Custom Metal Castings & Forgings Manufacturer

SIMIS Group Company Profile

Metal Castings Foundry & Forgings Factory In China

Simis Group is located in Taiyuan, Shanxi Province, China. The Group includes Taiyuan SIMIS Investment Casting Co., Ltd., and Shanxi KSN Precision Forging Technology Development Co., Ltd.

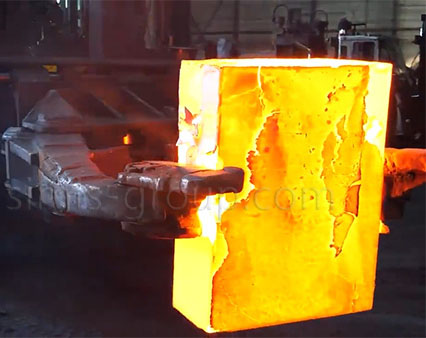

With the continuous development of the company and the continuous expansion of its business, by 2021, SIMIS has developed into a group company of a certain scale, and our process has also developed from the early single investment casting process to the current sand casting, investment casting, shell casting, lost foam casting, free forging, die forging and other metal casting and forging processes.

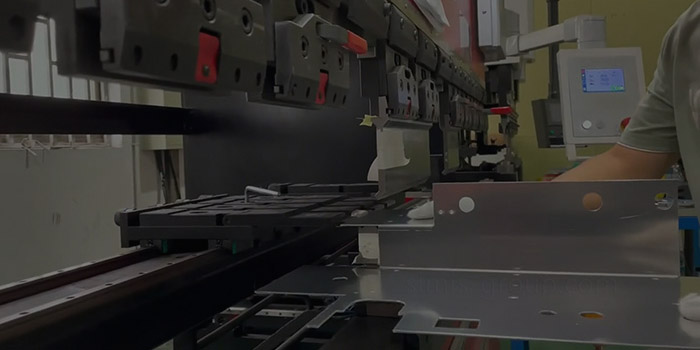

Now, we have 6 foundries, 2 forging factories, 1 professional machining workshop and 1 sheet metal processing workshop.

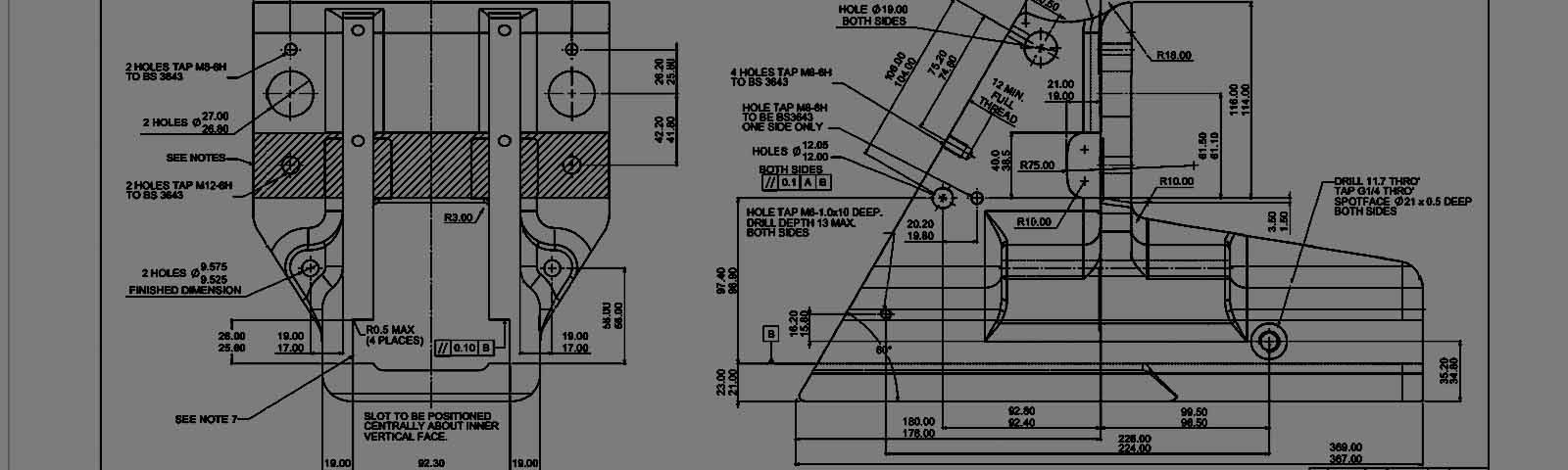

Different metal materials can be made into parts with different properties through different casting and forging processes, and are used in different industries. As a professional OEM custom casting and forging manufacturer, Simis Group provides custom casting and forging processing services for a variety of metal materials to meet the needs of different customers for parts in different industries.

Iron has good casting performance and wear resistance, rough surface, high hardness, suitable for bearing greater pressure and impact.

Steel has excellent toughness and plasticity, a smooth surface and a dense structure, making it suitable for manufacturing high-precision and high-strength parts.

Aluminum alloy is light in weight, high in strength, corrosion-resistant and has good thermal conductivity, making it suitable for manufacturing complex shapes and thin-walled parts.

Other metals such as titanium alloys and copper alloys have their own unique properties, such as high strength, high temperature resistance or excellent conductivity, and are often used in high-end manufacturing fields.

Material

Different metal materials can be made into parts with different properties through different casting and forging processes, and are used in different industries. As a professional OEM custom casting and forging manufacturer, Simis Group provides custom casting and forging processing services for a variety of metal materials to meet the needs of different customers for parts in different industries.

Iron has good casting performance and wear resistance, rough surface, high hardness, suitable for bearing greater pressure and impact.

Steel has excellent toughness and plasticity, a smooth surface and a dense structure, making it suitable for manufacturing high-precision and high-strength parts.

Aluminum alloy is light in weight, high in strength, corrosion-resistant and has good thermal conductivity, making it suitable for manufacturing complex shapes and thin-walled parts.

Other metals such as titanium alloys and copper alloys have their own unique properties, such as high strength, high temperature resistance or excellent conductivity, and are often used in high-end manufacturing fields.

Main Products & Services

Casting Services

Forging Services

Heat Treatment

Surface Treatment

Industries Served

We have more than 400,000 square meters of raw material storage workshops, factories, mold workshops, inspection workshops, processing workshops, warehouses and laboratories, as well as a series of professional and advanced automated production lines and processing centers, and experienced employees to meet the high-quality requirements of different customers for different products.

Factory Display

We have over 500,000 square meters of workshop,warehousing and production facilities. We have automatic moulding machine lines, CNC machining center, professional laboratory, in-house pattern & tooling shops and most important - a group of highly experienced and technically qualifed staff.

Contact Us

If you need customized metal casting and forging products, you can contact us by submitting the website form online or sending an email. We will confirm the quotation details with you within 48 hours and you will get a simis free quotation.