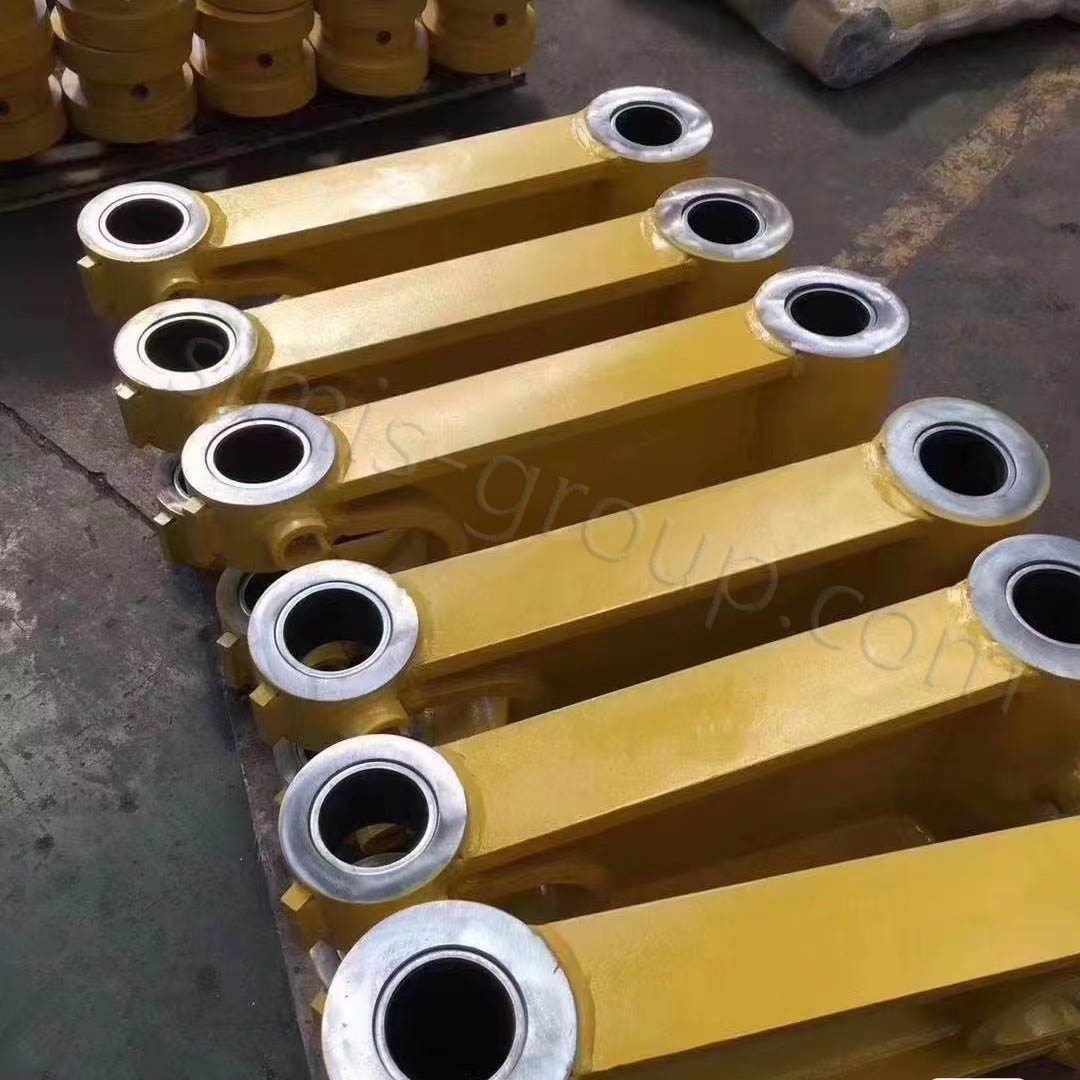

| Lost Foam Casting (LFC) | Large, Complex Structural Links, High-Volume Arms. | Ductile Iron, Cast Steel. | High Cost-Effectiveness and Near-Net Shape. Ideal for complex shapes in high-volume production where material is Ductile Iron. |

| Precision CNC Machining | Bore Alignment, Bushing/Ball Joint Seats, Threaded Ends. | All Materials. | Critical for Motion Accuracy. Ensures ultra-tight tolerances on all interfaces to prevent play and maximize joint service life. |

| Welding and Assembly | Fabricated Control Arms, Assembled Links. | Steel, Aluminum. | Ensures robust joint integrity for assembled link arms, verified by NDT (Non-Destructive Testing). |

What Materials Ensure Link Arm Fatigue Strength, Toughness, and Corrosion Resistance?

Material selection must balance high yield strength and fatigue limits with required impact toughness and environmental resistance. Each material grade is matched to the specific load and environmental demands of the link arm application.

| Material Type | Primary Performance Requirement | Typical Link Arm Component & Service |

| Alloy Steel (AISI 4140, 8620) | Maximum Fatigue Life, High Tensile Strength (After Forging/HT). | Forged Control Arms and Steering Links for commercial vehicles and railways. |

| Aluminum Alloy (6061, 7075) | Maximum Strength-to-Weight Ratio, Corrosion Resistance. | Forged/GDC Links for EV suspension, Motorcycles, and Sports Equipment. |

| Ductile Iron (ASTM A536) | Excellent Castability for Complex Shapes, High Toughness (Compared to Gray Iron). | Cast Lower Control Arms and Heavy Equipment Links where cost and complexity favor casting. |

| Carbon Steel (AISI 1045) | Good Structural Strength, Cost-Effective, Excellent Weldability. | Fabricated or Forged Links for agricultural machinery and standard vehicles. |

| Stainless Steel (304, 316) | Corrosion Resistance for Marine/Medical/Chemical Environments. | Links used in shipbuilding, specialized medical equipment, or harsh environments. |

What Quality Assurance and Structural Safety Certification Apply to Link Arms?

QA protocols focus on verifying structural integrity under cyclical stress and ensuring dimensional accuracy for safe motion control. All testing procedures comply with international industry standards to guarantee the reliability of safety-critical link arm components.

·Cyclical Fatigue Testing:

Links are subjected to Axial and Bending Fatigue Testing (simulating service loads) to verify compliance with OEM and industry standards (SAE, JIS).

·Structural Integrity (NDT):

MPI (Magnetic Particle Inspection) or Dye Penetrant Inspection verifies surface integrity, particularly around highly stressed features like mounting holes and weld zones.

·Material Toughness:

Charpy V-Notch Impact Testing is performed on materials intended for off-road or mining applications to verify resistance to brittle fracture.

·Dimensional and Positional Control:

CMM verification is critical for hole center distance, bore coaxiality, and parallelism to ensure accurate suspension/steering geometry and medical device function.

What are the application areas for custom Link Arm Components?

SIMIS specialize in link arms tailored to the specific demands of the intended system, including the high standards of the medical sector. Component categorization is based on application scenarios and corresponding load characteristics to ensure optimal performance.

| Application Category | Component Focus | Primary Load Type | Ideal Process/Material Focus |

| Automotive/EV/Motorcycle | Control Arms, Tie Rods, Suspension Links. | High Cyclic Fatigue, Bending, Strength-to-Weight. | Forged Aluminum or Forged Alloy Steel. |

| Construction/Mining/Rail | Track Links, Stabilizer Bars, Heavy Articulation Links. | High Impact, Extreme Tensile/Compressive Stress, Fatigue. | Forged Alloy Steel (Toughness) or Cast Ductile Iron (LFC). |

| Medical/Precision | Robotic Arm Links, Articulating Brackets. | Motion Precision, Corrosion Resistance, Cleanliness. | Investment Cast Stainless Steel (316) or Forged Aluminum. |

What Are the Advantages of Simis OEM Custom Link Arm Manufacturing?

Simis delivers certified link arms that ensure reliable motion control, superior handling, and maximum structural safety across diverse industries. Our core advantages are derived from specialized manufacturing processes and strict quality control systems.

·Fatigue-Optimized Manufacturing:

We utilize Precision Forging for all safety-critical, high-stress links, guaranteeing a material structure that provides superior fatigue life.

·Corrosion & Biocompatibility Expertise:

We provide precision manufacturing for Forged and Investment Cast Stainless Steel grades, meeting the stringent corrosion resistance requirements of marine and medical equipment.

·Geometric Precision for Motion:

Our specialized CNC machining protocols ensure the perfect alignment and tolerance of bore centers, maximizing the accuracy and service life of the linkage system.

·Process Flexibility:

We offer specialized solutions across the spectrum, from the highest strength Forged Steel to the highest precision Investment Cast Stainless Steel components.

How to Get a Quote for Custom Link Arm Manufacturing Services?

China Simis Company is your expert global partner for custom forging and casting Link Arms, engineered for safety-critical structural integrity, high cyclic fatigue resistance, and ultra-precise motion control. To obtain a detailed and accurate quotation for your custom link arm project, please submit the following technical documents and specifications to our professional engineering department:

2D technical drawings or 3D CAD models with complete dimensional tolerances

Specific application scenarios (e.g., Automotive Control Arm, Medical Robotic Link, Mining Equipment Track Link)

Expected cyclic load parameters (kN or lbs) and required fatigue test cycles

Target material grade (e.g., AISI 4140 Alloy Steel, 7075 Aluminum Alloy, 316 Stainless Steel)

Surface treatment requirements and quality certification standards

Expected annual production volume and delivery timeline

Our engineering team will conduct a comprehensive feasibility analysis, offer design optimization recommendations to enhance fatigue resistance and structural toughness, and provide a full quotation package covering unit pricing, tooling costs, production lead time, quality control protocols, and delivery terms.